Steel plate quenching and tempering production line

Steel plate quenching and tempering production line drill pipe quenching and tempering line

drill pipe quenching and tempering line Medium frequency quenching and tempering production line

Medium frequency quenching and tempering production line Tubing hardening and tempering line

Tubing hardening and tempering line Petroleum oil drill pipe quenching and tempering line

Petroleum oil drill pipe quenching and tempering line Pipe hardening and tempering

Pipe hardening and tempering Grinding rod quenching and tempering

Grinding rod quenching and tempering Drill pipe quenching and tempering

Drill pipe quenching and tempering Φ219-1067 thick-walled steel pipe medium frequency inductio

Φ219-1067 thick-walled steel pipe medium frequency inductio Φ219-1067 thick wall steel pipe medium frequency induction q

Φ219-1067 thick wall steel pipe medium frequency induction q Steel pipe spray quenching production line

Steel pipe spray quenching production line steel pipe quenching and tempering production line

steel pipe quenching and tempering production line Steel grating induction heating system

Steel grating induction heating system Steel rod quenching and tempering production line

Steel rod quenching and tempering production line Single hydraulic prop quenching tempering

Single hydraulic prop quenching tempering 2700KW large diameter steel tube quenching and tempering prod

2700KW large diameter steel tube quenching and tempering prod Quenching and tempering furnaces

Quenching and tempering furnaces Sucker rod quenching and tempering production line

Sucker rod quenching and tempering production line Rebar quenching and tempering production line

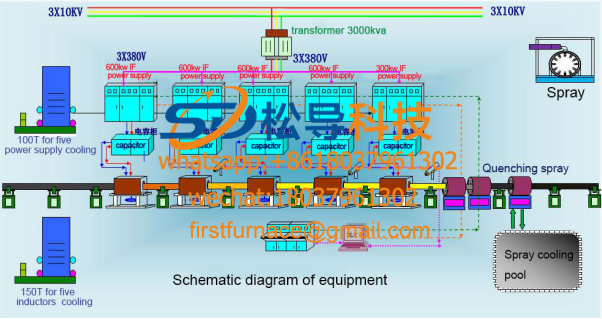

Rebar quenching and tempering production line2700KW large diameter steel tube quenching and tempering production line

The large-diameter steel tube quenching and tempering production line meets the quenching and tempering process of the diameter of φ325~φ1067 steel pipe . The medium frequency induction heating furnace is divided into two areas of heating and equalizing temperature, and the temperature equalizing area can be controlled by independent ring, which can repair the temperature difference of the tube to meet the process requirements. The quenching and tempering of the workpiece are carried out separately in the same production, that is, the quenching process and the tempering process of the large-diameter pipe are respectively completed by the relevant parameters of the preparation .

Tube tempering heating work process: storage, feeding, roller transmission, heating, temperature equalization, discharging, cutting, etc.

Tube quenching heating work process: storage, feeding, roller transmission, heating, temperature equalizing, spraying, cooling, discharging, cutting, etc.

Heating control is divided into automatic control and manual control. The heating temperature is ring control and manual control, and the maximum workpiece exit temperature should meet the specified process requirements of the workpiece.

The medium frequency induction heating furnace and the heat preservation electric furnace are used to realize the heating function required by the following technologies:

(1) Workpiece name: oil casing, high pressure furnace tube, pipe, etc.

(2) (2) Workpiece diameter range: Φ325mm-Φ1067mm

(3) Tube wall thickness: 10mm-30mm.

(4) Length of heatable tube: 6.0m-13m.

(5) Tube heating maximum temperature: 1050 °C.

(6) Maximum temperature difference (circumferential and radial): ±15°

(7) Tube walking speed: 3mm/S-30mm/S;

(8) Tube motion and sensor power control can realize linkage control with PLC and automatic temperature control.

(9) Process requirements: The temperature of the rear tube heated to 1050 ° C.

(10) Production: 5 tons / hour

Process parameters of large diameter steel tube quenching and tempering production line :

Φ325mm-Φ1067mm range. The induction heating temperature is 1050 °C. Production: 18,000 tons / year.

Frequency induction furnace using multiple KGPS frequency power supply and a plurality of sensors into groups. Quenching main heating zone: a power source equipped with a sensor, so that the power supply can control independently an induction may increase the accuracy of heating temperature, heating may be achieved for each matching inductor stepless adjustable power, and can realize closed-loop temperature Control . The heating unit uses four independent heating units, each unit uses a 600KW medium frequency power supply with a 800-1000mm long sensor. The advantages are: single power is small, stability is high, and the independent frequency of each power supply can be increased according to the pipe specification, and the heating efficiency is improved.

Tempering isothermal heating zones: 1 300KW and the power control IF, IF power with separate sensors, temperature sensors have holes, with far-infrared temperature of the tube temperature measurement and control. The sensor length is 800-1000mm .

Large diameter steel tube quenching and tempering production line configuration and price selection

Serial number | content | Quantity | price | Remarks | |

1 | S11-630kvA power transformer | 1 set | 10000 | ||

2 | Thyristor intermediate frequency power supply KGPS- 5 0 0/1 | 1 set | 10000 | ||

3 | Quenching transformer | 1 set | 10000 | ||

3 | Quenching induction heater | 10000 | Includes water cooled rails | ||

3 .1 | GTR 18 | 10000 | |||

3.2 | GTR 25 | 10000 | |||

3.3 | GTR 29 | 10000 | |||

3.4 | GTR 36 | 10000 | |||

4 | Tempering induction heater | 10000 | Includes water cooled rails | ||

4 .1 | GTR 18 | 10000 | |||

4.2 | GTR 25 | 10000 | |||

4.3 | GTR 29 | 10000 | |||

4.4 | GTR 36 | 10000 | |||

5 | Quenching induction heater bed | 1 set | 10000 | ||

6 | Tempering induction heater bed | 1 set | 10000 | ||

14 | Feeding bed | 1 set | 10000 | ||

8 | Cutting end bed | 10000 | |||

9 | Feeding mechanism | 10000 | |||

10 | Cutting mechanism | 10000 | |||

11 | Drive roller mechanism | 10000 | |||

12 | Press roller feeding device | 1 set | 10000 | ||

13 | Quenching water spray device | 10000 | |||

14 | Electrical control core | 1 set | 10000 | ||

14 . 1 | Configuration Software (MCGS system) | 10000 | |||

14 . 2 | Programmable controller (SIEMENS SIMATIC S 14 - 3 00) | 10000 | |||

14 . 3 | LCD screen | 10000 | |||

14 . 4 | Double colorimetric infrared thermometer ( Retro, USA) | 10000 | |||

14 . 5 | Photoelectric switch | 10000 | |||

14 . 6 | Control cabinet (including variable frequency drive equipment) | 10000 | |||

14 . 7 | Console | 10000 | |||

15 | Cooling water system ( ZXZ - 60T ) section | 1 set | 10000 | ||

10000 | |||||

Water pipe ppr | 10000 | Water cooling tower within 10 meters from the power cabinet | |||

16 | IF power incoming copper busbar | 1 set | 10000 | ||

17 | Installation and commissioning of electrical and waterways | 1 set | 10000 | ||

18 | Freight | 1 set | 10000 | ||

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved