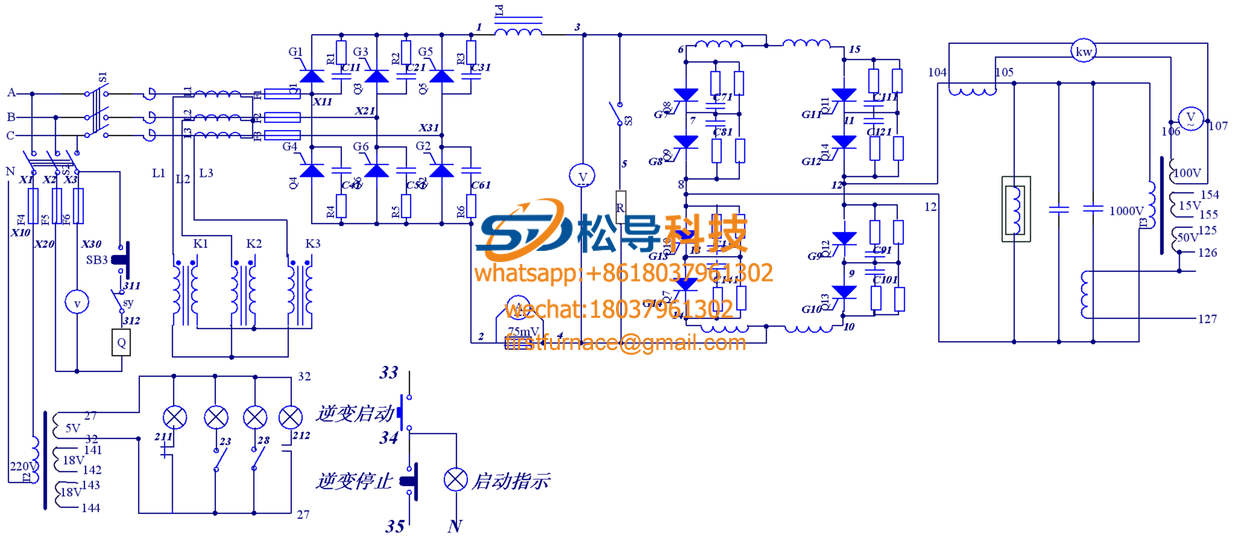

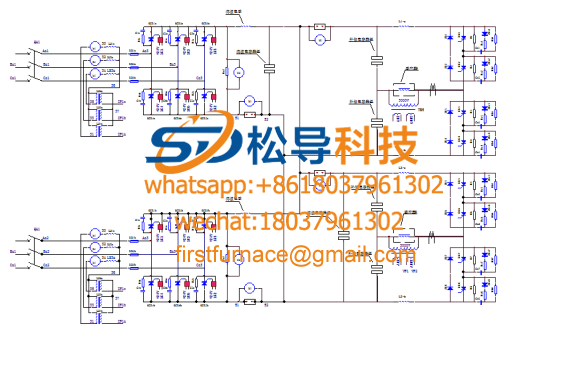

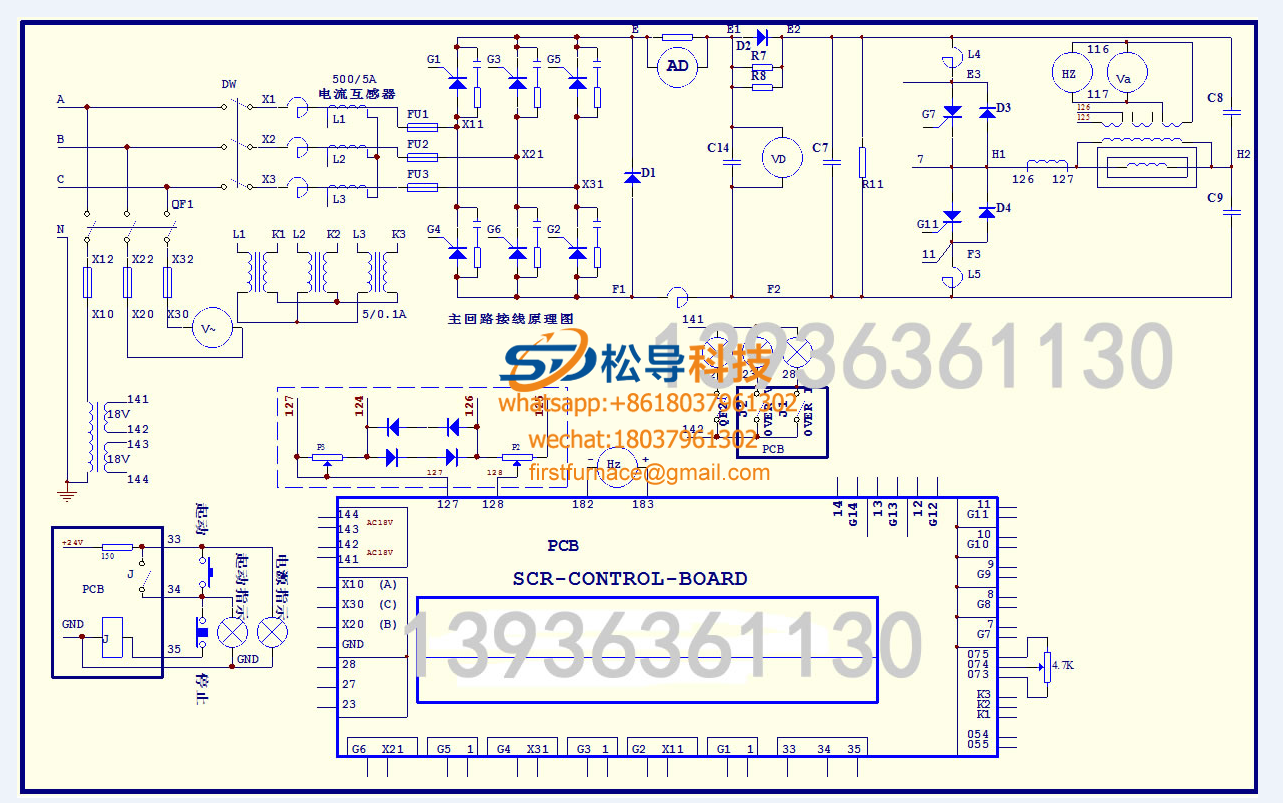

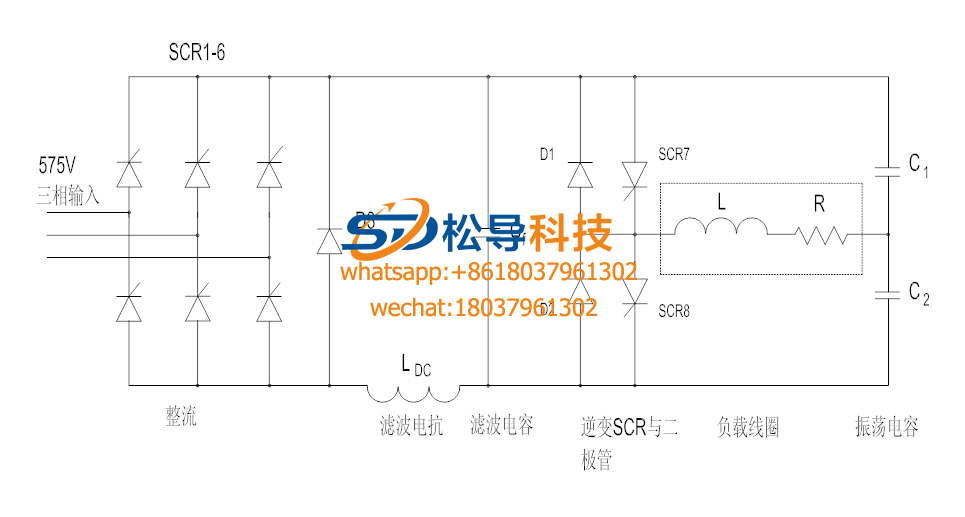

Intermediate frequency furnace main circuit schematic

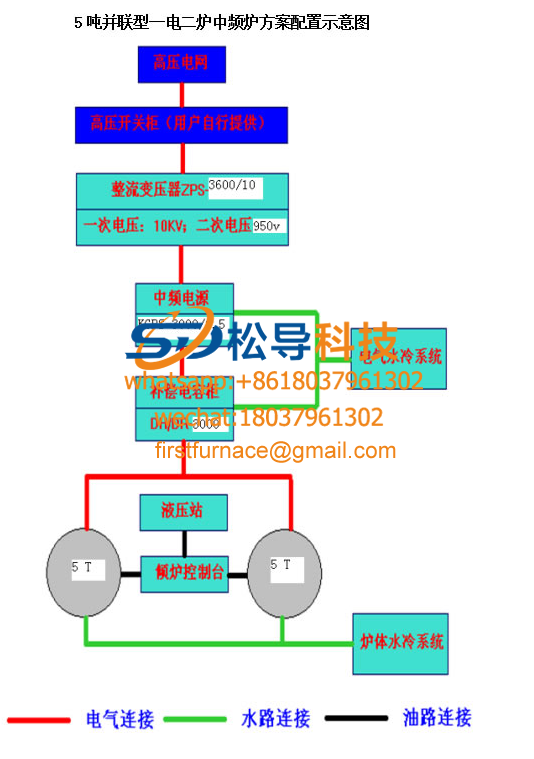

Intermediate frequency furnace main circuit schematic Schematic diagram of 5 tons of intermediate frequency melting

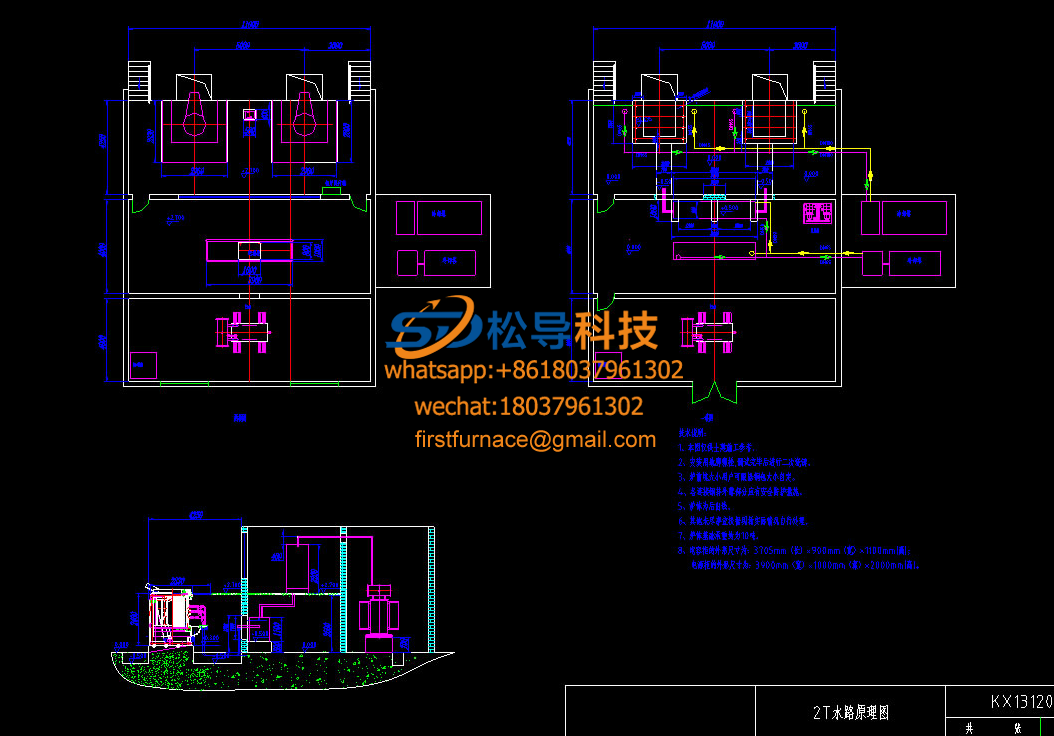

Schematic diagram of 5 tons of intermediate frequency melting 2 tons intermediate frequency furnace floor plan

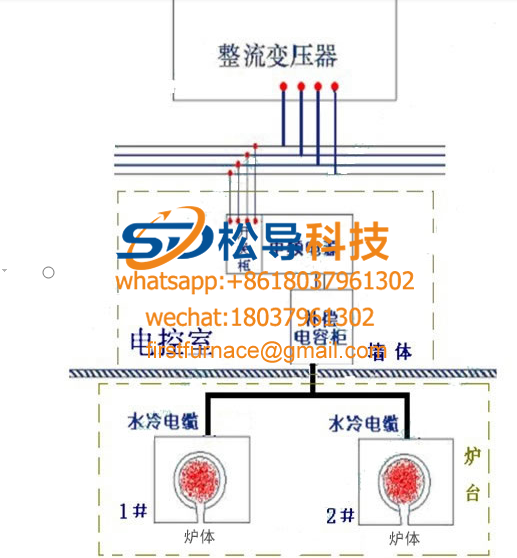

2 tons intermediate frequency furnace floor plan Technical Drawing of Simple Layout of Intermediate Frequency

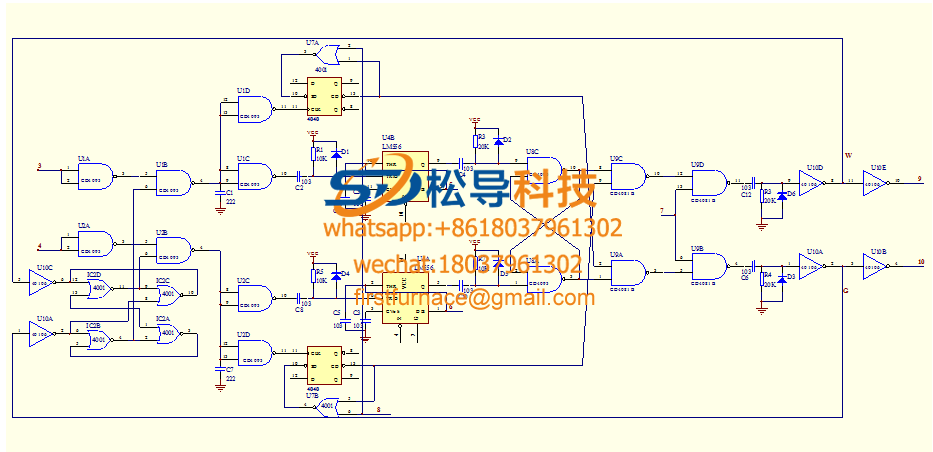

Technical Drawing of Simple Layout of Intermediate Frequency  Series intermediate frequency furnace triggering electrical s

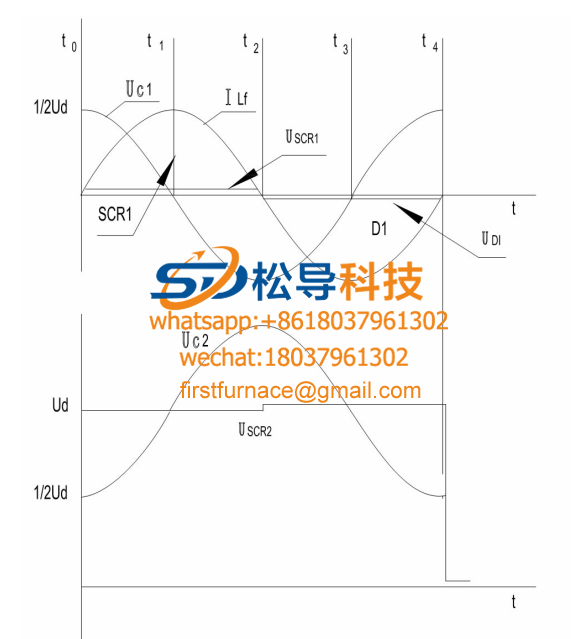

Series intermediate frequency furnace triggering electrical s Series intermediate frequency furnace inverter electrical wav

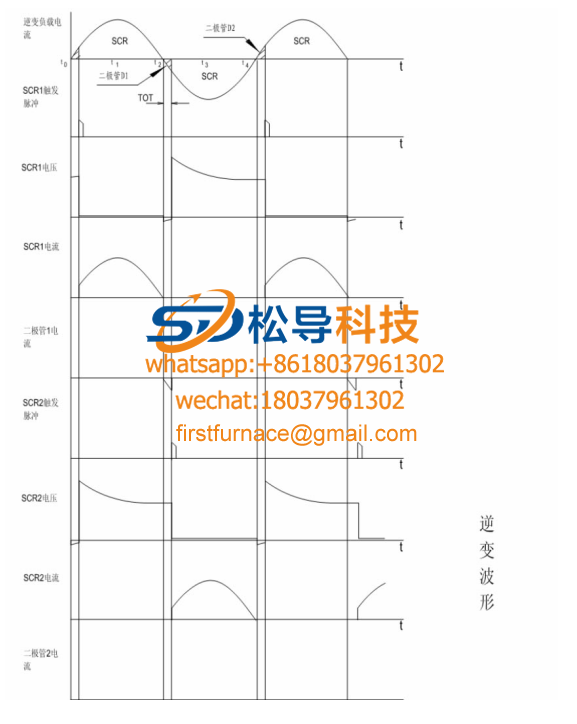

Series intermediate frequency furnace inverter electrical wav Series intermediate frequency furnace inverter circuit wavefo

Series intermediate frequency furnace inverter circuit wavefo 1T one belt two intermediate frequency furnace electrical sch

1T one belt two intermediate frequency furnace electrical sch 1 ton series intermediate frequency furnace main circuit draw

1 ton series intermediate frequency furnace main circuit draw 2T one belt two intermediate frequency furnace installation l

2T one belt two intermediate frequency furnace installation lThe main purpose of 1 T intermediate frequency furnace

1 T intermediate frequency furnace is mainly applied to steel, iron, copper, aluminum and alloys, having a high melting efficiency, energy-saving effect, a uniform metal composition, burning small, quick temperature rise, easy to control temperature, etc., suitable for all melting metals.

1 T intermediate frequency furnace composition:

800kw intermediate frequency power supply - steel shell furnace body - water cooled cable - remote console - ZXZ-80 T closed loop cooling tower.

1 T intermediate frequency furnace price summary table

The price of the 1 T intermediate frequency furnace is calculated according to the power of the intermediate frequency power supply and the volume of the furnace body. Different configuration prices vary. This price is for reference only. Contact us will have a very low price, please consult the specific price. FirsT furnace@gmail.com

Device name | Quantity | Total price (yuan) | Delivery time |

1T parallel intermediate frequency furnace | 1 set | ¥ 235000 Yuan | 30 days |

1T series intermediate frequency furnace | 1 set | ¥ 275000 Yuan | 30 days |

1T parallel intermediate frequency furnace item price

Serial number | Item name | Specification model | unit | Quantity | unit price | Total (yuan) |

1 | Parallel intermediate frequency power supply | KGPS- 800kw / 1 T | station | 1 | 140000 | 140000 yuan |

2 | Steel shell body | GW- 1 T | station | 1 | 80000 | 80000 |

3 | Water cooled cable | LHSD- 40 0 square | root | 2 | 3000 | 8000 |

4 | Leakage alarm system | LB T -1 | set | 1 | 5000 | 5000 |

5 | Remote console | H T -YK | station | 1 | 4 000 | 4 000 |

Total price: ¥ 235000 | ||||||

1T series intermediate frequency furnace item price

Serial number | Item name | Specification model | unit | Quantity | unit price | Total (yuan) |

1 | Series intermediate frequency power supply | KGPS- 800kw / 1 T | station | 1 | 180000 | 180000 |

2 | Steel shell body | GW- 1 T | station | 1 | 80000 | 80000 |

3 | Water cooled cable | LHSD- 40 0 square | root | 2 | 3000 | 8000 |

4 | Leakage alarm system | LB T -1 | set | 1 | 5000 | 5000 |

5 | Remote console | H T -YK | station | 1 | 4 000 | 4 000 |

Total price: ¥ 275000 | ||||||

1 T intermediate frequency furnace power supply , tonnage , power consumption selection method .

1 T intermediate frequency furnace model: GW T -1 T / 800 KW | 6- pulse rectifier power supply | 12- pulse rectifier power supply Aluminum shell body Advanced configuration | 12- pulse rectifier power supply |

Equipment rated power | 800 kw | 800 kw | 800 kw |

Phase voltage | 3*660V | 6*660V | 6*660V |

Electric furnace rated voltage | 3000V | 3000V | 3000V |

Melting rate | About 1.1 T / H | About 1.2 T / H | About 1.3 T / H |

Rated Capacity | 1 T | 1 T | 1 T |

Rated temperature | 1800 ° C | 1800 ° C | 1800 ° C |

Intermediate frequency power rectifier | 3- phase 6- pulse rectification | 6- phase 12- pulse rectification | 6- phase 12- pulse rectification |

DC | 680A | 680A | 680A |

Alternating current | 555 A | 555 A | 555 A |

Power factor | ≥0.95 | ≥0.95 | ≥0.95 |

Tilting method: | Optional gearbox or hydraulic | Optional gearbox or hydraulic | Optional gearbox or hydraulic |

With power supply specifications | KGPS-1/ 800 | KGPS-1/ 800 | KGPS-1/ 800 |

Fast intermediate frequency power supply | One set (with filter capacitor inside) ) 6- pulse intermediate frequency power supply | One set (with filter capacitor inside) 12- pulse intermediate frequency power supply | One set (with filter capacitor inside) 12- pulse intermediate frequency power supply |

Compensation capacitor cabinet | set | set | set |

stove | Aluminum shell furnace | Aluminum shell furnace | Steel shell mechanism furnace (including yoke) |

Reducer | One | One | Hydraulic |

Water cooled cable | Two | Two | Two |

Decidua | One | One | One |

1 T intermediate frequency furnace circuit diagram :

1 T intermediate frequency furnace advantages:

1 T intermediate frequency furnace advantages:

1. Due to the characteristics of the resonant circuit, the variable frequency power supply with parallel resonance has good protection when the circuit is short-circuited. Because the reactor device with buffer function installed in the intermediate circuit can effectively suppress the rapid rise of current, it can be reliably turned off when the circuit fails.

2 , resonant frequency conversion environmental source and inverter side loss is very small (because the large current only works in the resonant circuit) and accurate coil voltage control (to make full use of the highest power of the capacitor group)

3 , the technology is mature, the performance of the whole machine is stable and reliable, and has a competitive advantage.

4 , easy to operate, easy to use

5 , the maintenance speed is fast, the maintenance difficulty and maintenance costs are low!

6 , the price is relatively cheap.

What are the choices of the seven, 1 T intermediate frequency furnace structure ?

Furnace 1 T IF consists of four portion of the furnace shell, an induction coil, lining, etc. gearbox tilting furnace furnace structure wherein selecting two ways: In the structure of aluminum alloy reducer turndown mode melting furnace supply Commonly known as aluminum shell furnace. The induction melting furnace of the steel structure with the hydraulic cylinder as the tilting furnace is commonly called the steel shell furnace. The steel shell furnace is a steel structure , and the aluminum shell furnace shell material is an aluminum alloy . 1 T medium frequency furnace because of its medium size , aluminum shell furnace and steel shell furnace have customers to choose, domestic steel shell furnace mostly.

What information does the customer need to provide to the supplier before purchasing the 1 T intermediate frequency furnace ?

1. 1 T medium frequency furnace should have layout space, need to provide the area and layout of the plant

2. The customer needs to provide the capacity of the transformer, the magnitude of the incoming line voltage, and the frequency of the incoming line voltage.

3. The medium frequency induction furnace needs water cooling equipment, and the 1 T intermediate frequency furnace configuration contains water cooling equipment.

4. The structure of the medium frequency induction melting furnace has a steel shell furnace body and an aluminum shell furnace body, and the customer needs to specify the furnace body structure.

5. The power supply of the medium frequency induction melting furnace is the intermediate frequency power supply. The line structure of the intermediate frequency power supply is divided into the inverter parallel and the inverter series structure. The inverter series structure is energy-saving, the power factor is 0.98 , and the line is stable. The inverter parallel structure is a parallel type with a power factor of 0.92 , which requires the customer to specify the line structure.

How to reduce the power consumption of the 1 T intermediate frequency furnace ?

Properly increase the power supply. Accelerate the melting speed. Do not use hot metal in each furnace, as long as it is a little bit beneficial to the melting of the charge. Drain the metal material, try not to let it get stuck, can melt down smoothly, pay special attention to the low melting point specification of pig iron, etc. It should be arranged in the vicinity of the induction coil. The induced current is larger and melts faster, and the drop is fast, which is conducive to the formation of the molten pool. Further melting the entire charge. The bobbin-type charge should not be cut because its induced current is continuous, which is conducive to power improvement.

How to improve the melting speed of the 1 T intermediate frequency furnace?

1. Increase the power of the intermediate frequency induction melting furnace intermediate frequency power supply.

2. Choose a reasonable charge size and the correct feeding method.

3. Appropriate molten iron outlet temperature.

What should I pay attention to in the operation of the intermediate frequency furnace ?

The phase-frequency AC power is converted into DC power, and after the inverter circuit output is converted into a single-phase AC power, the metal is heat-treated according to the principle of electromagnetic induction. However, in order to ensure that the intermediate frequency furnace can operate efficiently, it is necessary to carry out safe operation. The following is a detailed description of how to carry out safe operation.

1 , precautions before opening the furnace

The intermediate frequency electric furnace must check the electrical equipment, the water cooling system, the inductor copper tube, etc. before the furnace is opened. Only when these several equipments are in good condition can the correct method of safe operation of the intermediate frequency furnace be analyzed.

IF forging and casting furnace is a thermal processing apparatus for the inverter unit of several parts, the furnace and furnace control other components of the furnace by three, to ensure the safety of the heat treatment, or prohibiting the opening of the furnace; specifically determining The person responsible for power transmission and opening, and the responsible person shall not leave the post without authorization. During the work, the external condition of the sensor and the cymbal must be supervised to prevent people from touching the sensor and cable after power transmission, which affects the normal operation of the intermediate frequency electric furnace. Work or a safety accident.

2 , precautions after opening the furnace

After the intermediate frequency furnace is opened, during the charging, the inside of the furnace should be inspected to avoid mixing with flammable and explosive materials. In order to prevent the occurrence of the capping phenomenon, it is strictly forbidden to directly add the cold material and the wet material in the molten steel, and after the molten liquid is filled to the upper portion, the bulk material should not be added ; in order to avoid the explosion accident, it is necessary to ensure the pouring place and the furnace. There is no water in the front pit, no obstacles . In the pouring, two people need to cooperate, and the remaining molten steel can only be dumped at the place where it is made, and cannot be dumped anywhere.

3 , precautions during maintenance

When maintaining the medium frequency electric furnace, the internal frequency generator room should be kept clean and the flammable and explosive materials should not be stacked. Repair the furnace with excessive melt loss in time, and avoid the incorporation of iron filings and iron oxide in the furnace to ensure the compaction of the crucible.

What are the main factors that cause the accident in the intermediate frequency furnace ?

The causes of the explosion of the intermediate frequency furnace are:

1 . The presence of moist materials in the charge causes a steam explosion.

2 . Temperature sampling or lack of operating skills when adding alloys, causing splashes of molten metal.

3 . Injecting large metal materials into the furnace causes the molten iron to splash.

4 . Unreasonable feeding system leads to bridging.

5 . Failure to escape outside the safety line resulted in injury.

6 . Contact with the power conductor, safety interlock control failure or contact with incompletely discharged capacitors, etc., resulting in shock or death.

7 . Lack of proper safety training.

The main points of medium frequency furnace steel

1 , the task of steel

The main raw material for melting is scrap steel and a part of pig iron. The purchased scrap has more rust, muddy sand and other dirt, and the content of sulfur and phosphorus in the steel is also high. The task of the steel is to smelt the raw materials of the above conditions into high-quality molten steel with low gas content, high inclusion content, qualified components and temperature. Specifically, the basic tasks of the steel are:

( 1 ) melting solid charge (cast iron, scrap, etc.);

( 2 ) making the elements such as silicon, manganese and carbon in the molten steel reach the specification components;

( 3 ) removing harmful elements such as sulfur and phosphorus and reducing their content below the specified limit;

( 4 ) removing gas and non-metallic inclusions in the molten steel to make the molten steel pure;

( 5 ) adding alloying elements (melted alloy steel) to meet the requirements;

( 6 ) The molten steel is superheated to a certain temperature to ensure the need for pouring;

( 7 ) In order to increase production and reduce costs, it is necessary to rapidly reduce steel;

( 8 ) Casting into a good casting.

2 , the method of steel

There are many methods for chemical steel, mainly including induction furnace steel, open hearth steel, and electric arc furnace steel.

Electric arc furnaces and induction furnaces commonly used in cast steel workshops. They have looser requirements on raw materials, higher quality of molten steel, and the steelmaking cycle is suitable for the characteristics of cast steel production. It is convenient to open and stop the furnace, and it is easy to coordinate with the progress of the process of molding and boxing. Organize production. In addition, the equipment for electric furnace steel is relatively simple, with less investment, and the infrastructure construction speed and capital recovery are fast.

In recent years, induction furnace steel has gradually developed. Induction furnace steel process is relatively simple, and the quality of molten steel can be guaranteed. Many factories use induction furnace steel to cast small castings, especially in investment casting foundries, and widely use induction furnaces to melt molten steel.

In the heavy machinery factory, flat furnace steel has been used so far. The capacity of the open hearth furnace is generally larger than that of the electric furnace. The flat steel can be used to produce a large amount of molten steel at one time, which is suitable for pouring large and complex heavy castings.However, the cycle of open hearth steel is long, and the time for producing a furnace steel generally takes more than six hours. The open hearth structure is large and complex, the output is low, and the quality of the molten steel is not as good as that of the electric furnace, so its development is greatly limited. In some countries, new open hearths are no longer built.

In recent decades, pure steel top-blown converters have been widely used in the steel industry to convert steel. This method of steelmaking is fast, high in productivity, and the quality of molten steel is also guaranteed. This type of furnace is more suitable for steel ingot production.

With the development of production and science and technology, new steelmaking methods for DC arc furnaces, vacuum induction furnaces and refining equipment outside the furnace have emerged, the quality of molten steel has been greatly improved, and the quality of castings has been greatly improved.

What are the factors that affect the energy consumption of the intermediate frequency furnace?

Factors that affect energy consumption intermediate frequency furnace mainly in the following four points:

1 , power supply

The frequency density configuration of the intermediate frequency furnace is high. The configuration is high, the melting speed is fast, and the energy saving effect is good. Whether the intermediate frequency furnace can maintain high power and continuously send power to the furnace will affect the energy consumption; the intermediate frequency furnace power supply line is disorderly, which will affect the power processing capacity, resulting in unstable power, low power conversion efficiency, and influence energy. Consumption.

2 , the melt

The cleanliness of the surface of the charge, such as 5 % impurities, will consume 5 % of the electrical energy to melt these impurities, and will affect the life of the lining; the appropriate length of the furnace block will affect the electrical efficiency and melting quality of the electric furnace, generally200 ~ 300mm block is suitable;

3 , refractory materials

The use of a suitable crucible can increase the melting rate, the quartz crucible is resistant to high temperatures, and is used with an intermediate frequency furnace. The metal material in the crucible generates heat by induction heating, which can reduce the heat transfer consumption.

4 , improper operation causes high energy consumption

The molten metal is overheated and the liquid is discharged from the furnace. Not only is it unsafe, it is also wrong in terms of energy consumption and melting process. Generally, the electric furnace sensor is divided into two parts. When the metal liquid level in the furnace is lower than half of the upper inductor, the upper inductor no longer has an induced current passing due to the resistance change, and all of the lower inductors are concentrated in the lower inductor to make the lower metal liquid. Overheating, flushing the furnace wall, the life of the lining drops sharply.

How to save power in the intermediate frequency furnace? ?

1. Under the premise of ensuring the reasonable operation of the workers, the rationality of the layout, and the overall layout of the electric furnace, we should minimize the space layout to shorten the overall connection line, which will reduce the loss of thermal power and save electricity.

2 , the material used should be as large as possible to ensure a smooth flow of current to prevent the copper row too small, causing the heat to take away part of the power.

3, to be diligent workers, and to continue feeding the auxiliary stirring steel, increase the speed of melting, saving power consumption

4 , the technical content of the intermediate frequency furnace, this point is not well determined by the manufacturers. Although the intermediate frequency furnace technology is relatively mature, each family still has its own certain advantages. Therefore, manufacturers are advised to choose large manufacturers to cooperate when purchasing electric furnaces. Make sure you save on power consumption.

Yoke IF furnace temperature is too high what is the reason?

The yoke redness is a common failure phenomenon in the operation of the intermediate frequency power supply. First check if there is any problem with the cooling water system, check whether the red yoke inlet and outlet water is normal, and whether the pipeline is aging or leaking. If it is normal, check the following aspects.

(1) The yoke of the intermediate frequency power supply is aging, and the interlayer insulating coating is severely corroded. For this, the silicon steel sheet can be opened for surface coating treatment.

(2) The yoke is adhered to the molten steel (iron filings), and the yoke can be polished to remove the adhered iron filings.

(3) Check the thickness of the bottom of the furnace. If the bottom of the furnace is too thick, it will cause the yoke to heat up and become red.

(4) The temperature of the circulating water inlet water is too high, and the water temperature inside the yoke circulation system is too high to generate gas. Since the gas cannot be discharged, the circulating water cannot circulate, causing the temperature to rise.

5 ) The circulating water pressure becomes smaller, or after the waterway is changed, the waterway becomes more or the water pipe becomes larger, and the water flow of the other circuits becomes larger, causing the yoke water flow to become smaller.

Is the IGBT intermediate frequency furnace really more energy efficient than the SCR intermediate frequency furnace?

Under the same conditions, the IGBT electric furnace saves 0.0976 % more energy than the SCR electric furnace , which is almost negligible.

IGBT is a new type of switching device, with fast switching speed, plus control signal conduction, eliminating control signal cut-off, convenient control, reduced conduction voltage and low power consumption. The maximum current of the IGBT is only 2 times the rated current, the impact resistance is poor. SCR is a traditional switching device with high control power and high impact resistance. Is the IGBT electric furnace really more energy efficient than the SCR electric furnace ? We can see whether the power is saved by the following calculation.

1 t The power of 500KW electric furnace, into the phase voltage 380V, IGBT electric power factor is 0.98, the DC current is 928A, the power consumed by the IGBT4 [1V (IGBT conduction voltage drop) X 928A/2] X 4=1856W=1.856KW ; SCR electric furnace has a power factor of 0.93 and DC current is 977A. The power consumed by SCR is: [1.2V ( SCR conduction voltage drop) X977A/2] X 4=2344W=2.344KW. It can be seen that the power consumed by the IGBT is 21 % lower than the power consumed by the SCR .

It is concluded that the IGBT electric furnace saves 21 % compared with the SCR electric furnace . It is wrong. We continue to calculate that the power consumed by the IGBT is 1.56KW/500KW=0.003712=0.3712% of the total power ; the power consumed by the SCR is the total power. The percentage is2.344KW/500KW=0.004688=0.4688%. It can be seen from the above calculation data that under the same conditions, the IGBT electric furnace saves 0.0976 % compared with the SCR electric furnace , which is almost negligible.

If other conditions are changed, the IGBT electric furnace adopts series inverter, and by increasing the intermediate frequency voltage to save electricity, that is another matter. SCR electric furnace can increase the intermediate frequency voltage by 2 times voltage. Since the withstand voltage and current of SCRare much higher than IGBT devices, SCR electric furnace can adopt high phase voltage and high intermediate frequency voltage. Therefore, SCR electric furnace is reasonable in design and expensive IGBT. Electric furnaces should be more energy efficient.

SCR electric furnace can use high phase voltage and high intermediate frequency voltage. Therefore, if the SCR electric furnace is designed reasonably, it is more energy-saving than the expensive IGB T electric furnace.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved