Rolling mill detailed introduction

Rolling mill detailed introduction Steel production line detailed introduction

Steel production line detailed introduction Universal mill detailed introduction

Universal mill detailed introduction Pusher detailing

Pusher detailing Four-roll mill detailed introduction

Four-roll mill detailed introduction Three-roll mill detailed introduction

Three-roll mill detailed introduction Hot rolling mill detailed introduction

Hot rolling mill detailed introduction Aluminum casting mill details

Aluminum casting mill details Aluminum magnesium silicon alloy rod continuous casting and r

Aluminum magnesium silicon alloy rod continuous casting and r Six-roll cold rolling mill

Six-roll cold rolling mill Continuous rolling mill

Continuous rolling mill Cold rolled rebar equipment details

Cold rolled rebar equipment details Detailed introduction of cold rolling steel

Detailed introduction of cold rolling steel Straightening machine details

Straightening machine details Roller table, lifting table details

Roller table, lifting table details Billet fixture

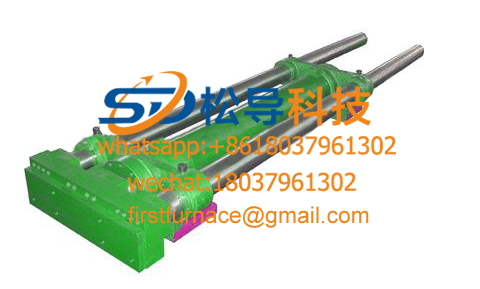

Billet fixture Two-roll cold rolling mill

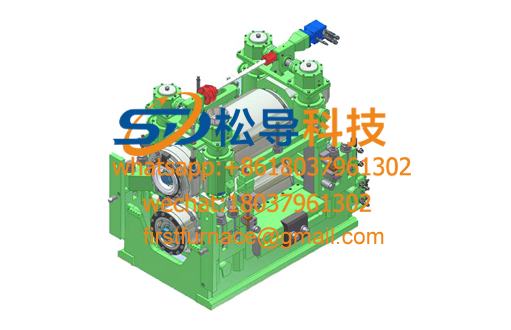

Two-roll cold rolling mill Short stress rolling mill detailed introduction

Short stress rolling mill detailed introduction Fixed-length cutting machine detailed introduction

Fixed-length cutting machine detailed introduction strip production line

strip production line1, the hot rolling mill structural characteristics and working principle

Hot rolling is based on slabs (mainly continuous casting billets), which are heated to form strips from roughing mills and finishing mills. The hot steel strip from a rolling mill after finishing rolling is cooled to a set temperature by laminar flow, rolled into a steel coil by a coiler, and the cooled steel coil is subjected to different finishing operations according to different needs of users. Lines (flat, straight, cross-cut or slit, inspection, weighing, packaging and marking) are processed into steel, flat and slit steel strips. Because hot-rolled steel sheet products have high strength, good toughness, easy processing and good weldability, they are widely used in ships, automobiles, bridges, construction, machinery, pressure vessels and other manufacturing industries.

With the increasing maturity of new technologies such as hot-rolling dimensional accuracy, plate shape and surface quality, and the advent of new products, hot-rolled steel sheets and strip products have become more and more widely used and are becoming more and more powerful in the market. Competitiveness.Hot rolled steel products include steel strips (rolls) and steel sheets that have been cut.

Contact us will have a very low price, please consult the specific price. firsTfurnace@gmail.com

2 , hot rolling mill selection method

1 , according to its material, performance can be divided into:

a) ordinary carbon structural steel

b) low alloy steel

c) alloy steel

2 , the different uses can be divided into:

a) cold forming steel

b) structural steel

c) Automotive structural steel

d) corrosion-resistant structural steel

e) steel for mechanical structure

f) Welding gas cylinders and steel for pressure vessels

g) steel for pipelines

3 , the advantages and disadvantages of hot rolling

Hot rolling can first eliminate certain defects in the cast metal, such as welding pores, refining coarse grains and changing the distribution of inclusions. The compactness and mechanical properties of the metal are improved. Secondly, the raw material (steel ingot or billet) is increased in thermoplasticity, and the deformation resistance is lowered. Therefore, the amount of deformation can be increased during rolling, which is advantageous for improving productivity. In addition, due to the reduced metal deformation resistance, the requirements for the rolling equipment can be correspondingly lower, so that the cost of the equipment can be reduced and the energy consumption of the motor can be greatly reduced.

The disadvantage of hot rolling is that high temperature rolling produces iron oxide scale, so that the surface quality of the metal is not smooth and clean; the size of the product is not accurate enough, and the mechanical properties are not as good as cold working.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved