Bearing sleeve heater

Bearing sleeve heater Gear heating automatic equipment

Gear heating automatic equipment Rolling mill bearing heater

Rolling mill bearing heater DM-1000steam turbine guardring induction heater

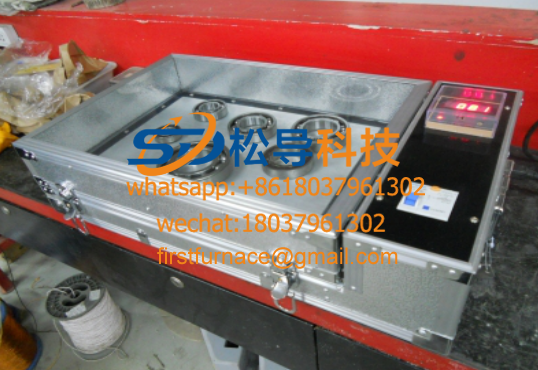

DM-1000steam turbine guardring induction heater Flat bearing heater

Flat bearing heater Pulley heater

Pulley heater Inner bore bearing heater

Inner bore bearing heater Ds-2000 Induction Heater-Hub Heater

Ds-2000 Induction Heater-Hub Heater Combined bearing heater

Combined bearing heater Multi-station drum induction heater

Multi-station drum induction heater Multi-station gear heater

Multi-station gear heater Gear heater

Gear heater Gear heating with automatic equipment

Gear heating with automatic equipment Gearbox housing heater details

Gearbox housing heater details Ds-1000bearing induction heater

Ds-1000bearing induction heater Ds-800 steam turbine guard ring induction heater

Ds-800 steam turbine guard ring induction heater Ds-600 bearing induction heater-bearing induction heater

Ds-600 bearing induction heater-bearing induction heaterGHJ-H Set of heater selection parameters

Work rate | 0.5-50 (KW) | temperature control | 0-180°C |

Electricity source Electricity Pressure | 220V / 380V | time control | 0-99'59'' |

work Make Electricity flow | 2.0-75 (A) | Continuous installation | Have |

Adapt to bearing outer diameter | 10mm-1000mm | Temperature retention | Have |

suitable should Bearing width degree | 5-300mm | Automatic demagnetization | Have |

maximum axis Undertake weight the amount | 1000Kg | Power self-adjustment | Have |

Number of assembled bearings at one time | Optional | Control panel (display) | Digital display |

Manual / Auto | Optional | Forced air cooling | Have |

the Lord machine weight the amount | Determined by selected power | Overheating protection | Have |

Detailed introduction

This heating device is specially designed for the production of "angular contact bearings". The induction heating device can quickly heat the outer ring of the bearing to expand and easily complete the bearing assembly. In order to adapt to the assembly requirements of different bearing models, a host with a number of sensors is used to expand the assembly range and save money. The use of bearings and sleeve heaters can increase production efficiency and prevent contamination of the outer ring of the bearing due to oil bath heating. Compared with the existing "flat heating" and "oil bath heating" efficiency is more than 5 times, energy saving is more than 80%, convenient and fast, no pollution, and the product quality has been greatly improved. Using induction heating, can easily achieve automatic assembly of the bearing, reducing the bearing human intervention during assembly, the assembling accuracy is improved, the quality of the bearing will increase.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved