Rolling mill detailed introduction

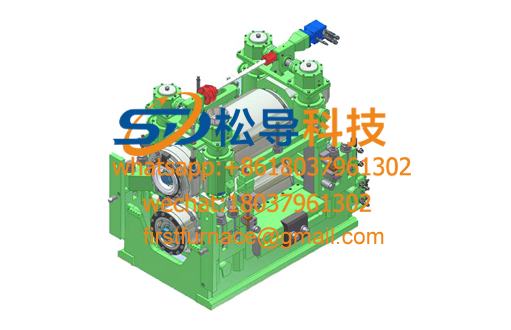

Rolling mill detailed introduction Steel production line detailed introduction

Steel production line detailed introduction Universal mill detailed introduction

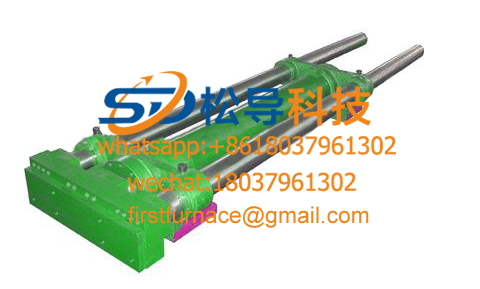

Universal mill detailed introduction Pusher detailing

Pusher detailing Four-roll mill detailed introduction

Four-roll mill detailed introduction Three-roll mill detailed introduction

Three-roll mill detailed introduction Hot rolling mill detailed introduction

Hot rolling mill detailed introduction Aluminum casting mill details

Aluminum casting mill details Aluminum magnesium silicon alloy rod continuous casting and r

Aluminum magnesium silicon alloy rod continuous casting and r Six-roll cold rolling mill

Six-roll cold rolling mill Continuous rolling mill

Continuous rolling mill Cold rolled rebar equipment details

Cold rolled rebar equipment details Detailed introduction of cold rolling steel

Detailed introduction of cold rolling steel Straightening machine details

Straightening machine details Roller table, lifting table details

Roller table, lifting table details Billet fixture

Billet fixture Two-roll cold rolling mill

Two-roll cold rolling mill Short stress rolling mill detailed introduction

Short stress rolling mill detailed introduction Fixed-length cutting machine detailed introduction

Fixed-length cutting machine detailed introduction strip production line

strip production lineOverview of rack stepping cooling bed

The so-called rack step type cooling bed is an important auxiliary equipment in the process of pipe and bar continuous rolling production line. It is an indispensable important component in the production process. The rack step type cooling bed has high speed. The advantages of continuous rolling, slitting and rolling, and automation have been widely used in today's cooling bars, pipes and some small-scale cooling equipment, effectively improving production efficiency. However, due to the complicated structure of the rack step type cooling bed and the large tonnage required in use, the difficulty in manufacturing and installing the rack step type cooling bed is also increased. [1-2]

Rack step type cooling bed manufacturing and installation analysis

The rack step type cooling bed has certain requirements in use, and this will be used as a requirement after the manufacture and installation of the rack step type cooling bed, mainly as follows: static table top, moving table surface and straightening plate device in any position The total plane error shall not be greater than 4 mm , and the straightness shall be inspected by a 5 m inspection round bar. During the inspection at any position, it shall be ensured that no more than two gears are not in contact. If the requirements for the manufacture and installation of the rack step type cooling bed are to be achieved, it is necessary to understand the upper steel skirt, the row of the lower dialing mechanism, and the cooling bed during the manufacture and installation of the rack step type cooling bed. The working principle of the body, the output roller, the roller table, etc., as well as the role played by the various components in the rack step type cooling bed and the specific working position, so as to ensure the stepping cold of the rack The manufacturing quality and installation quality of the bed effectively shorten the commissioning time and meet the production requirements as quickly as possible.

Contact us will have a very low price, please consult the specific price. firsTfurnace@gmail.com

1. Manufacture and installation of upper steel skirt

The main function of the upper steel skirt is to brake the pipe and the bar from the roller conveyor, and to dial it into the first toothed groove in the straightening plate, stepping on the rack The functions in the cooling bed are mainly divided into the cold bed body section and the secondary cooling bed section. Therefore, the braking of the pipe and the bar is also very important, and the effect of the braking effect is mainly the length of the skirt, therefore, During the production and installation process, the length of the skirt must be ensured to meet the corresponding requirements, and the specific length should be adjusted according to the actual working conditions, mainly based on the hydraulic clutch to adjust the length of the skirt, so as to avoid in the production process The appearance of the rear-end of the rolling stock can effectively improve the production efficiency. The drive for dialing the skirt is mainly divided into two types: hydraulic cylinder drive structure, electric motor or hydraulic cylinder pull rod type structure. If the steel structure used for the upper steel skirt is a hydraulic cylinder drive structure, then there will be several uniformly distributed cylinders throughout the steel structure, and the motion synchronization function of the skirt will be realized by electric control or liquid control. In the case of a large number of driving points, the entire long axis is also relatively uniform under the force state, so that the flatness of the working surface of the overall apron is also improved, and it is also convenient in the process of operation. The adjustment of the skirt, under this type, is mainly composed of the hydraulic system of the skirt and the lifting of the conventional device. The hydraulic cylinder is used to realize the manipulation of the cylinder, and the cylinder is operated by the linkage mechanism. The purpose of the skirt is raised to achieve the material to be accessed; if the steel mechanism of the vertical skirt is the motor or hydraulic cylinder rod structure, then the length of the rod used in the model is too long. In this case, a certain accumulation error will be formed in the length of the entire tie rod, and in this case, the surface of the steel skirt is not easy to maintain in the same plane, in order to be effective To avoid this kind of phenomenon, the adjusting screw will be used to adjust the length of the tie rod to meet the installation requirements. However, in the case of this adjustment, it will be affected by the external environment temperature, if the temperature is too high or the upper steel mechanism acts If it is more frequent, it will cause the rod to creep during the use, which will cause the skirt to appear low before the high or high before the high, which will cause the production material pipe or bar to bend, to the production The quality of the material will also have a certain impact, and in this type of working state, the tie rods close to the conventional device may be fatigued, and even the tie rod may be broken. Therefore, it is recommended to use the first type in the manufacture and installation of the steel skirt in the process of manufacturing and installing the progressive rack cooling bed.

2 , manufacturing and installation of steel in the row

The row-discharging mechanism is to realize the pipe or bar to be produced and processed, and the body position of the cooling bed is pushed into the data roller of the cooling bed in a row. The mechanism is mainly composed of a chain type transfer mechanism capable of lifting and lowering, and a step-feeding mechanism of a collecting chain. The chain transfer mechanism capable of lifting and lowering is mainly composed of a sprocket drive, a long-axis conventional device, a cylinder, a bracket, a liftable transport vehicle, The structure of the oil pipe towline and the like; the step chain conveying mechanism of the collecting chain is mainly composed of a sprocket drive, a bracket, a long shaft transmission device and a digital encoder. In the manufacture and installation of the progressive rack cooling bed, it is necessary to pay attention to the 45 steel drive shaft material used in the row of the lower steel dialing mechanism . Moreover, in the process of manufacturing, processing and installation, it is necessary to meet the same requirements of the apron drive shaft. In order to further ensure production efficiency. In addition, after the material is processed, the tooth surface of the sprocket needs to be quenched, and the direction is required to be consistent with the keyway, so that the mutuality can be achieved. In addition, in the process of installing the steel guide mechanism in the row, the main concern is that the direction of the chain guide should be consistent with the direction of the chain lock operation, so as to ensure normal production and install the digital encoder. At the same time, it should be noted that if the installation is in the position of the proximity switch, it is necessary to ensure that the position of the stopper has an adjustable function to avoid the influence between the digital encoder and the switch, and can be carried out according to the specific production environment. Reasonable adjustments ensure the effectiveness of the rack-and-step cooling bed.

3 , the manufacture and installation of the cold bed body

The main body structure of the cooling bed is the main structure of the rack-type cooling bed. In the process of operation, the main step is the rack stepping type, which is the main purpose of material alignment, cooling and transfer. The structure is composed of a device, a static table device, an alignment device, a straightening plate device, and a long shaft transmission device.

1 The moving table device is mainly for the work surface which realizes the material stepping and supports the material. According to the working nature of the structure, in the process of making and installing, it is necessary to ensure that all the moving table surfaces are on the same horizontal surface. The key structures in the operation of the moving table device are mainly the moving table beam, the tug wheel missing, the rack supporting beam and the rack and so on. The machining accuracy of these components is also a key factor affecting the moving table device. Therefore, it is moving. The following aspects should be ensured during the manufacture and installation of the table: the material of the roller is 铸 45 cast steel, and after roughing, it is subjected to quenching and tempering for semi-finishing, but the surface is quenched and then The inner hole serves as a reference for the other parts to be worn into an outer part of the interchangeable part; the raw material used for the rack should be a thick steel plate, and the material should be cut under the numerical control flame and the cutting machine; The table beam, the roller seat and the rack support beam are welded parts of the moving table device, which need to be heat treated before the material is processed to preheat it. In addition to internal stresses present in the welding process.

2 static table device, the same as the moving table device also supports the production of materials, and the static table device needs to hold the material during the second half of the moving table, and the main device for straightening the material, and affecting the static The main components of the table are the accuracy of the rack, the straightening device, the static beam, the static rack and other related devices. Therefore, to ensure the accuracy of the static device operation, it is necessary to pay attention to the manufacture and installation of each component. The static beam needs to be shaped after welding, mainly by vibration and aging to achieve the purpose of eliminating stress, and it is processed by gantry milling until the requirements of the drawings are met; the static rack seat needs to be processed first. It is tempered to ensure that the part is interchangeable.

3 Alignment device, also known as the alignment roller table, is installed above the static table surface and uses the roller channel to drive the material to move. However, when the material head is at the position of the baffle, the material is bumped by the baffle. This process is to lay the foundation of the tidy movement of the materials in order to avoid the jagged phenomenon of the material in the process of moving, which leads to the production effect of the material. The device is mainly composed of a cycloid reducer and a bracket. , roller assembly, sprocket drive and other components. The roller is tempered before processing, and then the surface of the roll surface is quenched and tempered to improve the wear resistance of the roll surface, ensure the operation of the rack step type cooling bed, and improve the production efficiency.

4 Straightening plate device, mainly used for straightening materials and braking work, and affecting the working efficiency of straightening plate device is mainly the error of tooth shape and the phenomenon of over tolerance, which is caused by the appearance of material and the quality of straightness. Direct influence, therefore, in the production and installation of the tooth profile according to the following requirements: gray cast iron material is required as the main material of the straightening plate, and it is necessary to use the gantry planing tool for the secondary treatment. The plate and the special numerical control device are processed, and the batch processing of the component can be realized by using multiple pieces of clamping. Of course, in order to ensure the accuracy of the straightening plate device, the tooth shape accuracy of the template is determined. During the installation process, the specific installation direction should be calibrated along the direction of the incoming steel, in order to ensure the high efficiency of the straightening device in use.

5 long-axis transmission device is mainly used to realize the stepping of the rack. In the use, the main step is to effectively control the stepping distance, in order to accurately realize the function of the device, which is driven by the motor to drive the reduction gear box. Then, combined with the long axis of the eccentric wheel, the moving table device pressed on the eccentric wheel is pushed to achieve the stepping effect. In the process of installing the device, the offset direction of the eccentric wheel of the long drive shaft is mainly controlled, and the setting is strictly performed according to the specific offset direction, and it is necessary to ensure that the eccentric wheel supports the entire moving table surface, so that In order to ensure that the dynamic surface is on a normal working height plane, in order to reduce the accuracy of the long-axis transmission, it is necessary to carry out the following requirements in the production: the long drive shaft should use 45 steel as the main material, and should be used in the production process. The same batch of round steel is produced. The specific manufacturing and installation requirements are almost the same as those of the skirt shaft. The material used for the eccentric wheel in the long drive shaft should be 45 cast steel, and the eccentricity should be guaranteed. The eccentric distance of the wheel and the direction of the keyway must be consistent. Firstly, the rough processing is performed on it. However, the material is adjusted and then finely processed. The inner hole is used as the reference for grinding, and the processed parts are guaranteed. It is interchangeable, and at the same time, it is necessary to perform high frequency quenching on the outer surface of the worn surface, which can ensure and improve the long transmission. The service life of the shaft material.

4 , the manufacture and installation of the roller table

The function of the roller conveyor is mainly to divide the produced finished materials into multiple pieces, then transfer them to the accelerated roller table, and pull the adjacent two pieces of material apart by a certain distance. It is possible to transfer the wrong head to the cold bed to avoid the impact of the front and rear collisions and affect the working efficiency of the cold bed. Roller consists of two parts acceleration roller and an output roller, etc., in the process of its fabrication and installation, it is noted that the acceleration rollers needs 0 ° to 12 ° before entering the apron roller, in the production The materials to be used are mainly made of gray cast iron. In the production, the cast iron needs to be processed in a fine manner, and some dynamic balance experiments are to be quenched until they are qualified, and the quenching process needs to be warm quenched. To deal with it, this can ensure and improve the wear resistance and comprehensive mechanical properties of the equipment, and also guarantee the operation efficiency of the progressive rack cooling machine. During the normal operation of the machine, it is necessary to ensure that the rollers of the input roller table are inclined at a certain angle. Therefore, in the process of installing them, the following points should be noted: it is necessary to ensure that the various roller faces of the installation are kept in the same Above the water level; the center position of the roller needs to be secured above the centerline of the roller table, and the error between the rollers should not exceed 0.5 mm ; it needs to be calibrated by a level gauge, etc. Calibration is carried out to ensure the accuracy of the roller table installation, so as to ensure that the material is produced without too much error, thereby improving the production efficiency of the progressive rack cooling bed.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved