Round bar heating furnace

Round bar heating furnace 500kg atomized powder special melting furnace

500kg atomized powder special melting furnace Metal powder atomizing equipment

Metal powder atomizing equipment 500kg metal powder atomization melting furnace

500kg metal powder atomization melting furnace 200kg metal powder atomization melting furnace

200kg metal powder atomization melting furnace 100kg atomizing powder special melting furnace

100kg atomizing powder special melting furnace 100kg air atomization milling equipment

100kg air atomization milling equipment  100kg metal powder atomization melting furnace

100kg metal powder atomization melting furnace Metal powder atomization melting furnace

Metal powder atomization melting furnace 50kg metal powder atomization melting furnace

50kg metal powder atomization melting furnace Induction furnace for metal powder manufacturing

Induction furnace for metal powder manufacturing Medium frequency furnace for atomization and milling

Medium frequency furnace for atomization and millingFirst, the equipment description

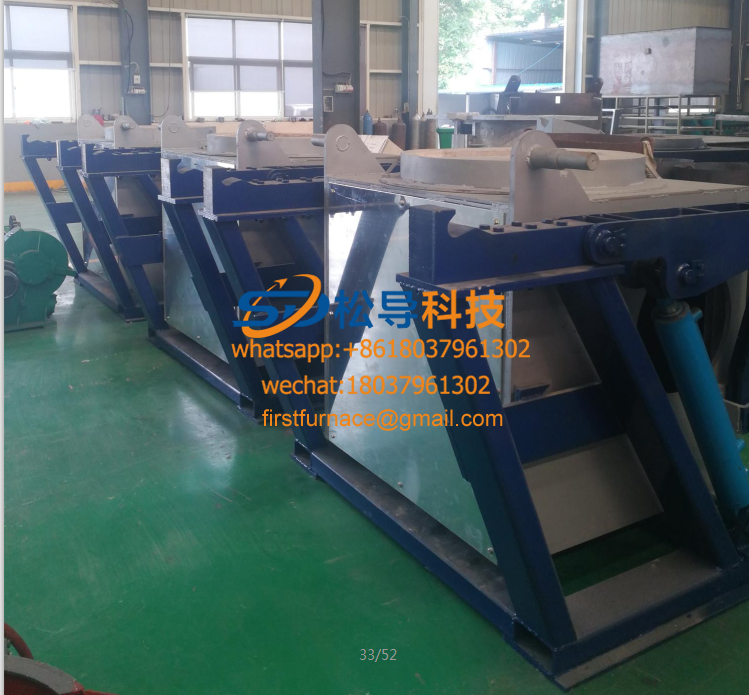

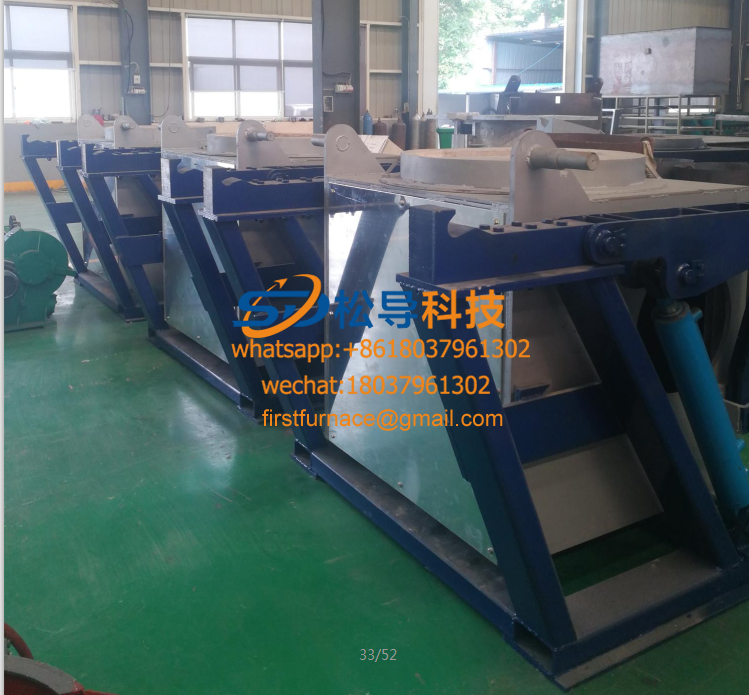

500kg metal powder atomization melting furnace overview: This product belongs to the new atomization milling equipment, 500kg metal powder atomization melting furnace , unique hydraulic tilting rod linkage mechanism, which can always make the whole process of melting and pouring out the melt. The metal solution is poured into a small diameter receiving port, which is a device for producing metal powder and the like by a water ( gas ) atomization process.

500kg metal powder atomization melting furnace body and hydraulic tilting furnace mechanism. The furnace body runs at a uniform speed, the height difference of the nozzle is small, and the liquid discharge is continuously stable. The running curve of the nozzle is fixed by the trajectory and optimized by the computer. The special curved template is used to guide the locking, so that the furnace body is uniformly and orderly discharged from the continuous liquid discharge to the fixed point. The tilting angle of the furnace body: 0 ~ 95° ( 0° refers to the horizontal position of the furnace mouth); the furnace has high stability of turning, and the positioning accuracy of the discharge port is high (the distance between the outlet and the leakage of the melting furnace is less than 50mm ), and the pouring center changes. The error is small, the nozzle does not move back and forth when atomizing the steel, and the precision of the fixed point casting is high, and the front and back error does not exceed 30 mm , and the stability of the metal liquid flow is ensured. The maintenance and replacement of complete sets of equipment adopts modular design, easy maintenance and easy maintenance, which greatly improves production efficiency.

500kg metal powder atomization melting furnace technical parameters

model | Rated Capacity | rated power | frequency | Line voltage | IF output voltage | Melting time | power consumption | transformer |

T | KW | KHZ | V | V | Minutes/T | KWH/T | KVA | |

KGPS- 15 | 0.015 | 50 | 2.5 | 380 | 750 | 40 | 680 | 30 |

KGPS- 50 | 0.05 | 1 00 | 2.5 | 380 | 750 | 40 | 680 | 100 |

KGPS- 100 | 0. 1 | 160 | 2.5 | 380 | 750 | 50 | 650 | 160 |

KGPS- 200 | 0.2 | 250 | 2.5 | 380 | 750 | 60 | 640 | 250 |

KGPS- 300 | 0.3 | 300 | 2.5 | 380 | 750 | 60 | 640 | 315 |

KGPS-500 | 0.5 | 400 | 2 | 380 | 750 | 40 | 640 | 430 |

KGPS- 1000 | 1 | 800 | 1 | 380 | 750 | 60 | 640 | 1000 |

What are the main production costs of atomized metal powder?

The main cost is electricity, followed by gas (if it is aerosolization), water (if it is water atomization)

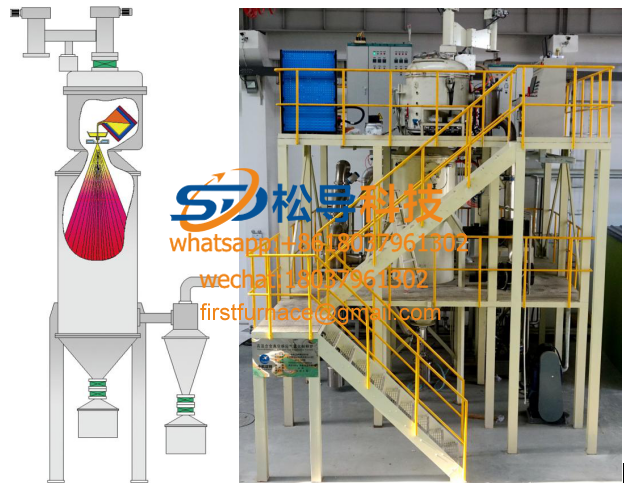

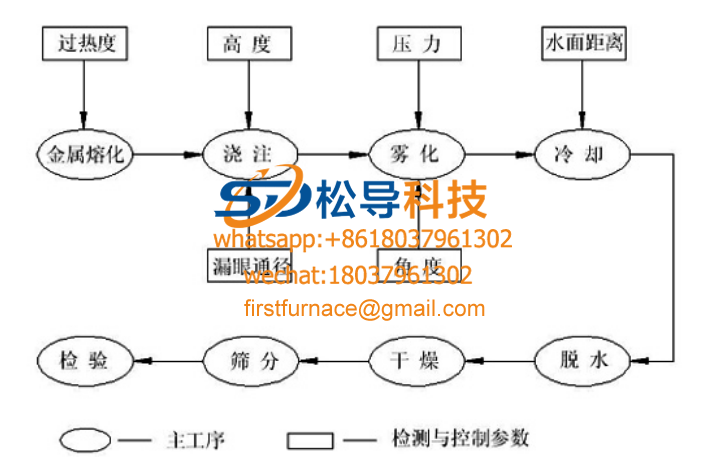

Water atomizing method milling process for preparation of metal powder:

First, the metal or alloy is melted and refined in the induction furnace, and the molten metal liquid is poured into the heat preservation crucible. During the flow of the metal liquid along the guide tube, the ultra-high pressure water flows through the nozzle to break the metal liquid into a large number of fine metal droplets, and is small. The droplets form sub-spherical or irregular shaped particles under the action of surface tension and rapid cooling of water during flight. The atomized metal particles are solidified, settled in the atomization tower, and finally fall into the powder collecting tank. Collect and separate. Moreover, by adjusting different parameters in the milling process, metal powders of various particle size distributions and morphologies can be obtained, thereby better satisfying mechanical manufacturing, automobile industry, aerospace and metal injection molding, friction materials, oil-impregnated bearings, A wide range of requirements in the field of powder metallurgy, such as structural parts and diamond tools.

High pressure water atomization milling process roadmap

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved