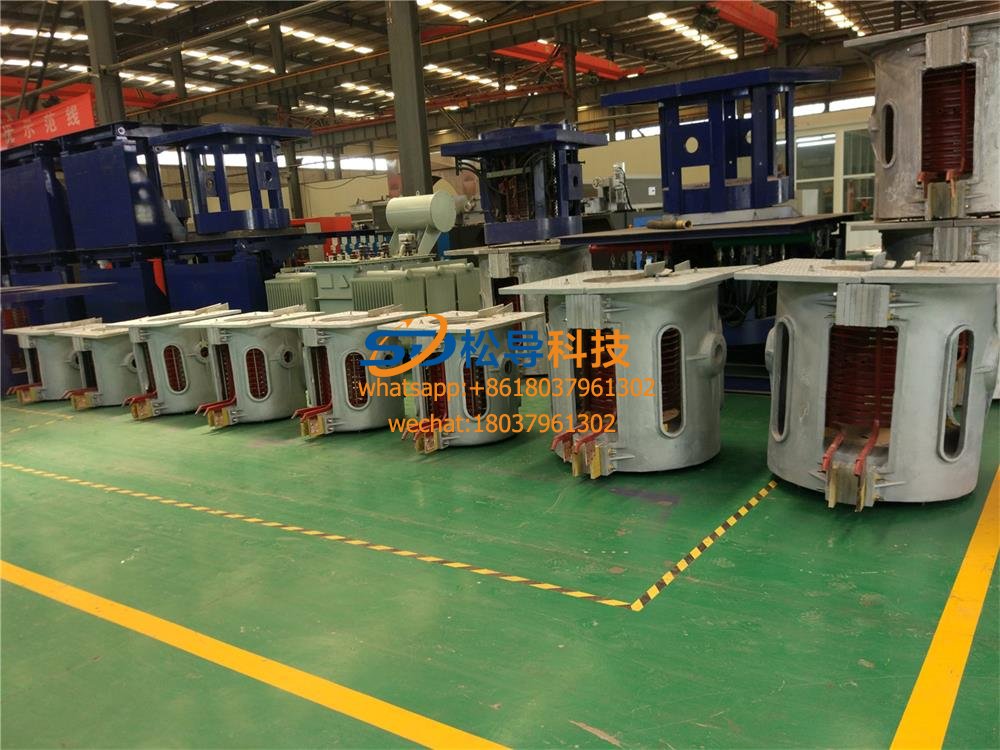

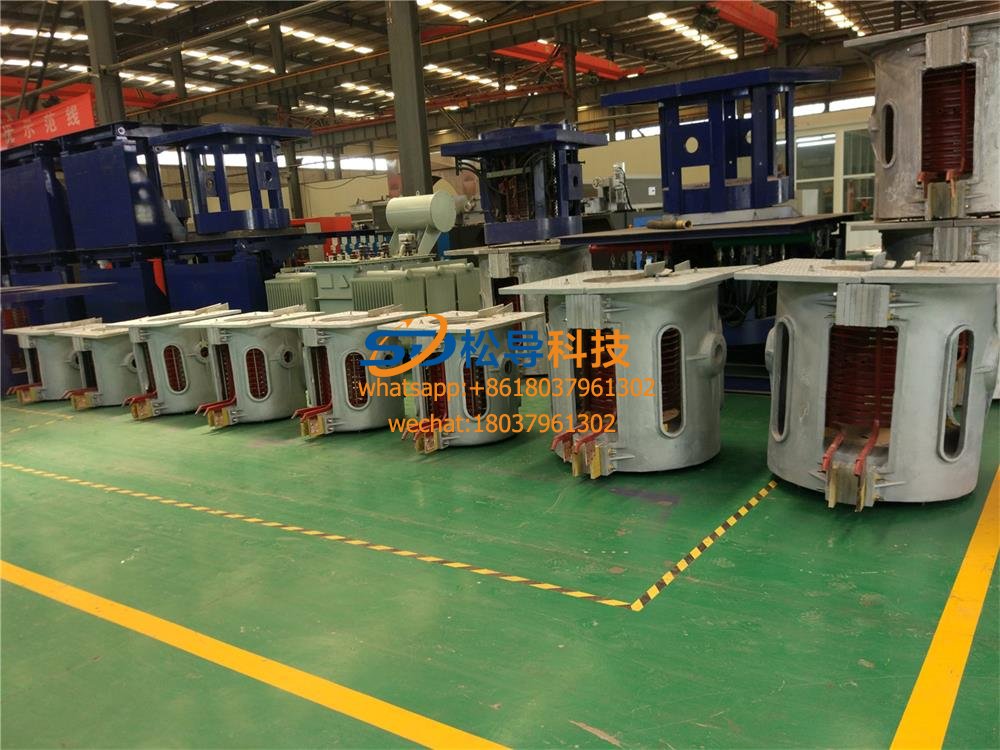

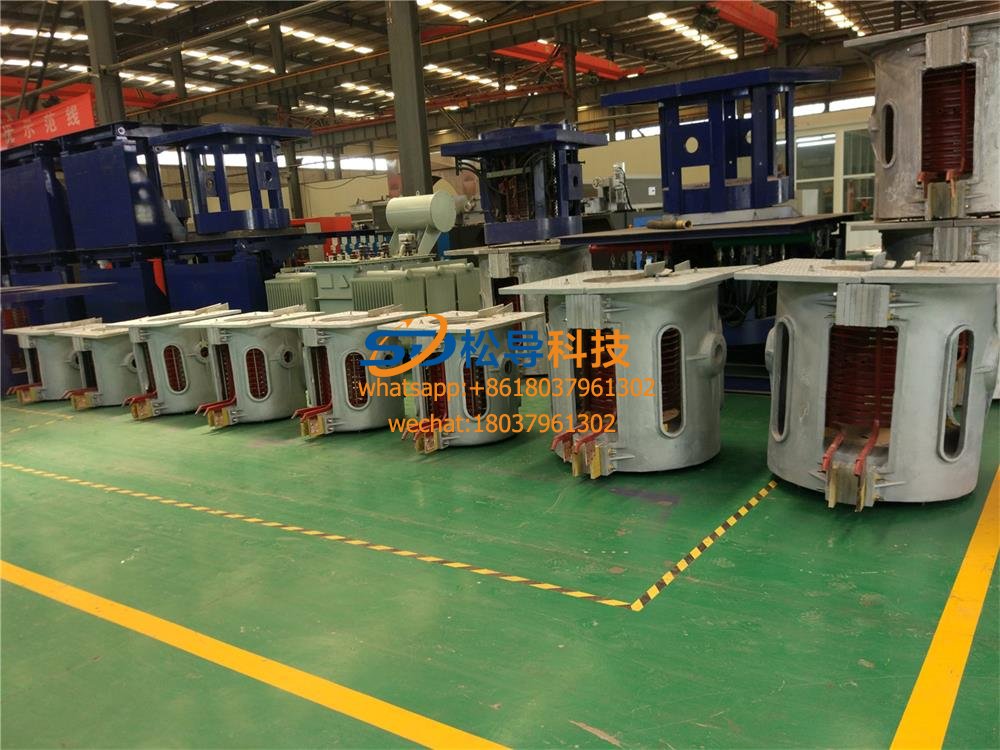

5T intermediate frequency melting furnace

5T intermediate frequency melting furnace 3T intermediate frequency melting furnace

3T intermediate frequency melting furnace 2T intermediate frequency melting furnace

2T intermediate frequency melting furnace 1T intermediate frequency melting furnace

1T intermediate frequency melting furnace Steel shell intermediate frequency melting furnace

Steel shell intermediate frequency melting furnace Aluminium Shell Intermediate Frequency Melting Furnace

Aluminium Shell Intermediate Frequency Melting Furnace intermediate frequency melting furnace

intermediate frequency melting furnace 0.75T Intermediate Frequency Melting Furnace

0.75T Intermediate Frequency Melting Furnace 0.5T Intermediate Frequency Melting Furnace

0.5T Intermediate Frequency Melting Furnace 250kg medium frequency melting furnace

250kg medium frequency melting furnace1. The aluminum shell intermediate frequency melting furnace is mainly composed of four parts :

1 , power and electrical parts: parallel inverter intermediate frequency power supply or series inverter intermediate frequency power supply

2 , the furnace part: aluminum shell, tilting furnace reducer , induction coil.

3 , transmission: mechanical reducer .

4 , water cooling system: closed loop cooling tower

The aluminum melting furnace IF power level selection, aluminum melting furnace sized for intermediate frequency selection method of selecting the intermediate frequency aluminum melting furnace power consumption.

model | unit | GW0.1-100/2.5 | GW0.25- 200 /1 | GW0.5- 400 /1 | GW1- 80 0/1 | GW1.5- 1200 /1 | GW 2 - 1 6 00 /1 | GW5- 3 000/0.5 |

Capacity selection | T | 0.1 | 0.25 | 0.5 | 1 | 1.5 | 3 | 5 |

Rated temperature | °C | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 |

IF power | Kw | 100 | 200 | 400 | 800 | 1200 | 1600 | 2000 |

IF voltage | V | 750 | 750 | 1500 | 1300 | 1300 | 2000 | 2500 |

IF frequency | KHz | 2.5 | 1 | 1 | 1 | 1 | 1 | 0.5 |

Power consumption selection | Kwh/t | 830 | 700 | 650 | 600 | 600 | 550 | 550 |

Flip type | Reducer | 231 reducer | 231 reducer | 431 reducer | 431 reducer | 531 reducer | 631 reducer | 731 reducer |

Transformer selection | KVA | 100 | 200 | 500 | 1000 | 1500 | 1600 | 3150 |

Water cooling tower selection | ZXZ | ZXZ- 10T | ZXZ- 20T | ZXZ- 40T | ZXZ- 80T | ZXZ- 140T | ZXZ- 160T | ZXZ- 240T |

The price of aluminum shell intermediate frequency melting furnace

IF the price of aluminum melting furnace is probably in the thousands of dollars each, there are thousands of dollars cheaper, you have hundreds of thousands of dollars. The price of aluminum shell intermediate frequency melting furnace is affected by many aspects, such as brand, category, specification, market and so on. It is necessary to understand and compare in many aspects before choosing to buy. The technical parameters of the aluminum shell intermediate frequency melting furnace are different, and the price is different, which is calculated according to the power of the intermediate frequency power supply and the volume of the furnace body. Different configuration prices vary. This price is for reference only. Contact us will have a very low price, please consult the specific price. First furnace@gmail.com

capacity | model | KGPS power kw | Line voltage v | IF voltage v | Furnace structure | Price ¥ (yuan) |

100 KG aluminum shell intermediate frequency melting furnace | SDBLR - 1 00 kw | 100 kw KGPS | 3×380v | 750v | Aluminum furnace shell | Total price: ¥ 40000 Yuan |

250 KG aluminum shell intermediate frequency melting furnace | SDBLR - 2 00 kw | 200 kw KGPS | 3×380v | 750v | Aluminum furnace shell | Total price: ¥ 70800 Yuan |

500 KG aluminum shell intermediate frequency melting furnace | SDBLR - 4 00 kw | 400kw KGPS | 3×380v | 1500v | Aluminum furnace shell | Total price: ¥ 131800 Yuan |

0.75T aluminum shell intermediate frequency melting furnace | SDBLR - 5 00 kw | 5 00kw KGPS | 3×380v | 1500v | Aluminum furnace shell | Total price: ¥ 120000 yuan |

1 T aluminum shell intermediate frequency melting furnace | SDBLR - 8 00 kw | 8 00kw KGPS | 3×380v | 1500v | Aluminum furnace shell | Total price: ¥ 150000 Yuan |

1.5 T aluminum shell intermediate frequency melting furnace | SDBLR - 12 00 kw | 120 0kw KGPS | 3×660v | 2500v | Aluminum furnace shell | Total price: ¥ 250000 Yuan |

2 T aluminum shell intermediate frequency melting furnace | SDBLR - 16 00 kw | 1600 kw KGPS | 3×660v | 2500v | Aluminum furnace shell | Total price: ¥ 360000 Yuan |

3 T aluminum shell intermediate frequency melting furnace | SDBLR - 20 00 kw | 2000 kw KGPS | 3×660v | 2500v | Aluminum furnace shell | Total price: ¥ 40000 Yuan |

5 T aluminum shell intermediate frequency melting furnace | SDBLR - 30 00 kw | 3000kw KGPS | 6×750v | 3200v | Aluminum furnace shell | Total price: ¥ 600000 |

What is the difference between the aluminum shell intermediate frequency melting furnace and the steel shell intermediate frequency melting furnace ?

According to the type of furnace body: aluminum shell furnace and steel shell furnace. The aluminum shell furnace is a traditional furnace body. It is made of a thick aluminum alloy shell and is equipped with a reducer to pour molten iron. It is cheap and suitable for small furnaces of 0.5tons and below. The shell of the steel shell is made of thick steel structure. The yoke is shielded from the magnetic field and leaks. It is safe and reliable. It is suitable for 1T and above furnace type.

Fifth, why do you choose aluminum alloy for the medium frequency melting furnace shell material?

The reason why the intermediate frequency melting furnace uses aluminum alloy material to make the outer shell of the furnace body is that the aluminum alloy does not generate heat in the electromagnetic environment. The outer casing of the intermediate frequency melting furnace can also be made of stainless steel and does not generate heat in an electromagnetic environment. If other magnetically permeable materials are used to make the outer casing of the intermediate frequency melting furnace , when the intermediate frequency melting furnace is working, the outer casing will heat up and turn red, and some joints that are not resistant to high temperature will be burned, resulting in equipment accidents.

The intermediate frequency melting furnace often adopts the following four configurations :

Each of the four configuration schemes has its own advantages and disadvantages. It is usually necessary to select the specific configuration method according to the casting process requirements of the equipment demand side, the on-site power conditions, the production target and the development scale to meet the requirements of efficient, safe and stable use of the equipment. Easy to flexibly adjust the process or scale expansion.

Scheme a single power supply;

Scheme second single power supply (series resonance) a tow two ways;

Scheme three pairs of power (parallel resonant) dual power supply;

Program four large and small power supply + double power supply switch turned furnace.;

How to save electricity in the intermediate frequency melting furnace? ?

1. Considering from the power supply: one is thyristor rectification, inverter. The power factor of the six-pulse rectification is low and the interference is large, and the power consumption is large. It would be better to use twelve veins.

2. Another type of power supply is a series intermediate frequency melting furnace , which is divided into 6- pulse and 12- pulse rectifiers. Generally, a 1- ton furnace adopts 12- pulse rectification, which has high power factor and saves electricity.

3. From the furnace: aluminum shell and steel shell, aluminum shell without magnetic heat, large heat, power consumption. The steel shell must have magnetic enthalpy, and the magnetic circuit has sequential power saving .

4. Before the molten steel in the furnace is full, the oven must be such that the furnace is in a full state, the compacted material, the greater the output power of the power, the faster the volume reduction, while repeatedly add materials, so they can quickly fall into the molten pool, the material can not be Suspended to prevent the molten steel below from boiling and causing the furnace to wear.

8. What is the difference between a high frequency melting furnace and an intermediate frequency melting furnace ?

The high-frequency melting furnace is suitable for melting gold, silver, copper and other alloys. The higher the power, the faster the melting speed, the temperature is up to 1800 °C , the high-frequency melting furnace is economical and practical, the melting is efficient, and the melting is fast . Current frequency is 100 ~ 500 kHz (kiloher), suitable for melting 1-5 KG precious metals, fast, cheap, small size, small footprint .

The intermediate frequency melting furnace includes a 0.25T-10T intermediate frequency melting furnace, which is widely used for the melting of non-ferrous metals, mainly used in the melting of ferrous metals such as molten steel, alloy steel, special steel, cast iron, and non-ferrous materials such as stainless steel and zinc . The current frequency is between 500 and 10000 Hz (Hertz), melting 5KG-60T various metals, featuring fast speed and high efficiency .

The main factors leading to the accident of the intermediate frequency melting furnace ?

The causes of most intermediate frequency melting furnace accidents in metallurgical plants are:

1 . The presence of moist materials in the charge causes a steam explosion.

2 . Temperature sampling or lack of operating skills when adding alloys, causing splashes of molten metal.

3 . Injecting large metal materials into the furnace causes the molten iron to splash.

4 . Unreasonable feeding system leads to bridging.

5 . Failure to escape outside the safety line resulted in injury.

6 . Contact with the power conductor, safety interlock control failure or contact with incompletely discharged capacitors, etc., resulting in shock or death.

7 . Lack of proper safety training.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved