Round billet induction heating

Round billet induction heating Round steel medium frequency heating equipment

Round steel medium frequency heating equipment Round steel medium frequency heating furnace

Round steel medium frequency heating furnace Round steel medium frequency heating forging equipment

Round steel medium frequency heating forging equipment  Round steel medium frequency induction heating furnace

Round steel medium frequency induction heating furnace round steel local intermediate frequency heating furnace

round steel local intermediate frequency heating furnace Round steel local heating electric furnace

Round steel local heating electric furnace  round steel induction heating furnace

round steel induction heating furnace round steel forged heating furnace

round steel forged heating furnace Round bar heating system

Round bar heating system Round bar forging equipment

Round bar forging equipment Φ80 round bar forging furnace

Φ80 round bar forging furnace Round bar medium frequency induction heating furnace

Round bar medium frequency induction heating furnace  Round steel heating furnace

Round steel heating furnace Round steel heating forging equipment

Round steel heating forging equipment  Round steel induction heating furnace

Round steel induction heating furnace Round Bar Forged Medium Frequency Induction Heating Furnace

Round Bar Forged Medium Frequency Induction Heating FurnaceThe whole set of equipment for round steel partial heating electric furnace is controlled by PLC programmable operation table. The equipment is highly automated. The heating temperature of the workpiece is measured by infrared thermometer. The data is transferred to PLC , the power supply is automatically adjusted, and the heating temperature of the workpiece is adjusted. Strong control. In addition, the whole set of metal heat treatment equipment can be equipped with automatic feeding, discharge mechanism, closed cooling tower, low voltage electric cabinet and so on.

Summary of technical parameters of round steel local heating electric furnace

Summary of technical parameters of round steel local heating electric furnace withpower less than 1000KW | |||||||

Rated power(KW ) | Rated frequency (HZ) | Transformer capacity (KVA) | Secondary voltage (V) | Number of commutating pulses | Sensor voltage(V) | Power consumption (KW.h/t) | Round steeldiameter ( mm ) |

80 | 1000~8000 | 100 | 380v | 6 Pulse | 800 | 450 | Φ 6-35 |

100 | 1000~8000 | 160 | 380v | 6 Pulse | 800 | 450 | Φ 25-40 |

120 | 1000~8000 | 200 | 380v | 6 Pulse | 800 | 450 | Φ 30-50 |

160 | 1000~8000 | 250 | 380v | 6 Pulse | 800 | 450 | Φ 40-60 |

200 | 1000~8000 | 315 | 380v | 6 Pulse | 800 | 450 | Φ 40-60 |

250 | 1000~8000 | 400 | 380v | 6 Pulse | 800 | 450 | Φ 60-80 |

350 | 1000~8000 | 500 | 380v | 6 Pulse | 800 | 450 | Φ 80-120 |

400 | 500~8000 | 500 | 380v | 6 Pulse | 800 | 450 | Φ 80-120 |

500 | 500~8000 | 630 | 380v | 6 Pulse | 800 | 450 | Φ 120-150 |

1000 | 500~1000 | 1250 | 660V-380V | 12 Pulse | 1200 / (800) | 380 | Φ 150-250 |

1500 | 500~1000 | 1600 | Φ 660V-380V | 12 Pulse | 1200 / (800) | 370 | Φ 250-400 |

2000 | 500~1000 | 2200 | Φ 660V-380V | 12 Pulse | 1200 / (800) | 360 | Φ 400-800 |

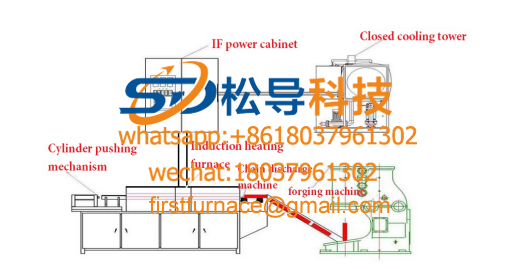

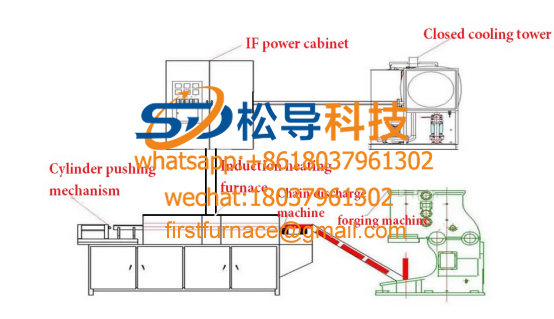

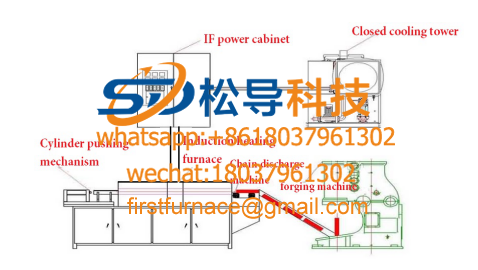

Round steel local heating electric furnace application assembly drawing

Round steel local heating electric furnace application field:

Forging heating: used for round steel, round steel, square steel, steel plate heating, temperature compensation, blue quenching, on-line heating, local heating, metal material online forging (such as gears, semi-shaft connecting rods, bearings, etc.) Extrusion, hot rolling, heating before shearing, spray heating, thermal assembly, and heating, annealing, tempering, etc. of the entire metal material.

Heat treatment: mainly for shafts (straight shaft, variable diameter shaft, camshaft, crankshaft, gear shaft, etc.); gears; sleeves, rings, discs; machine tool screws; guide rails; planes; ball heads; hardware tools, etc. Surface heat treatment of mechanical (automobile, motorcycle) parts and heating, annealing, tempering, etc. of the entire metal material.

What parameters are required for the selection of round steel local heating electric furnace?

The selection of round steel local heating electric furnace generally requires the following parameters:

First: the shape of the heated workpiece, the outer dimensions, and the weight of the heated workpiece.

Second: the material material of the heated workpiece (generally induction heating, only for metal conductor materials).

Third: the time of the target temperature required for heating the heated workpiece, and the target temperature.

Once the above three points are clear, the round steel local heating electric furnace can be selected including matching power.

What are the characteristics of the round steel local heating electric furnace structure?

1. Furnace structure: Our company's heating furnace is designed as an overall quick change type. Quick change is possible when changing the furnace body for different heated workpieces.

2. Furnace lining: The lining is made of silicon carbide or integral knotting, and the temperature is above 1450 °C.

3. Protection: Automatic shutdown when the water temperature exceeds 65 °C.

4. Induction furnace water cooling rail: Water-cooled rail is installed on the induction furnace lining.

How to calculate the power of the local heating electric furnace of round steel?

P=(0.168×200×693)/(0.24×0.6×145)=1029KW In the formula: 0.168—the average specific heat of the ferrous metal; 2080—the mass of the workpiece (Kg); 200—the temperature rise of the workpiece heating; 0.24— Work heat equivalent; 0.6 - average efficiency (0.6 in this case, generally 0.5 ~ 0.65, lower profile sensor, take 0.4); 145 - work beat (seconds)

According to the above calculation, a 1KHz induction heating device with a rated power of 1500 KW can be configured to meet the needs.

How to choose the power frequency of the local heating electric furnace of round steel?

The choice of power frequency follows the principle of optimal heating efficiency and temperature uniformity (core temperature difference). The higher the frequency, the higher the heating efficiency, but the too high frequency is likely to cause the surface of the workpiece to be too burnt. According to our experience, the frequency is selected to be 2500KHZ. , the best heating effect can be obtained without overheating the workpiece temperature.

How to choose and use round steel local heating furnace? Mainly from several aspects:

1. Shape and size of the heated workpiece

For large workpieces, round steels and solid materials, round steel local heating furnaces with relatively high power and low frequency should be used; for small workpieces, pipes, plates, gears, etc., round steel partial heating electric furnace with low relative power and high frequency should be used.

2. Depth and area required for heating

Deep heating depth, large area, overall heating, should choose high-power, low frequency round steel local heating electric furnace; shallow heating depth, small area, local heating, the use of relatively low power, high frequency round steel local heating furnace.

3, the required heating rate

The required heating speed is fast, and a round steel local heating electric furnace with relatively large power and relatively high frequency should be selected.

4, the continuous working time of the equipment

The continuous working time is long, and the round steel local heating electric furnace with slightly larger power is used.

5, the connection distance between the sensing component and the device

The connection length is long, and even the use of water-cooled cable connection is required. The medium-frequency induction heating furnace with higher power should be used relatively.

6, process requirements

In general, quenching, welding and other processes, relatively power can be selected smaller, frequency selection is higher; annealing, tempering and other processes, relative power selection is larger, frequency selection is lower; red punch, hot calcination, smelting, etc., need For a heating process, the power should be chosen to be larger and the frequency selected lower.

7, the material of the workpiece

The relative power of the high melting point of the metal material is larger, the relative power of the lower melting point is smaller, the power of the smaller resistivity is larger, and the power of the larger resistivity is smaller.

Round steel local heating electric furnace has significant advantages:

1. Compared with traditional heating means (oil, coal, gas), it has the remarkable advantages of environmental protection, energy saving, convenient operation and low labor intensity;

2. Compared with the thyristor intermediate frequency, the energy saving is 10%~30%, and there is no harmonic interference to the power grid;

3. Compared with the resistance furnace, the energy saving is 50%~60%;

4. It has the advantages of fast heating, uniform heating, no oxide layer and good product quality for customers' products;

5. The sensor is isolated by a transformer and is very safe.

6. Environmental protection: no pollution, noise and dust.

7. Adaptability: It can heat various workpieces with different shapes.

8, the equipment occupies a small area, less than two square meters, to facilitate customers to maximize the use of production space.

Why is the round steel local heating electric furnace high efficiency?

The principle of the local heating electric furnace of round steel is electromagnetic induction, and the heat is generated in the workpiece itself. The ordinary workers can carry out the continuous work of the forging task ten minutes after the work of the local heating electric furnace of the round steel , and the professional workers do not need to burn the furnace in advance. Sealing the furnace work. Don't worry about the waste of the heated billet caused by the power outage or equipment failure. Because the heating method has a fast heating rate, the oxidation is very rare, and at least the steel raw material is saved per ton of forgings compared with the coal burning furnace. 50 kg, its material utilization rate can reach 95%. Because the heating method is evenly heated, the core surface temperature difference is very small, so the forging die life is greatly increased in forging, and the surface roughness of the forging piece is also less than 50um. Induction heating The heat is generated in the workpiece itself, so the heating is uniform, and the temperature difference between the core and the core is very small. The temperature control system can realize the precise control of the temperature to improve the product quality and the pass rate.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved