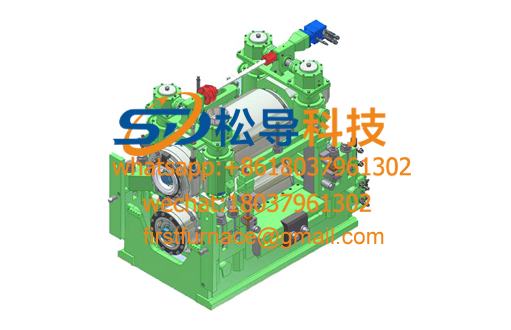

Rolling mill detailed introduction

Rolling mill detailed introduction Steel production line detailed introduction

Steel production line detailed introduction Universal mill detailed introduction

Universal mill detailed introduction Pusher detailing

Pusher detailing Four-roll mill detailed introduction

Four-roll mill detailed introduction Three-roll mill detailed introduction

Three-roll mill detailed introduction Hot rolling mill detailed introduction

Hot rolling mill detailed introduction Aluminum casting mill details

Aluminum casting mill details Aluminum magnesium silicon alloy rod continuous casting and r

Aluminum magnesium silicon alloy rod continuous casting and r Six-roll cold rolling mill

Six-roll cold rolling mill Continuous rolling mill

Continuous rolling mill Cold rolled rebar equipment details

Cold rolled rebar equipment details Detailed introduction of cold rolling steel

Detailed introduction of cold rolling steel Straightening machine details

Straightening machine details Roller table, lifting table details

Roller table, lifting table details Billet fixture

Billet fixture Two-roll cold rolling mill

Two-roll cold rolling mill Short stress rolling mill detailed introduction

Short stress rolling mill detailed introduction Fixed-length cutting machine detailed introduction

Fixed-length cutting machine detailed introduction strip production line

strip production line1. Overview of straightening machine

The straightening machine is a device for straightening metal profiles, bars, pipes, wires, and the like. The straightening machine presses the bar or the like by a straightening roller to change the straightness. There are generally two rows of straightening rolls, varying in number. There are also two-roll straighteners that rely on angular changes in two rolls (intermediate concave, hyperbolic rolls) to straighten materials of different diameters. The main types are pressure straightening machine, balance roller straightening machine, shoe rolling straightening machine, rotary turning straightening machine and so on.

Contact us will have a very low price, please consult the specific price. firstfurnace@gmail.com

2 , straightening process of straightening machine

The position of the roller is at an angle to the direction of movement of the straightened product. Two or three large are active pressure rollers, which are rotated in the same direction by the motor belt, and several small rollers on the other side are driven pressure rollers. It is rotated by the rotating round bar or the friction of the pipe. In order to achieve the required compression of the rolls to the article, the small rolls can be adjusted at the same time or separately forward or backward. Generally, the greater the number of rolls, the higher the accuracy of the finished product after straightening.After the product is bitten by the roller, it continuously moves in a straight line or a rotation, thereby subjecting the product to various deformation, bending, crushing and the like, and then achieving the purpose of straightening.

2 , straightening machine selection method

model | Roll distance Mm | Number of rollers One | Adjustment vertical Mm | distance Level Mm | Large plastic distance Bending force KN.M | Straightenable steel large size or specification | Large straightening speed m/s | Transmission power KW | Axial adjustment | |||||

Round steel | Square steel | Rail | Angle steel | Channel steel | I-beam | |||||||||

Mm | Mm | Kg | # | # | # | |||||||||

YJ-250 | 250 | 13+1 | 45 | 15 | 2.86 | 35 | 30 | 5 | 6.3 | 6.5 | -- | 2.6 | 30 | Manual |

YJ-350 | 350 | 9+1 | 80 | 20 | 8.35 | 50 | 45 | 8 | 8 | 10 | 10 | 2 | 45 | Manual |

YJ-450 | 450 | 9+1 | 100 | 20 | 15.5 | 60 | 55 | 12 | 12 | 14 | 14 | 2 | 75 | Manual |

YJ-550 | 550 | 9+1 | 120 | 25 | 33.5 | 85 | 80 | 18 | 14 | 20 | 20 | 2 | 75 | Manual |

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved