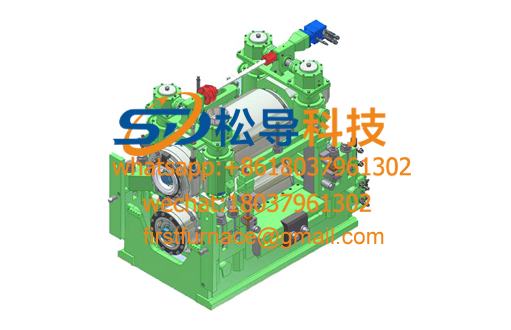

Rolling mill detailed introduction

Rolling mill detailed introduction Steel production line detailed introduction

Steel production line detailed introduction Universal mill detailed introduction

Universal mill detailed introduction Pusher detailing

Pusher detailing Four-roll mill detailed introduction

Four-roll mill detailed introduction Three-roll mill detailed introduction

Three-roll mill detailed introduction Hot rolling mill detailed introduction

Hot rolling mill detailed introduction Aluminum casting mill details

Aluminum casting mill details Aluminum magnesium silicon alloy rod continuous casting and r

Aluminum magnesium silicon alloy rod continuous casting and r Six-roll cold rolling mill

Six-roll cold rolling mill Continuous rolling mill

Continuous rolling mill Cold rolled rebar equipment details

Cold rolled rebar equipment details Detailed introduction of cold rolling steel

Detailed introduction of cold rolling steel Straightening machine details

Straightening machine details Roller table, lifting table details

Roller table, lifting table details Billet fixture

Billet fixture Two-roll cold rolling mill

Two-roll cold rolling mill Short stress rolling mill detailed introduction

Short stress rolling mill detailed introduction Fixed-length cutting machine detailed introduction

Fixed-length cutting machine detailed introduction strip production line

strip production line1 , push steel selection method

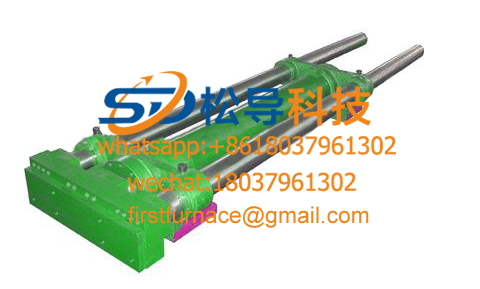

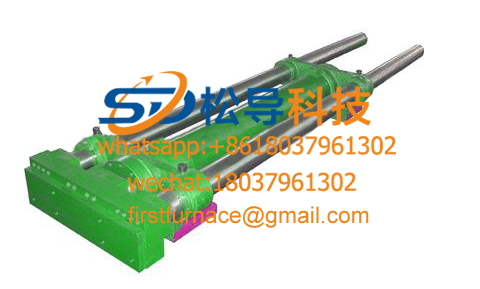

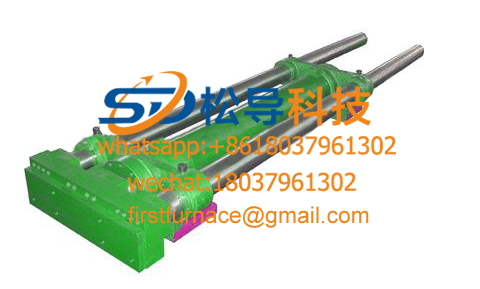

Pusher billet rolling line is dedicated to promote heating furnace equipment, the old production line often by mechanical pushers, a large volume high prices failure rate. Complicated maintenance. With the development of rolling steel production, the new hydraulic pusher gradually replaced the old mechanical pusher, making full use of the advantages of large thrust, small volume and convenient operation of the hydraulic cylinder and hydraulic system, which greatly simplified the pushing process and equipment cost. Greatly reduced, very popular with users. The main models of hydraulic pusher are 300 tons, 240 tons, 220 tons, 180tons, 160 tons, 120 tons, 80 tons, 60 tons, 30 tons, 20 tons, 15 tons, which are used in different pusher occasions. , playing an increasingly important role in rolling steel production.

The hydraulic pusher is a special equipment for heating the billet into the heating furnace in the rolling steel production line. It fully utilizes the advantages of large output of the hydraulic cylinder and hydraulic system, and small volume and convenient operation. The reduction of the pushing process is also reduced, and the equipment cost is also reduced. Compared with the old mechanical pusher, the floor space is reduced to 1/2 - 1/3 , the equipment investment is saved by half, and the spare parts cost is mechanical push steel. 1/6 — 1/10 of the machine . The hydraulic pusher is easy to operate and has long-term stability.

The TG series new hydraulic pusher produced by the company solves the problem of sealing and wear of the working cylinder under high temperature and high dust, and fundamentally solves the problem of difficult maintenance and short service life of the hydraulic system. Companies can be designed 200KN to 6000KNhydraulic pushers, the user may need to use, simple Pusher structure, convenient operation, good rigidity, high efficiency, long-term performance stability, can be used alone, also duplex and dried, multi-machine and with, It is an ideal equipment for new steel companies to solve small footprints and low investment by manufacturers.

2 , TG series pusher equipment structure, process, layout method.

The TG series of new hydraulic pusher consists of the fuselage, front and rear beams, double guide bars, pushers and main hydraulic cylinders, and hydraulic pumping stations.

3 , TG series pusher selection method

Product number | Thrust(KN) | Working stroke(mm) | Propulsion speed m/s | Return speed m/s | Motor power (kW) |

TG-20 | 200 | 2000 | 4-5m/min | 7-8m/min | 5.5 |

TG-30 | 300 | 2000 | 4-5m/min | 7-8m/min | 5.5 |

TG-60 | 600 | 1600 | 4-5m/min | 7-8m/min | 7.5 |

TG-80 | 800 | 1600 | 4-5m/min | 7-8m/min | 7.5 |

TG-120 | 1200 | 1600 | 4-5m/min | 7-8m/min | 11 |

TG-160 | 1600 | 1600 | 4-5m/min | 7-8m/min | 13 |

TG-220 | 2200 | 1600 | 3-4m/min | 6-7m/min | 18 |

TG-300 | 3000 | 1800 | 3-4m/min | 6-7m/min | twenty two |

Can be designed according to the special needs, other parameters for producing a screw, hydraulic Pusher.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved