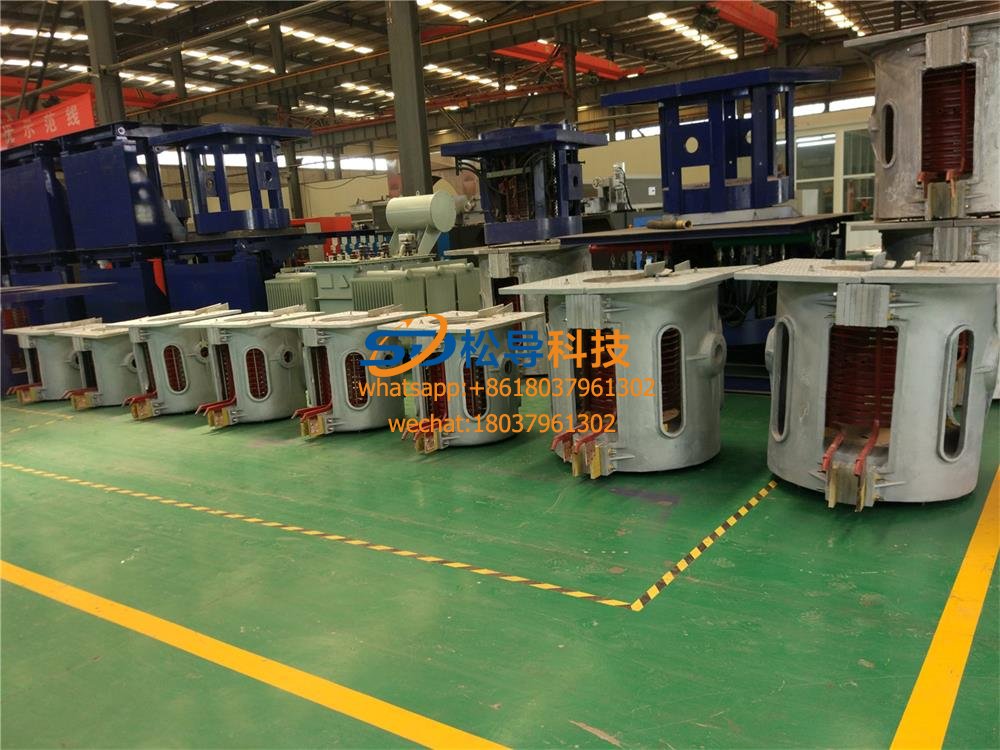

5T intermediate frequency melting furnace

5T intermediate frequency melting furnace 3T intermediate frequency melting furnace

3T intermediate frequency melting furnace 2T intermediate frequency melting furnace

2T intermediate frequency melting furnace 1T intermediate frequency melting furnace

1T intermediate frequency melting furnace Steel shell intermediate frequency melting furnace

Steel shell intermediate frequency melting furnace Aluminium Shell Intermediate Frequency Melting Furnace

Aluminium Shell Intermediate Frequency Melting Furnace intermediate frequency melting furnace

intermediate frequency melting furnace 0.75T Intermediate Frequency Melting Furnace

0.75T Intermediate Frequency Melting Furnace 0.5T Intermediate Frequency Melting Furnace

0.5T Intermediate Frequency Melting Furnace 250kg medium frequency melting furnace

250kg medium frequency melting furnaceThe intermediate frequency melting furnace is mainly composed of four parts :

1 , power and electrical parts: parallel inverter intermediate frequency power supply or series inverter intermediate frequency power supply

2 , the furnace part: aluminum shell or steel shell, steel shell furnace body consists of furnace shell, fixed frame, furnace cover, tilting furnace mechanism, induction coil, yoke, etc., leaking furnace alarm device.

3 , transmission: mechanical reducer or hydraulic device.

4 , water cooling system: closed loop cooling tower

The selection of the power of the intermediate frequency melting furnace , the selection of the capacity of the intermediate frequency melting furnace, and the selection method of the power consumption of the intermediate frequency melting furnace.

model | unit | SDBLR - 1 00 kw | SDBLR - 2 00 kw | SDBLR - 4 00 kw | SDBLR - 8 00 kw | SDBLR - 16 00 kw | SDBLR - 20 00 kw | SDBLR - 30 00 kw |

Capacity selection | T | 0.1 | 0.25 | 0.5 | 1 | 2 | 3 | 5 |

Rated temperature | °C | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 |

IF power | Kw | 100 | 200 | 400 | 800 | 1600 | 2000 | 3000 |

IF voltage | V | 750 | 750 | 1500 | 1500 | 3000 | 3000 | 3200 |

IF frequency | KHz | 2.5 | 1 | 1 | 1 | 1 | 1 | 0.5 |

Power consumption selection | Kwh/t | 830 | 700 | 650 | 600 | 600 | 550 | 550 |

Flip type | mechanical | mechanical | mechanical | Hydraulic | Hydraulic | Hydraulic | Hydraulic | |

Transformer selection | KVA | 100 | 200 | 500 | 1000 | 1500 | 1600 | 3150 |

Water cooling tower selection | ZXZ | ZXZ- 10T | ZXZ- 20T | ZXZ- 40T | ZXZ- 80T | ZXZ- 140T | ZXZ- 160T | ZXZ- 240T |

The price of the intermediate frequency melting furnace

Price IF melting furnace is probably in a few million each, there are thousands of dollars cheaper, we have hundreds of thousands of dollars. The price of medium frequency melting furnaces is affected by many factors, such as brand, category, specifications, market and so on. It is necessary to understand and compare in many aspects before choosing to buy. The technical parameters of the intermediate frequency melting furnace are different, and the price is different. It is calculated according to the power of the intermediate frequency power supply and the volume of the furnace body. Different configuration prices vary. This price is for reference only. Contact us will have a very low price, please consult the specific price. Firs T furnace@gmail.com

capacity | model | KGPS power kw | Line voltage v | IF voltage v | Furnace structure | Price ¥ (yuan) |

100 KG intermediate frequency melting furnace | SDBLR - 1 00 kw | 100 kw KGPS | 3×380v | 750v | Aluminum furnace shell | Total price: ¥ 40000 Yuan |

250 KG intermediate frequency melting furnace | SDBLR - 2 00 kw | 200 kw KGPS | 3×380v | 750v | Aluminum furnace shell | Total price: ¥ 70800 Yuan |

2 50 KG parallel intermediate frequency melting furnace | SDBLBR - 2 00 kw | 400kw parallel KGPS | 3×380v | 750v | Aluminum furnace shell | Total price: ¥ 70800 Yuan |

2 50 KG series intermediate frequency melting furnace | SDBLCR - 2 00 kw | 400kw series KGPS | 3×380v | 1500v | Aluminum furnace shell | Total price: ¥ 90800 Yuan |

500 KG intermediate frequency melting furnace | SDBLR - 4 00 kw | 400kw KGPS | 3×380v | 1500v | Aluminum furnace shell | Total price: ¥ 131800 Yuan |

500 KG parallel intermediate frequency melting furnace | SDBLBR - 4 00 kw | 400kw parallel KGPS | 3×380v | 1500v | Aluminum furnace shell | Total price: ¥ 131800 Yuan |

500 KG series intermediate frequency melting furnace | SDBLCR - 4 00 kw | 400kw series KGPS | 3×380v | 1500v | Aluminum furnace shell | Total price: ¥ 151800 yuan |

0.75T intermediate frequency melting furnace | SDBLR - 5 00 kw | 5 00kw KGPS | 3×380v | 1500v | Aluminum furnace shell | Total price: ¥ 150000 Yuan |

0.75T parallel intermediate frequency melting furnace | SDBLBR - 5 00 kw | 5 00kw parallel KGPS | 3×380v | 1500v | Aluminum furnace shell | Total price: ¥ 150000 Yuan |

0.75T series connected intermediate frequency melting furnace | SDBLCR - 5 00 kw | 5 00kw series with KGPS | 3×380v | 1500v | Aluminum furnace shell | Total price: ¥ 188000 Yuan |

1 T intermediate frequency melting furnace | SDBLR - 8 00 kw | 8 00kw KGPS | 3×380v | 1500v | Steel shell body | Total price: ¥ 235000 Yuan |

1 T parallel intermediate frequency melting furnace | SDBLBR - 8 00 kw | 8 00kw parallel KGPS | 3×660v | 2500v | Steel shell body | Total price: ¥ 235000 Yuan |

1 T series intermediate frequency melting furnace | SDBLCR - 8 00 kw | 8 00kw series with KGPS | 3×660v | 2500v | Steel shell body | Total price: ¥ 275000 Yuan |

1.5 T intermediate frequency melting furnace | SDBLR - 12 00 kw | 120 0kw KGPS | 3×660v | 2500v | Aluminum furnace shell | Total price: ¥ 305000 Yuan |

1.5 T parallel intermediate frequency melting furnace | SDBLBR - 12 00 kw | 120 0kw parallel KGPS | 3×660v | 2500v | Steel shell body | Total price: ¥ 305000 Yuan |

1.5 T series intermediate frequency melting furnace | SDBLCR - 12 00 kw | 120 0kw series KGPS | 3×660v | 2500v | Steel shell body | Total price: ¥ 335000 Yuan |

2 T intermediate frequency melting furnace | SDBLR - 16 00 kw | 1600 kw KGPS | 3×660v | 2500v | Steel shell body | Total price: ¥ 369000 yuan |

2 T parallel intermediate frequency melting furnace | SDBLBR - 16 00 kw | 1600 kw parallel KGPS | 3×660v | 2500v | Steel shell body | Total price: ¥ 369000 yuan |

2 T series intermediate frequency melting furnace | SDBLCR - 16 00 kw | 1600 kw series KGPS | 3×660v | 2500v | Steel shell body | Total price: ¥ 429000 yuan |

3 T intermediate frequency melting furnace | SDBLR - 20 00 kw | 2000 kw KGPS | 3×660v | 2500v | Steel shell body | Total price: ¥ 459000 yuan |

3 T parallel intermediate frequency melting furnace | SDBLBR - 20 00 kw | 2000 kw parallel KGPS | 3×750v | 3200v | Steel shell body | Total price: ¥ 459000 yuan |

3 T series intermediate frequency melting furnace | SDBLCR - 20 00 kw | 2000 kw series KGPS | 6×750v | 3200v | Steel shell body | Total price: ¥ 499000 Yuan |

5 T intermediate frequency melting furnace | SDBLR - 30 00 kw | 3000kw KGPS | 6×750v | 3200v | Steel shell body | Total price: ¥ 1271,000 |

5 T parallel intermediate frequency melting furnace | SDBLBR - 30 00 kw | 3000 kw parallel KGPS | 6×750v | 3200v | Steel shell body | Total price: ¥ 1271,000 |

5 T series intermediate frequency melting furnace | SDBLCR - 30 00 kw | 30 00kw series KGPS | 6×750v | 3200v | Steel shell body | Total price: ¥ 1516,000 |

What is the difference between the aluminum shell intermediate frequency melting furnace and the steel shell intermediate frequency melting furnace ?

According to the type of furnace body: aluminum shell furnace and steel shell furnace. The aluminum shell furnace is a traditional furnace body. It is made of a thick aluminum alloy shell and is equipped with a reducer to pour molten iron. It is cheap and suitable forsmall furnaces of 0.5 tons and below. The shell of the steel shell is made of thick steel structure. The yoke is shielded from the magnetic field and leaks. It is safe and reliable. It is suitable for 1T and above furnace type.

The intermediate frequency melting furnace often adopts the following four configurations :

Each of the four configuration schemes has its own advantages and disadvantages. It is usually necessary to select the specific configuration method according to the casting process requirements of the equipment demand side, the on-site power conditions, the production target and the development scale to meet the requirements of efficient, safe and stable use of the equipment. Easy to flexibly adjust the process or scale expansion.

Scheme a single power supply;

Scheme second single power supply (series resonance) a tow two ways;

Scheme three pairs of power (parallel resonant) dual power supply;

Program four large and small power supply + double power supply switch turned furnace.;

How to save electricity in the intermediate frequency melting furnace? ?

1. Considering from the power supply: one is thyristor rectification, inverter. The power factor of the six-pulse rectification is low and the interference is large, and the power consumption is large. It would be better to use twelve veins.

2. Another type of power supply is a series intermediate frequency melting furnace , which is divided into 6- pulse and 12- pulse rectifiers. Generally, a 1- ton furnace adopts 12- pulse rectification, which has high power factor and saves electricity.

3. From the furnace: aluminum shell and steel shell, aluminum shell without magnetic heat, large heat, power consumption. The steel shell must have magnetic enthalpy, and the magnetic circuit has sequential power saving .

4. Before the molten steel in the furnace is full, the oven must be such that the furnace is in a full state, the compacted material, the greater the output power of the power, the faster the volume reduction, while repeatedly add materials, so they can quickly fall into the molten pool, the material can not be Suspended to prevent the molten steel below from boiling and causing the furnace to wear.

What is the difference between a high frequency melting furnace and an intermediate frequency melting furnace ?

The high-frequency melting furnace is suitable for melting gold, silver, copper and other alloys. The higher the power, the faster the melting speed, the temperature is up to 1800 °C , the high-frequency melting furnace is economical and practical, the melting is efficient, and the melting is fast . Current frequency is 100 ~ 500 kHz (kiloher), suitable for melting 1-5 KG precious metals, fast, cheap, small size, small footprint .

The intermediate frequency melting furnace includes a 0.25T-10T intermediate frequency melting furnace, which is widely used for the melting of non-ferrous metals, mainly used in the melting of ferrous metals such as molten steel, alloy steel, special steel, cast iron, and non-ferrous materials such as stainless steel and zinc . The current frequency is between 500 and 10000 Hz (Hertz), melting 5KG-60T various metals, featuring fast speed and high efficiency .

The main factors leading to the accident of the intermediate frequency melting furnace ?

The causes of most intermediate frequency melting furnace accidents in metallurgical plants are:

1 . The presence of moist materials in the charge causes a steam explosion.

2 . Temperature sampling or lack of operating skills when adding alloys, causing splashes of molten metal.

3 . Injecting large metal materials into the furnace causes the molten iron to splash.

4 . Unreasonable feeding system leads to bridging.

5 . Failure to escape outside the safety line resulted in injury.

6 . Contact with the power conductor, safety interlock control failure or contact with incompletely discharged capacitors, etc., resulting in shock or death.

7 . Lack of proper safety training.

Steel shell intermediate frequency melting furnace yoke structure

A , the yoke is made of WISCO's Q140 with oriented cold-rolled thickness of 0.3mm high-quality silicon steel sheet, and clamped on both sides with stainless steel plate. Optimized by microcomputer design, precision production, the contoured arc surface structure is consistent with the outer diameter of the coil.The yoke (induction coil) covering an area of more than 70%, the yoke fixing method: the yoke close to the induction coil, with high temperature high pressure between the insulating cushion, with 5 out of M24 captive jacking screw yoke On the back of the stainless steel plate.

B. The inside of the yoke stainless steel clamping plate is equipped with a specially designed water-cooled radiator. When the electric furnace is in operation, the yoke temperature is kept at normal temperature to prevent the yoke temperature from rising and deformation, thereby strengthening the support of the induction coil and improving The overall strength of the furnace.

Intermediate frequency melting furnace induction coil (ie sensor) structure advantages

A. The induction coil is made of extruded rectangular copper tube with the grade T2 (purity of 99.9% electrolytic copper) and wall thickness ≥5mm . It is wound on a special mold, which not only ensures the rigidity of the coil, but also has the largest conductive section. .

According to the ISO431-1981 standard, the coil material is selected to have the smallest copper loss and the highest electromagnetic conversion efficiency.

The induction coil is made of high temperature resistant and high pressure resistant insulating varnish. It is dip coated and vacuum dried. It is sprayed by blasting and then sprayed with porcelain. After cleaning, the insulating varnish has strong adhesion, long service life, high insulation and insulation grade. Reach level H. The induction coil is subjected to a 12kg/cm2 water pressure withstand voltage test for 36 hours and a 7000V withstand voltage test before leaving the factory . There will be no leakage.

B. The upper and lower parts of the induction coil are not only provided with stainless steel water cooling rings to ensure uniform heating of the furnace lining. Moreover, a Faraday short-circuit ring is provided to fully absorb the leakage flux at the upper and lower ends to prevent the furnace body from heating.The inductor is connected to a large-section water-cooled cable in the form of a side lead-out cable. The coil pressing device is pulled down on the stainless steel rod, which is easy to assemble and disassemble, and it is convenient to replace the coil.

PREV:No More Articles.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved