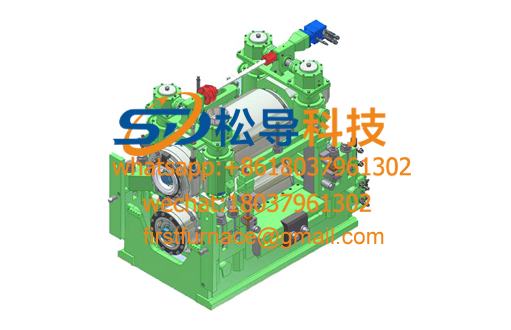

Rolling mill detailed introduction

Rolling mill detailed introduction Steel production line detailed introduction

Steel production line detailed introduction Universal mill detailed introduction

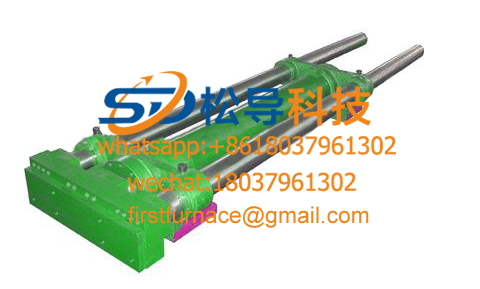

Universal mill detailed introduction Pusher detailing

Pusher detailing Four-roll mill detailed introduction

Four-roll mill detailed introduction Three-roll mill detailed introduction

Three-roll mill detailed introduction Hot rolling mill detailed introduction

Hot rolling mill detailed introduction Aluminum casting mill details

Aluminum casting mill details Aluminum magnesium silicon alloy rod continuous casting and r

Aluminum magnesium silicon alloy rod continuous casting and r Six-roll cold rolling mill

Six-roll cold rolling mill Continuous rolling mill

Continuous rolling mill Cold rolled rebar equipment details

Cold rolled rebar equipment details Detailed introduction of cold rolling steel

Detailed introduction of cold rolling steel Straightening machine details

Straightening machine details Roller table, lifting table details

Roller table, lifting table details Billet fixture

Billet fixture Two-roll cold rolling mill

Two-roll cold rolling mill Short stress rolling mill detailed introduction

Short stress rolling mill detailed introduction Fixed-length cutting machine detailed introduction

Fixed-length cutting machine detailed introduction strip production line

strip production lineI. Overview of the tapping machine

The hot rolling tapping machine belongs to the metallurgical equipment and is mainly used for carrying the billet: the heated billet is removed from the heating furnace and placed on the conveying roller for the next step. The basic action of the hot-rolled tapping machine is the rise and fall of the support arm, and the advancement and retreat of the overall body.

With the in-depth development of energy saving and cost reduction work of major steel mills, in order to adapt to the development plan of the enterprise, the original mechanical tapping machine was changed to a hydraulic type tapping machine, or a new type of hydraulic tapping machine was assembled. Due to the increase in the size of the processed blanks of the enterprise, the thrust of some mechanical tapping machines cannot meet the needs, and the transformation of the original tapping machine becomes inevitable. Considering the poor stability of the original mechanical tapping machine, it is easy to cause Steel runs off, causing steel accidents, unable to adapt to working conditions, high equipment failure rate, seriously affecting production rhythm, complex structure, large space occupation, large total equipment weight, high operating cost, inconvenient maintenance, and difficult maintenance Therefore, it was decided to design a hydraulic type tapping machine to solve the above problems. The hydraulic tapping machine greatly enhances the smoothness of the movement, and the whole device has compact structure, small occupied space, small total weight of the equipment, and convenient maintenance and overhaul.

The CGJ series tapping machine is the metallurgical rolling steel industry. The steel billet that has reached the heating standard in the heating furnace is pushed out to enter the next step. The main equipment is also called the top steel machine.

The device is available in both mobile and fixed versions, and customers can purchase it according to actual needs.

Contact us will have a very low price, please consult the specific price. firsTfurnace@gmail.com

Second, the structure characteristics and working principle of the tapping machine

The CGJ series tapping machine is composed of main components such as motor, reducer, brake, friction roller, water cooling pusher and movable platform. It causes the steel billet in the steel trough to pass through the friction, the roller pushes the water to cool the push rod, pushes the billet to the next step, and enters the tapping roller path. The device has reasonable structure, safety, reliability and convenient operation.

Third, the steel machine selection method summary table

Serial number | name | parameter |

1 | Big thrust | P=1500kg |

2 | Pusher stroke | S=6000mm |

3 | Pusher speed | V=0.222m/S |

4 | motor model | YZR200L-8 |

5 | Reducer model | JZQ500 |

6 | Trolley walking speed | 12m/min |

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved