Steel plate quenching and tempering production line

Steel plate quenching and tempering production line drill pipe quenching and tempering line

drill pipe quenching and tempering line Medium frequency quenching and tempering production line

Medium frequency quenching and tempering production line Tubing hardening and tempering line

Tubing hardening and tempering line Petroleum oil drill pipe quenching and tempering line

Petroleum oil drill pipe quenching and tempering line Pipe hardening and tempering

Pipe hardening and tempering Grinding rod quenching and tempering

Grinding rod quenching and tempering Drill pipe quenching and tempering

Drill pipe quenching and tempering Φ219-1067 thick-walled steel pipe medium frequency inductio

Φ219-1067 thick-walled steel pipe medium frequency inductio Φ219-1067 thick wall steel pipe medium frequency induction q

Φ219-1067 thick wall steel pipe medium frequency induction q Steel pipe spray quenching production line

Steel pipe spray quenching production line steel pipe quenching and tempering production line

steel pipe quenching and tempering production line Steel grating induction heating system

Steel grating induction heating system Steel rod quenching and tempering production line

Steel rod quenching and tempering production line Single hydraulic prop quenching tempering

Single hydraulic prop quenching tempering 2700KW large diameter steel tube quenching and tempering prod

2700KW large diameter steel tube quenching and tempering prod Quenching and tempering furnaces

Quenching and tempering furnaces Sucker rod quenching and tempering production line

Sucker rod quenching and tempering production line Rebar quenching and tempering production line

Rebar quenching and tempering production lineWith an annual output of 20,000 tons, (ф7.1mm, ф9.0mm, ф10.6mm each one third). Among them: ф7.1mm line speed is 105 m / min, ф 9.0 mm line speed is 90 m / min, ф10.6 mm line speed is 65 m / min.

First, the steel bar quenching and tempering production line process

Raw material wire rod - mechanical rust removal - straightening - drawing diameter reduction - nicking - induction heating quenching - induction heating tempering - inspection - crimping finished product - packaging

Second, the steel bar quenching and tempering production line process plan

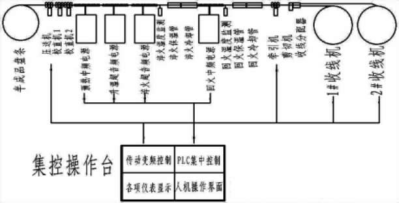

The heat treatment production line is a pipeline type system. The system block diagram is shown in Figure (1). The system can be divided into four parts: electric drive, induction heating, console, data acquisition and other ancillary equipment. The electric drive part consists of 4 motors (1 press machine, 1 tractor, 2 wire take-up machines) and steel bar straightening rollers. Each motor is driven by ABB's inverter; The heating part consists of 4 induction heating machines (2 sets of intermediate frequency power supply, wherein the power of 1# intermediate frequency power supply is P1=500KW, the power of 4# intermediate frequency power supply is P4=250KW. 2#, 3# power supply super audio power supply, power is respectively Composition of P2=320KW and P3=250KW). The 1# thermometer is used to measure the quenching temperature, the 2# thermometer is used to measure the tempering temperature, and finally the shear and line of the PC steel bar. The console is the main control station of the entire production line. The Simens series PLC and touch screen (TP270) jointly monitor the production line.

Third, steel quenching and tempering production line equipment selection

1 , mechanical equipment

A, line planes 2

B , press machine, straightening machine, tractor

C , insulation pipe (length 3 meters) 2 pieces

D , cooling sink (length 4 meters) 2 pieces

E , gear shear (including dispensing device) 1 piece

F , finished product receiving machine 2 pieces

Fourth , steel quenching and tempering production line heating power equipment (including sensors)

A , preheating thyristor intermediate frequency power supply ( 500KW/4KHZ ) 1 set

B , heating IGBT super audio power supply 320KW/30KHZ ) 1 set

C , quenching IGBT super audio power supply 250KW/50KHZ ) 1 set

D , tempered thyristor intermediate frequency power supply ( 250KW/4KHZ ) 1 set

5. Supporting equipment for steel quenching and tempering production line

A , thermometer (domestic, import alternative) one each for high and low temperature

B , centralized console (including 4 inverters , one set of PLC control system)

C , the connection between the control parts of the device

PREV:No More Articles.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved