square steel medium frequency induction heating equipment

square steel medium frequency induction heating equipment square steel medium frequency induction heating furnace

square steel medium frequency induction heating furnace square steel medium frequency forging furnace

square steel medium frequency forging furnace Square steel heating furnace

Square steel heating furnace Square steel heating electric furnace

Square steel heating electric furnace Square steel induction heating furnace

Square steel induction heating furnace square steel forged medium frequency heating furnace

square steel forged medium frequency heating furnace Square steel forging heating equipment

Square steel forging heating equipment Billet electric heating furnace

Billet electric heating furnace Square billet electric induction heating furnace

Square billet electric induction heating furnace Square steel forged heating electric furnace

Square steel forged heating electric furnaceFirst, use: Fanggang heating furnace is used for square steel, square billet and steel billet before heating.

Second, the square steel heating furnace heating square steel parameters are as follows

Square steel size (mm) | Power kw | Heating temperature |

6 × 6 | 10 | 1100 °C |

10x10 | 30 | 1100 °C |

40x40 | 60 | 1100 °C |

60x60 | 120 | 1100 °C |

100x100 | 200 | 1100 °C |

150x150 | 300 | 1100 °C |

200x200 | 500 | 1100 °C |

300x300 | 600 | 1100 °C |

500x500 | 1000 | 1100 °C |

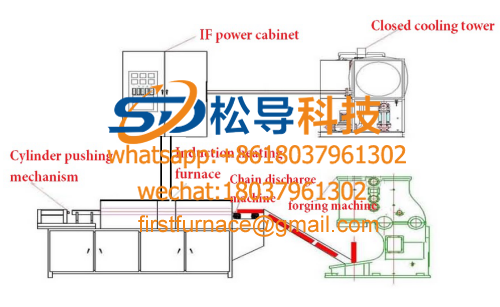

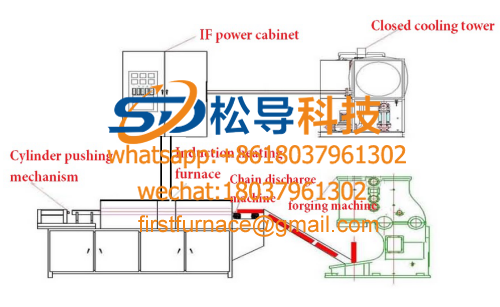

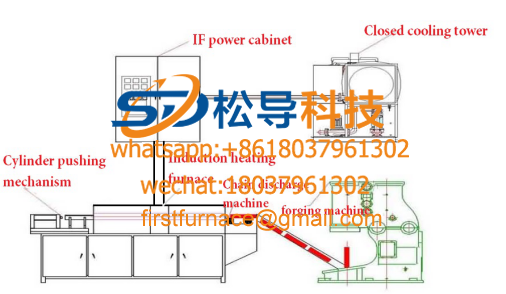

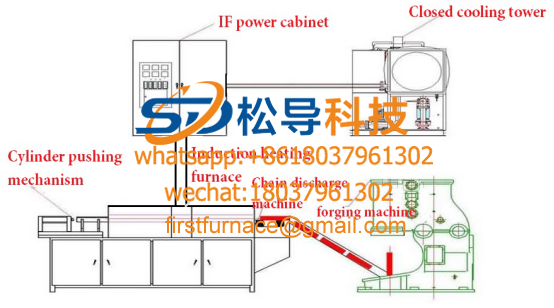

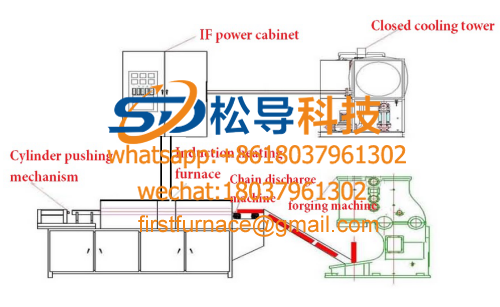

Third, the schematic diagram of the square steel heating furnace:

Fourth, the method of selecting the structure of the square steel heating furnace

The main components of the square steel heating furnace are sensors, furnace bodies, power supplies, capacitors and control systems. Under the action of the alternating electromagnetic field in the induction heating furnace, eddy current is generated inside the workpiece to achieve the heating effect. BecauseFanggang heating furnace is a non-standard customized product, it can customize the production of square steel heating furnace according to the individual requirements of users , and can choose the configuration scheme with high degree of automation: automatic feeding machine, discharging machine, discharging sorter , closed cooling water circulation system, etc.

The main components of the square steel heating furnace are sensors, furnace bodies, power supplies, capacitors and control systems. Under the action of the alternating electromagnetic field in the induction heating furnace, eddy current is generated inside the workpiece to achieve the heating effect. Because Yuantuo electromechanical steel forging heating equipment belongs to non-standard customized products, Yuantuo Electromechanical can customize the production of square steel heating furnace according to the individual requirements of users , and can choose the configuration scheme with high degree of automation: automatic feeding machine, discharging machine , discharge sorter, closed cooling water circulation system, etc.

Five, Fanggang heating furnace PLC intelligent control system :

Provide touch screen or remote console control according to user needs

Man-machine interface, easy to operate

Real-time adjustment of operating parameters of the device

Real-time control of the heating process with recording function

Different international language switching

Six, the advantages of square steel heating furnace

1. The whole machine has high efficiency , the whole machine efficiency can reach more than 85% , the working frequency is high , and the current high is up to 1000 kHz , which realizes long-term continuous production and provides user production efficiency;

2 , high reliability , unique circuit design , the power module unit used to form the system , the damage of individual power modules can not affect the work of the square steel heating furnace , so that the reliable operation of the equipment has been substantially improved;

3 , energy saving : Compared with the high-frequency induction heating equipment of the same power level , the power saving is more than 50% , and the water saving is more than 70% . The output power is convenient to adjust , the reaction speed is fast , the control is accurate , and the heating condition can be arbitrarily selected;

4 , due to the full use of semiconductor devices , heating forging equipment has a long life;

5, low failure rate, low operating voltage (380V), high safety, ease of use, inspection and maintenance. Simple structure, spare simple, small size, light weight.

Seven, the advantages of square steel heating furnace :

1. The square steel heating furnace body adopts double insulation treatment, the service life and reliability are improved, the thin furnace lining design, the electric energy conversion efficiency is extremely high, and the purpose of energy saving and consumption reduction is achieved;

2. IF voltage double voltage output, output slot width copper bus small gap design, reduce line power loss, power saving up to 10% - 15% ;

3. Using high-quality materials and computer design to achieve high-performance work with high matching, power saving, saving money for the enterprise;

4. The core of the intermediate frequency power supply control is computer controlled. The blank is monitored in the induction heating furnace. The valuable information, including the optimized setting parameters, are stored for recall.

Eight, square steel electric heating forging furnace working principle:

The square steel heating furnace is automatically operated, has a temperature measuring device, measures the temperature of the square steel during the heating process, and controls the production tempo with a time relay. When starting to feed, firstly, the temperature measuring head rotates by an angle, and the feeding pusher moves to push a square steel into the inductor. The heated square steel is pushed out of the inductor and falls onto the roller table. Transfer to the end of the roller table, the top material mechanism is raised to turn the square steel onto the discharge chute, and the square steel is rolled onto the extruder for extrusion. At the same time of conveying, the feeder of the feed is returned, and a square steel is rolled in the feed chute for the next feeding.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved