Rolling mill detailed introduction

Rolling mill detailed introduction Steel production line detailed introduction

Steel production line detailed introduction Universal mill detailed introduction

Universal mill detailed introduction Pusher detailing

Pusher detailing Four-roll mill detailed introduction

Four-roll mill detailed introduction Three-roll mill detailed introduction

Three-roll mill detailed introduction Hot rolling mill detailed introduction

Hot rolling mill detailed introduction Aluminum casting mill details

Aluminum casting mill details Aluminum magnesium silicon alloy rod continuous casting and r

Aluminum magnesium silicon alloy rod continuous casting and r Six-roll cold rolling mill

Six-roll cold rolling mill Continuous rolling mill

Continuous rolling mill Cold rolled rebar equipment details

Cold rolled rebar equipment details Detailed introduction of cold rolling steel

Detailed introduction of cold rolling steel Straightening machine details

Straightening machine details Roller table, lifting table details

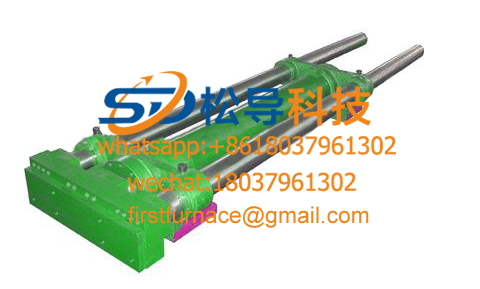

Roller table, lifting table details Billet fixture

Billet fixture Two-roll cold rolling mill

Two-roll cold rolling mill Short stress rolling mill detailed introduction

Short stress rolling mill detailed introduction Fixed-length cutting machine detailed introduction

Fixed-length cutting machine detailed introduction strip production line

strip production lineIt mainly produces rolling mills, cold rolling mills, hot rolling mills, aluminum foil rolling mills, four-roll mills, rolling mill parts and ball mills. We provide free installation, commissioning and training of technicians and other related services. Users are welcome to come to consult and negotiate.

The 650 rolling mill is generally used in the rolling mill production line by a blanking machine. It is used to roll the slab from the furnace into the desired shape, size, texture and properties for the lower mill to bite. Because the temperature of the rolled piece just coming out of the heating furnace is high, the plasticity of the steel is good, the deformation resistance is low, and the pressing amount of the blanking machine is also large, generally reaching about 50%, because the pressing amount is large, so the blanking machine The roll is also large, and the rolled product has good performance and no residual stress. The structure inside the rolled piece is dense, the crystal grain is small, and there is no bubble.

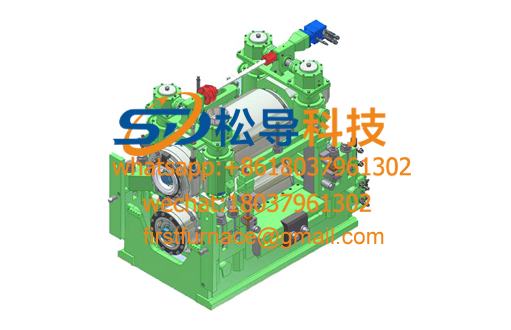

The 200-350 rolling mill is a device for realizing the metal rolling process. It refers to the equipment that completes the whole process of rolling material production, including main equipment, auxiliary equipment, lifting transportation equipment and auxiliary equipment. However, the so-called rolling mills are often referred to only as the main equipment. The working frame is composed of a roll, a roll bearing, a rolling mill guide, a frame, a rail seat, a roll adjusting device, an upper roll balancing device and a roll changing device.

Type 250 rolling mill, the diameter of the rolls is 235-275 mm. The roll head has a diameter of 150 mm and the roll face length is 500-700 mm. The large feed is 60X60. The rolling mill is mainly used for rolling small bars and adopts a three-roll working machine base. The main row of the rolling mill consists of three basic parts: the motor, the transmission and the actuator. The configuration adopted is electric motor - reducer - gear base - rolling mill. The rolling mill reducer adopts ZD60-ZD70 type with a center distance of 600-700mm. Since the steering and rotational speed of the rolls are irreversible, the prime mover uses a high-speed AC main motor with a lower cost. Considering that the rolling load is very uneven, in order to balance the motor load and reduce the capacity of the motor, a flywheel is added between the speed reducer and the motor. Gear base: Its purpose is to transmit torque to the work roll. The design uses three cylindrical herringbone gears of equal diameter to be arranged in a row in the vertical plane and enclosed in a closed box. Coupling: A safety coupling is used between the gear unit and the gear housing. The plum coupling shaft coupling used in the main coupling.

Contact us will have a very low price, please consult the specific price. Firstfurnace@gmail.com

PREV:No More Articles.

NEXT:250 rolling mill

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved