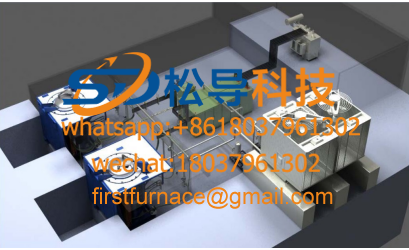

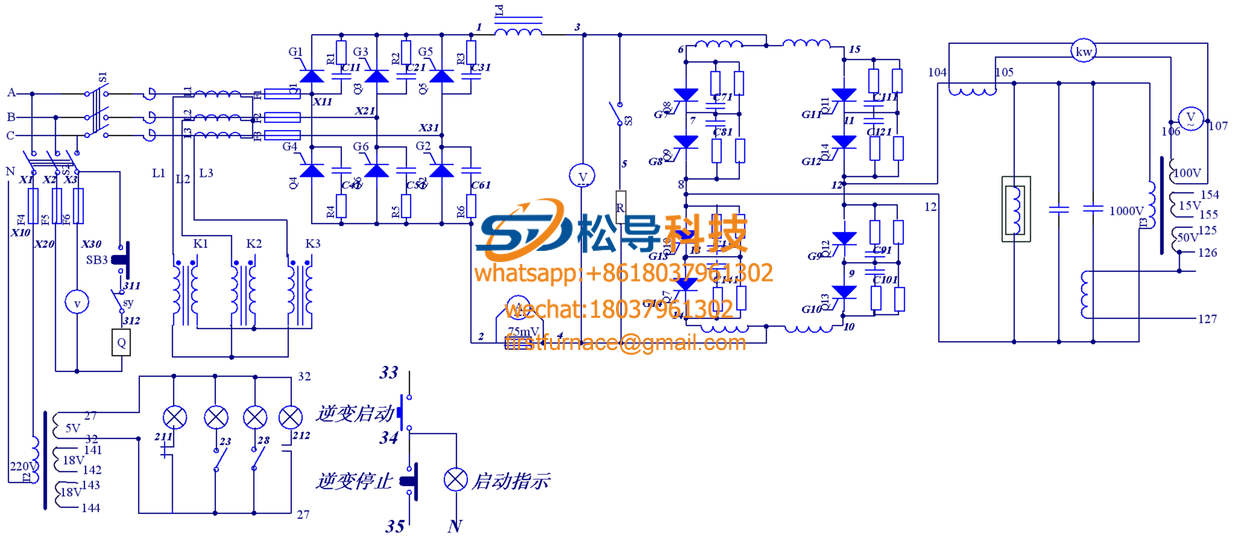

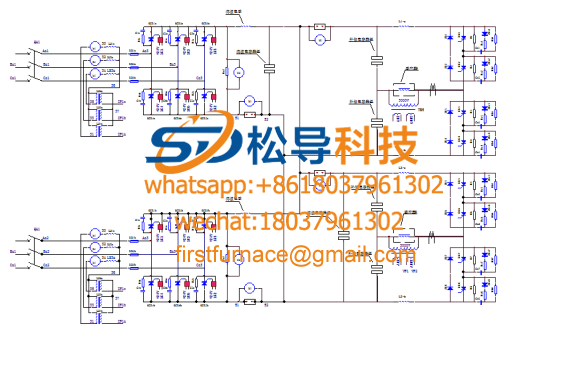

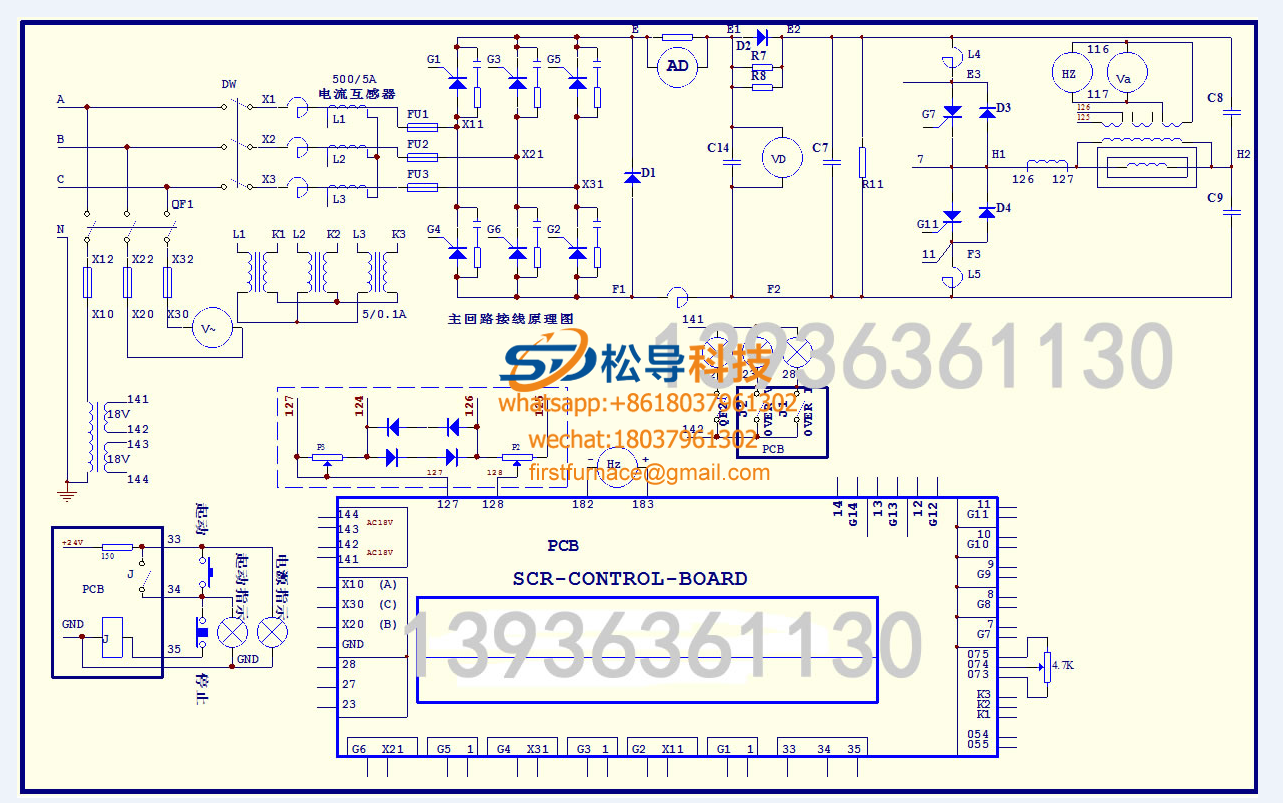

Intermediate frequency furnace main circuit schematic

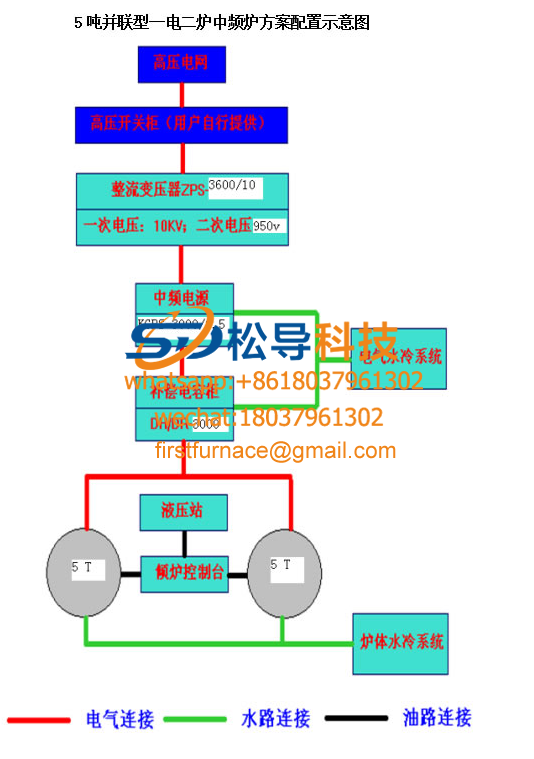

Intermediate frequency furnace main circuit schematic Schematic diagram of 5 tons of intermediate frequency melting

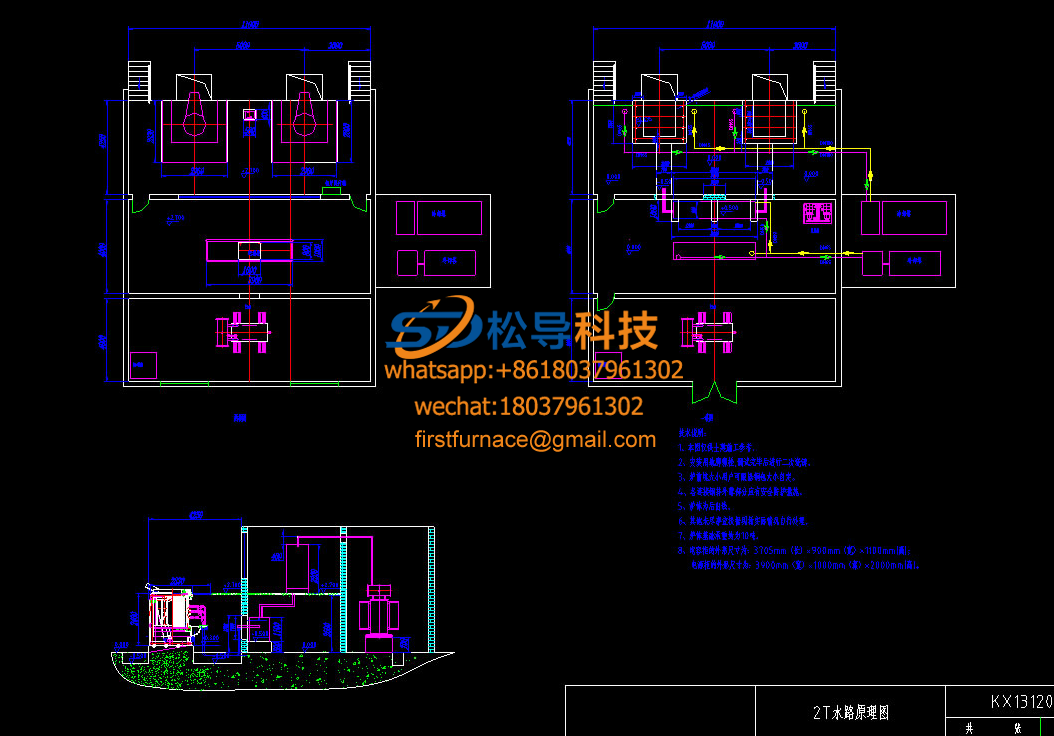

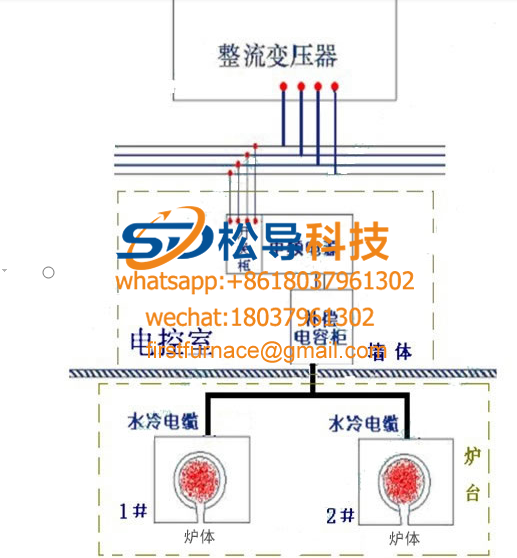

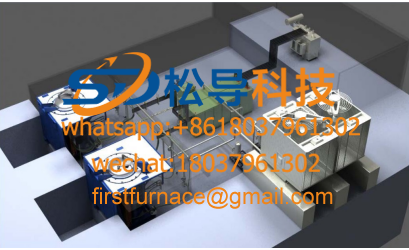

Schematic diagram of 5 tons of intermediate frequency melting 2 tons intermediate frequency furnace floor plan

2 tons intermediate frequency furnace floor plan Technical Drawing of Simple Layout of Intermediate Frequency

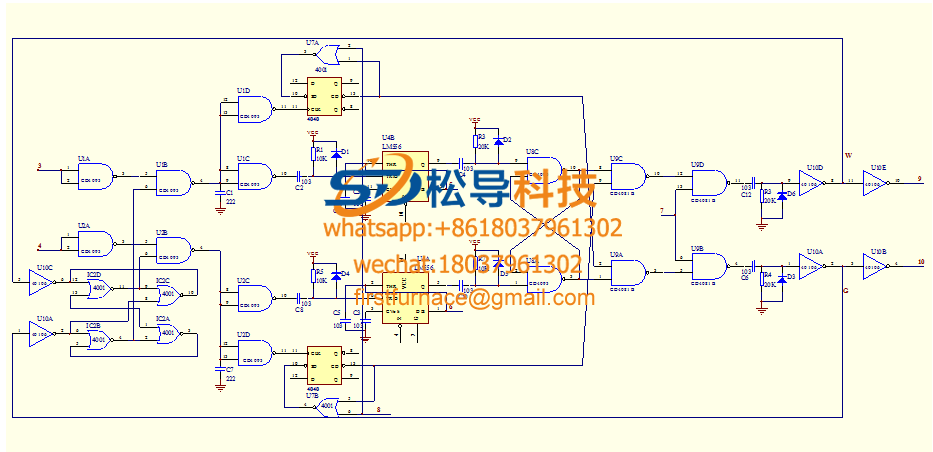

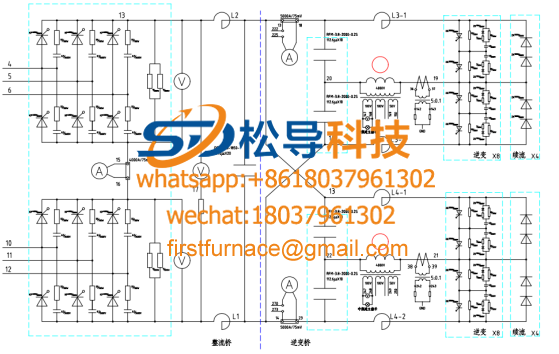

Technical Drawing of Simple Layout of Intermediate Frequency  Series intermediate frequency furnace triggering electrical s

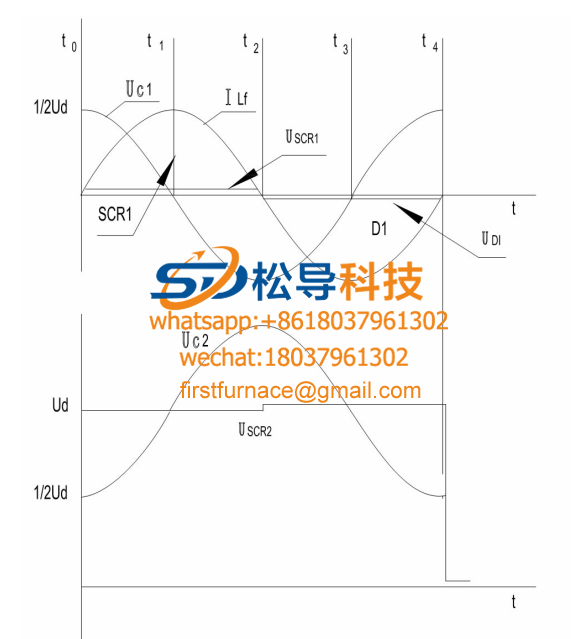

Series intermediate frequency furnace triggering electrical s Series intermediate frequency furnace inverter electrical wav

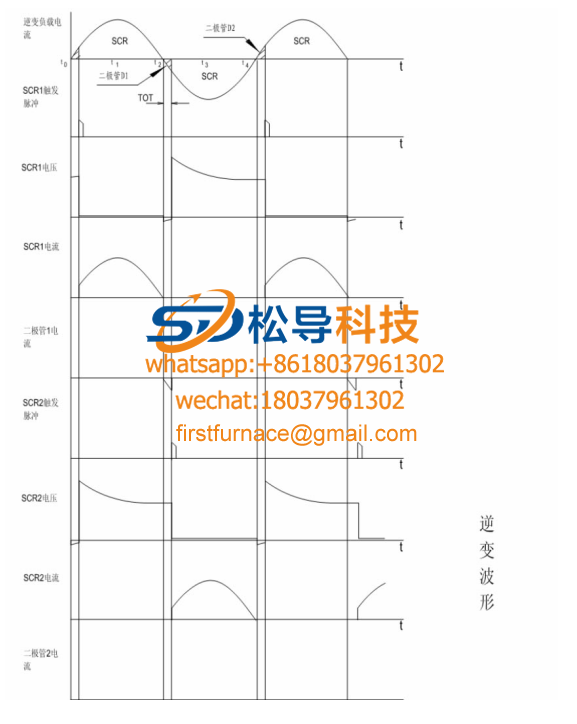

Series intermediate frequency furnace inverter electrical wav Series intermediate frequency furnace inverter circuit wavefo

Series intermediate frequency furnace inverter circuit wavefo 1T one belt two intermediate frequency furnace electrical sch

1T one belt two intermediate frequency furnace electrical sch 1 ton series intermediate frequency furnace main circuit draw

1 ton series intermediate frequency furnace main circuit draw 2T one belt two intermediate frequency furnace installation l

2T one belt two intermediate frequency furnace installation lI. Overview:One belt two intermediate frequency furnace a furnace with two can work simultaneously (commonly known as the one for two), a dual output power supply series resonance, respectively to the two electric power supply, the power supply may be in two IF using arbitrarily assigned between the furnace, amelting furnace, another set of furnace insulation, the two may be simultaneously melt furnace production, improved so greatly limits the production capacity.

Second, the basic composition of One belt two intermediate frequency furnace equipment

The device mainly comprises a series resonant dual output power supply, a steel shell or an aluminum shell furnace body, a closed loop cooling water system and the like.

Third, one of the three working modes of the two intermediate frequency furnace :

1, one furnace is melted and the other is spared

2, one furnace is melted and the other is simultaneously insulated

3, the two furnace bodies melt simultaneously

Four, one for two intermediate frequency furnace price summary table

The price of One belt two intermediate frequency furnaces is calculated according to the power of the intermediate frequency power supply and the volume of the furnace body. Different configuration prices vary. This price is for reference only. Contact us will have a very low price, please consult the specific price. Firstfurnace@gmail.com

One belt two intermediate frequency furnace power supply power capacity, the method of selecting power consumption and price:

name | model | Line voltage V | rated power | IF voltage V | Power consumption | Furnace structure | Price ¥ (yuan) |

6- pulse aluminum shell one for two intermediate frequency furnace | |||||||

1T One belt two intermediate frequency furnace | GWDT -1T/1200KW | 3*660V | 1200KW | 3 2 00v | 580 ±5% kW.h/t ( 1 55 0 ° C ) | Aluminum shell | Total: ¥ 280000 Yuan |

2T One belt two intermediate frequency furnace | GWDT -1T/1500KW | 3 *660V | 1 8 00KW | 3 2 00v | 580 ±5% kW.h/t ( 1 55 0 ° C ) | Aluminum shell | Total: ¥ 320000 Yuan |

3T One belt two intermediate frequency furnace | GWDT -1T/1500KW | 6*660V | 2 500KW | 3 6 00v | 580 ±5% kW.h/t ( 1 55 0 ° C ) | Aluminum shell | Total: ¥ 450000 Yuan |

5T One belt two intermediate frequency furnace | GWDT -2T /2000KW | 3*660V | 35 00KW | 3 6 00v | 580 ±5% kW.h/t ( 1 55 0 ° C ) | Aluminum shell | Total: ¥ 1350000 Yuan |

6- pulse steel shell 1 T One belt two intermediate frequency furnace | |||||||

1T One belt two intermediate frequency furnace | GWST -2T / 2400KW | 3*660V | 1200KW | 3 2 00v | 580 ±5% kW.h/t ( 1 55 0 ° C ) | Steel shell | Total: ¥ 400000 Yuan |

2T One belt two intermediate frequency furnace | GWST -2T / 2400KW | 3 *660V | 1 8 00KW | 3 2 00v | 580 ±5% kW.h/t ( 1 55 0 ° C ) | Steel shell | Total: ¥ 500000 Yuan |

3T One belt two intermediate frequency furnace | GWST -3T/3000KW | 6*660V | 2 500KW | 3 6 00v | 580 ±5% kW.h/t ( 1 55 0 ° C ) | Steel shell | Total: ¥ 650000 Yuan |

5T One belt two intermediate frequency furnace | GWST -3T/4000KW | 3*660V | 35 00KW | 3 6 00v | 580 ±5% kW.h/t ( 1 55 0 ° C ) | Steel shell | Total: ¥ 145000 Yuan |

12- pulse steel shell 1 T One belt two intermediate frequency furnace | |||||||

1T One belt two intermediate frequency furnace | GWST -2T / 2400KW | 6* 660 V | 1200KW | 3 2 00v | 580 ±5% kW.h/t ( 1 55 0 ° C ) | Steel shell | Total: ¥ 450000 Yuan |

2T One belt two intermediate frequency furnace | GWST -2T / 2400KW | 6* 660 V | 1 8 00KW | 3 2 00v | 580 ±5% kW.h/t ( 1 55 0 ° C ) | Steel shell | Total: ¥ 550000 Yuan |

3T One belt two intermediate frequency furnace | GWST -3T/3000KW | 6* 660 V | 2 500KW | 3 6 00v | 580 ±5% kW.h/t ( 1 55 0 ° C ) | Steel shell | Total: ¥ 750000 Yuan |

5T One belt two intermediate frequency furnace | GWST -3T/4000KW | 6* 660 V | 35 00KW | 3 6 00v | 580 ±5% kW.h/t ( 1 55 0 ° C ) | Steel shell | Total: ¥ 1550000 Yuan |

5. What are the advantages of One belt two intermediate frequency furnace ?

1. The rectifier circuit is always in the all-on state, and the boost power is realized by adjusting the current of the series inverter bridge. Therefore, the entire operation process (including low power, medium power, high power) can ensure that the equipment is always in a high efficiency stage. 20% less than normal equipment

2 , equipment power factor ≥ 9 6 % . The higher harmonics meet the standard without interference to the grid. There is no need for reactive power compensation devices and harmonic elimination devices.

3 , full load starting success rate of 100% . 2 sets of electric furnace while having the ability to mass production.

4 , an intermediate frequency power supply can work with 2 furnaces at the same time, the power can be distributed freely, no need to change the furnace switch equipment. The high utilization of the transformer can save half of the transformer capacity.

5 , constant power output, if the grid voltage rises or decreases, the power output can be kept constant, and the full power output can be ensured.

6. It can be kept warm or heated at an accurate temperature when it needs to be melted without interruption . The two electric furnaces can be cast at the same time, and can also be continuously supplied with molten steel.

Six, One belt two intermediate frequency furnace

One to two secondary frequency furnaces are suitable for casting large-scale workpieces that require two furnaces at the same time. It is suitable for one power supply and two furnaces to work at the same time, one for melting another insulation mode. Applicable to the casting production line requires continuous uninterrupted discharge of molten steel and sand mold manufacturing cycle.

Seven, series One belt two intermediate frequency furnace technical features :

One belt two intermediate frequency furnace adopts " series inverter thyristor intermediate frequency power supply technology " , adopts thyristor full control rectifier electric furnace, but does not need it to regulate voltage, only use it to realize soft start and fault as electronic switch, quickly cut off power supply, normal production When the thyristor is always in a fully conducting state, the grid supply has a high power factor and reduces harmonic interference. The rectification control circuit adopts a digital shifting trigger circuit. The digital shifting trigger circuit has the advantages of good repeatability, good stability, good symmetry, strong anti-interference ability, convenient debugging, etc., and long-distance control can be realized if the digital quantity is given.

Eight, the reason to buy One belt two intermediate frequency furnace

8.1 high efficiency

The series inverter uses a half-bridge circuit, the number of main circuit components is relatively reduced, and has a high power factor, so there is higher power.

Good start-up characteristics, can be started at random under full load and heavy load conditions, and the startup success rate is up to 100% . Improve power factor, to ensure that in any power power factor of 96%.

Constant power output, power output is controlled by constant. During the melting process, when the load and temperature change, the load is always full power output, thus shortening the melting time.

8.2 with perfect protection and health monitoring system

Such as: using the sensor to the incoming current, voltage, circuit current, voltage to take the signal, to the double-closed digital circuit for current limiting, voltage limiting, excessive overvoltage and repeated protection, water temperature and water pressure protection. Both KK thyristors and KP thyristors have self-shutdown time protection.

8.3 complete detection system

For the inverter, the working temperature of the filter capacitor is monitored by the temperature switch table. Once the temperature of the cooling water exceeds the set value or a waterway fault occurs, an alarm is issued and the power is turned off. There is water pressure and electric control for the power supply cooling water input, and the cooling water output has a temperature switch table to monitor the undervoltage. The over temperature will give an alarm and cut off the power.

Nine, the latest One belt two intermediate frequency furnace features introduced by our company

First, the use occasion: suitable for casting large workpieces need to produce two furnace steel at the same time. Applicable to one power supply, two furnaces work at the same time, one smelting another insulation mode. Applicable to the casting production line requires continuous uninterrupted discharge of molten steel and sand mold manufacturing cycle.

Second, compared with the traditional parallel: can work in the detuned state, adjust the output power by frequency modulation. Inverter thyristors are not burned in the event of any failure. Can adapt to the working mode of heavy load start-up operation. The thyristor of the rectifier bridge in the whole process of the equipment operation is always in the fully open state, so the power factor of the whole smelting process reaches 0.96 or more. Improve overall operating efficiency and save operating costs. The resonant tank current is close to the DC current, so the loss on the overall line is small and the overall efficiency is improved. Eliminating the work caused by frequent replacement of water-cooled cables or furnace switches reduces the labor intensity of workers.

Ten, One belt two intermediate frequency furnace schematic

11, One belt two intermediate frequency furnace electrical schematic

PREV:No More Articles.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved