Rolling mill detailed introduction

Rolling mill detailed introduction Steel production line detailed introduction

Steel production line detailed introduction Universal mill detailed introduction

Universal mill detailed introduction Pusher detailing

Pusher detailing Four-roll mill detailed introduction

Four-roll mill detailed introduction Three-roll mill detailed introduction

Three-roll mill detailed introduction Hot rolling mill detailed introduction

Hot rolling mill detailed introduction Aluminum casting mill details

Aluminum casting mill details Aluminum magnesium silicon alloy rod continuous casting and r

Aluminum magnesium silicon alloy rod continuous casting and r Six-roll cold rolling mill

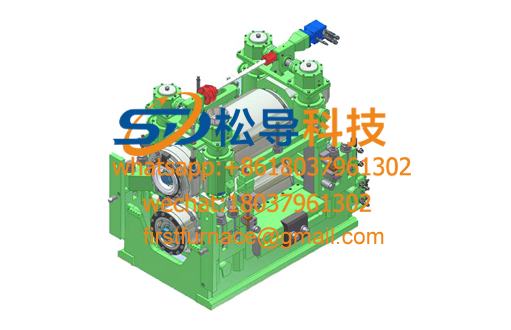

Six-roll cold rolling mill Continuous rolling mill

Continuous rolling mill Cold rolled rebar equipment details

Cold rolled rebar equipment details Detailed introduction of cold rolling steel

Detailed introduction of cold rolling steel Straightening machine details

Straightening machine details Roller table, lifting table details

Roller table, lifting table details Billet fixture

Billet fixture Two-roll cold rolling mill

Two-roll cold rolling mill Short stress rolling mill detailed introduction

Short stress rolling mill detailed introduction Fixed-length cutting machine detailed introduction

Fixed-length cutting machine detailed introduction strip production line

strip production line1 , an overview

The work roll diameter of the six-high mill is small. The intermediate roller can be traversed, and both the work roll and the intermediate roll can be bent, so it is suitable for rolling of metal strips with thin strip rolling and deformation resistance, especially to overcome strip thinning and eliminate any width of the strip. Waves. The basic structure of the six-high mill includes the cvc ̄L machine developed by the German SMS and the HC ¥L machine developed by Hitachi, Japan. Based on the structural characteristics of the cvcSL machine and the HC rolling mill, we have developed a VCMS large-size six-high mill with special technical features and suitable for China's national conditions. The intermediate roller and the working roller of the rolling mill are all flat rollers, and the grinding roller is simple. Except that the intermediate roller can move axially, the intermediate roller and the working roller can both bend the roller, and is equipped with an advanced wedge stepless zero adjusting device and hydraulic AGC. System, work roll precision segmented cooling system.

In addition to the main part, the machine also requires a roll changing device and a track device, and no winding device is required.

Contact us will have a very low price, please consult the specific price. firsTfurnace@gmail.com

2 , six-roll cold rolling mill selection method

Large rolling force: ≥ 1500KN Large rolling torque: 110KNm

Sheet blank thickness: 0.2mm Thin thickness of finished product: 0.01mm

Work roll diameter: ≥ 30mm Large rolling speed: 1m/s

Second work roll diameter: ≥ 60mm Large opening degree: ≥ 2mm

Third work roll diameter: ≥ 200mm Pressing speed: 0.05mm/s

Roller effective width: ≥ 250mm

3 , six-roll cold rolling mill structure characteristics and working principle

The motor of the machine transmits torque to the roller through four parts: gear coupling, reducer, herringbone gear and connecting shaft. The press is hydraulically fine-tuned. In order to ensure the uniform thickness of the plate and the good shape of the plate, the frame should have good rigidity, the roll chocks can be interchanged, and the roll strength should reach the index.

4 , rolling material situation : the main technical parameters of the six-roll cold rolling mill

1. Main technical parameters of rolled metal:

Large width of billet: ≦ 200mm ; large thickness of billet: ≦ 0.2mm ;

Small thickness of finished product: 0.01mm ; Pass processing rate: ≦ 8 %

Total processing rate: ≦ 25 %

Yield strength of rolled metal: ≦ 350Mpa

2 , the basic requirements of the rolling mill:

The rolling speed is adjustable; the pressing system is hydraulic pressure, the control precision of pressing is ≦ 0.06mm/s ; avoiding the padding when the material to be rolled is slag, the HS hardness should be above 95 , the hardness of single-sided quenching ≥ 5mm ; equipped with a hydraulic roll changer; the roll width is less than 250mm .

3 , the main parameters of the roll:

Double-stand reversible continuous rolling, 5 passes rolling, incoming material thickness 0.2mm , width 200mm , material foil, finished thickness 0.01mm

Work roll Φ 40 × 300mm Hs=95~100

Intermediate roller Φ 80 × 300mm Hs=80~85

Support roller Φ 240 × 400mm Hs=50~65

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved