Round bar heating furnace

Round bar heating furnace 500kg atomized powder special melting furnace

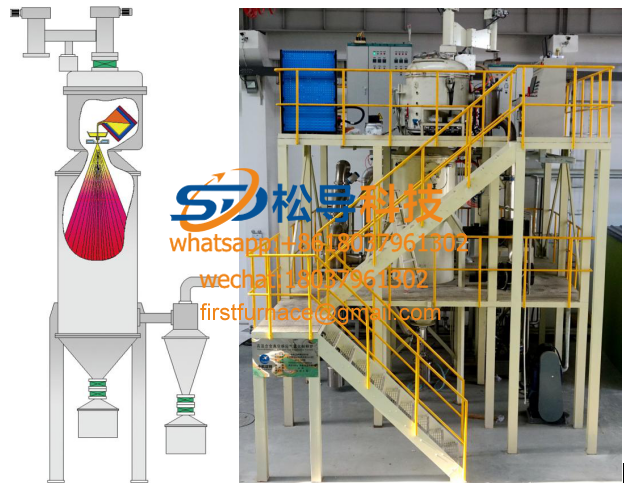

500kg atomized powder special melting furnace Metal powder atomizing equipment

Metal powder atomizing equipment 500kg metal powder atomization melting furnace

500kg metal powder atomization melting furnace 200kg metal powder atomization melting furnace

200kg metal powder atomization melting furnace 100kg atomizing powder special melting furnace

100kg atomizing powder special melting furnace 100kg air atomization milling equipment

100kg air atomization milling equipment  100kg metal powder atomization melting furnace

100kg metal powder atomization melting furnace Metal powder atomization melting furnace

Metal powder atomization melting furnace 50kg metal powder atomization melting furnace

50kg metal powder atomization melting furnace Induction furnace for metal powder manufacturing

Induction furnace for metal powder manufacturing Medium frequency furnace for atomization and milling

Medium frequency furnace for atomization and milling1, the metal powder produced by an induction furnace profile:

This product uses energy-saving medium frequency power supply for induction heating, power 30KW -2500KW , mainly used for remelting and alloying of iron-based alloys, and also for smelting, heating, quenching and atomizing and milling of nickel-based, copper-based raw materials and non-ferrous metals such as aluminum, gold and silver. The capacity of this series of products is small, generally 30Kg - 1000 Kg . In the process of pouring, the molten metal is always poured into the gate through the spout, the spout has no back and forth movement, and the precision of the fixed point casting is high. Pouring does not require tundish, the nozzle is very short, and the medium temperature is lowered during the casting process, so it is widely used in places where the fixed point pouring operation is required, such as powder metallurgy water (gas) atomization copper powder, iron powder, stainless steel. Powder and so on.

Second, induction furnace for metal powder manufacturing

Features:

( 1) devices of high quality steel, high strength, long life

( 2 ) The spout has no back and forth motion, and the precision of the fixed point casting is high.

( 3 ) Simple operation process, less burning loss and reliable operation

( 4 ) The metal liquid is stirred by electromagnetic force, and the temperature and composition are uniform.

( 5 ) Fast melting and high production efficiency

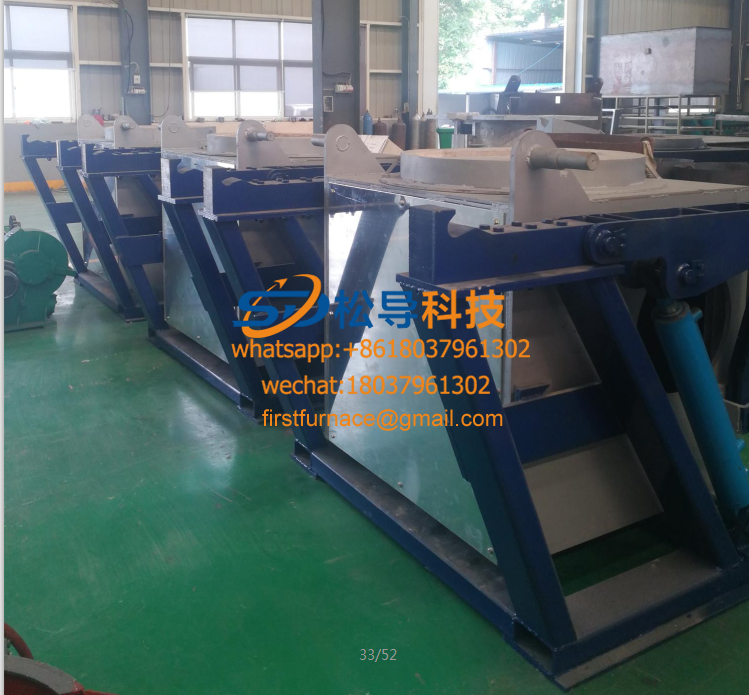

( 6 ) Hydraulic tilting furnace, stepless speed regulation, smooth and safe

( 7 ) Easy to start and stop, easy to control furnace temperature

( 8 ) yoke shield leakage flux reduces external reluctance

Summary of technical parameters of induction furnace for metal powder manufacturing

model | Rated Capacity | rated power | frequency | Line voltage | IF output voltage | Melting time | power consumption | transformer |

T | KW | KHZ | V | V | Minutes/T | KWH/T | KVA | |

KGPS- 15 | 0.015 | 50 | 2.5 | 380 | 750 | 40 | 680 | 30 |

KGPS- 50 | 0.05 | 1 00 | 2.5 | 380 | 750 | 40 | 680 | 100 |

KGPS- 100 | 0. 1 | 160 | 2.5 | 380 | 750 | 50 | 650 | 160 |

KGPS- 200 | 0.2 | 250 | 2.5 | 380 | 750 | 60 | 640 | 250 |

KGPS- 300 | 0.3 | 300 | 2.5 | 380 | 750 | 60 | 640 | 315 |

KGPS-500 | 0.5 | 400 | 2 | 380 | 750 | 40 | 640 | 430 |

KGPS- 1 000 | 1 | 800 | 1 | 380 | 750 | 60 | 640 | 1000 |

What are the main production costs of atomized metal powder?

The main cost is electricity, followed by gas (if it is aerosolization), water (if it is water atomization)

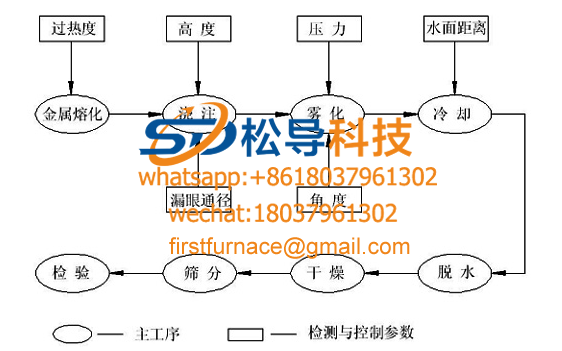

Water atomizing method milling process for preparation of metal powder:

First, the metal or alloy is melted and refined in the induction furnace, and the molten metal liquid is poured into the heat preservation crucible. During the flow of the metal liquid along the guide tube, the ultra-high pressure water flows through the nozzle to break the metal liquid into a large number of fine metal droplets, and is small. The droplets form sub-spherical or irregular shaped particles under the action of surface tension and rapid cooling of water during flight. The atomized metal particles are solidified, settled in the atomization tower, and finally fall into the powder collecting tank. Collect and separate. Moreover, by adjusting different parameters in the milling process, metal powders of various particle size distributions and morphologies can be obtained, thereby better satisfying mechanical manufacturing, automobile industry, aerospace and metal injection molding, friction materials, oil-impregnated bearings, A wide range of requirements in the field of powder metallurgy, such as structural parts and diamond tools.

High pressure water atomization milling process roadmap

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved