Flywheel ring gear high frequency quenching equipment

Flywheel ring gear high frequency quenching equipment Fully automatic gear high frequency quenching equipment

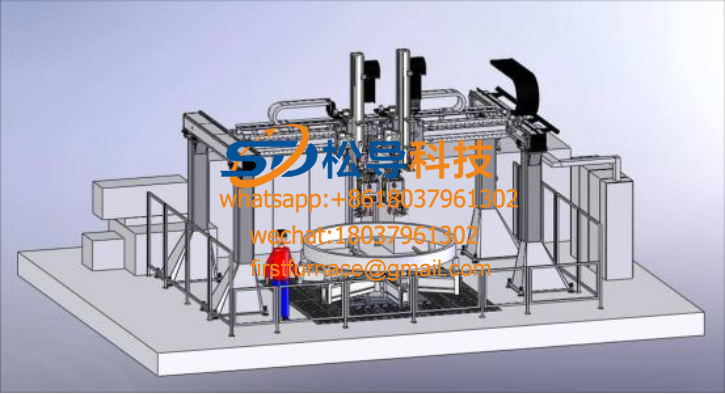

Fully automatic gear high frequency quenching equipment Vertical numerical control induction hardening equipment

Vertical numerical control induction hardening equipment Vertical high frequency quenching equipment

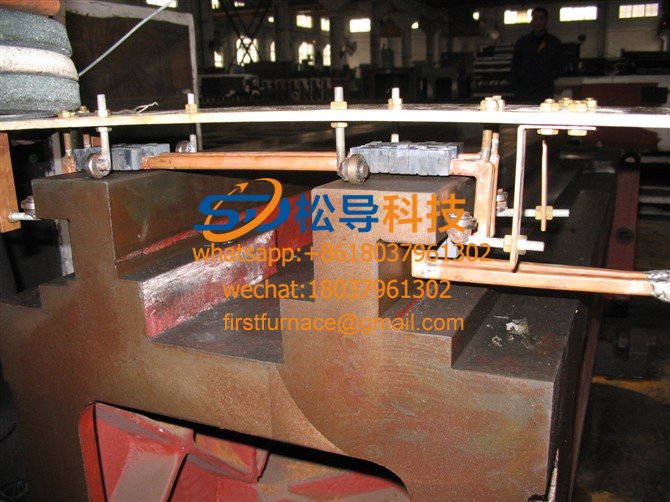

Vertical high frequency quenching equipment  Machine tool guide table surface quenching equipment

Machine tool guide table surface quenching equipment Machine tool guide quenching equipment

Machine tool guide quenching equipment Piston rod quenching special equipment

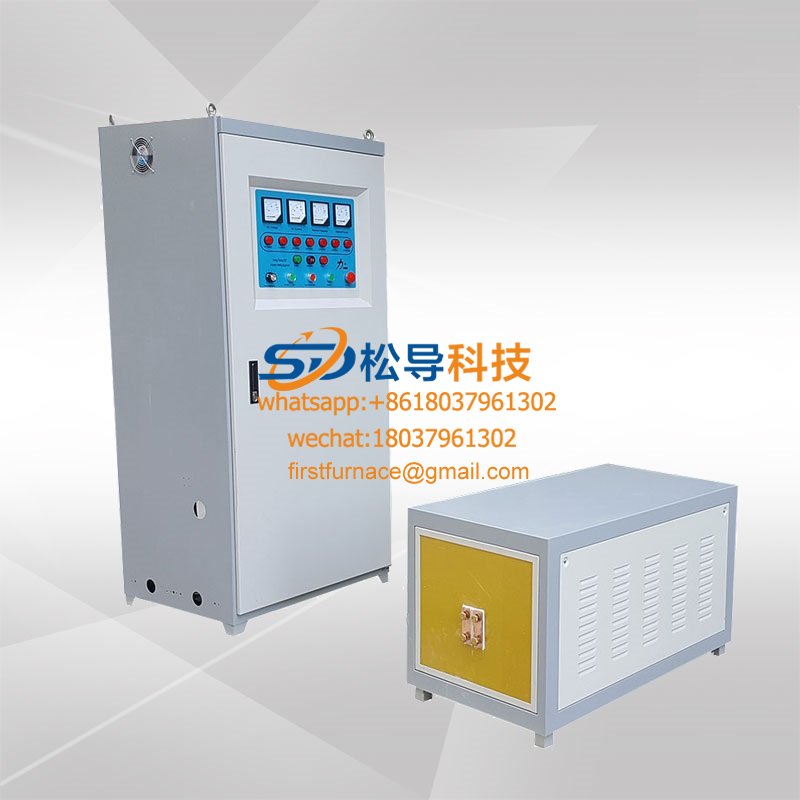

Piston rod quenching special equipment  High frequency quenching equipment

High frequency quenching equipment Induction hardening equipment

Induction hardening equipment Pump tube inner wall quenching equipment

Pump tube inner wall quenching equipment  Pump tube inner wall quenching equipment

Pump tube inner wall quenching equipment Milling machine guide quenching equipment

Milling machine guide quenching equipment Medium frequency induction hardening equipment

Medium frequency induction hardening equipment Ball flat steel 350KW/4KHZ quenching equipment

Ball flat steel 350KW/4KHZ quenching equipment Quenching equipment

Quenching equipment gear intermediate frequency quenching equipment

gear intermediate frequency quenching equipment lathe guide quenching equipment

lathe guide quenching equipment 400KW/4KHZ quenching equipment configuration options

400KW/4KHZ quenching equipment configuration options pump tube quenching equipment

pump tube quenching equipmentModel: pump tube quenching machine

Input power: 160KW

Input voltage: 380V

Oscillating frequency: 15-25KHz

Application areas:

Concrete pump tube 160 within bore induction hardening apparatus may be satisfactory for the diameter of the inner bore 125 of the concrete pump tube quenching, concrete pump delivery pipe wall quenching equipment induction hardening, low loss, high dielectric coaxial structure sensors, inductive length 5 Meter, concretepump tube quenching hardness can reach HRC55 , concrete pump tube quenching large travel speed 300-400 / min, concrete pump tube inner wall hardened layer is 1.5-1.8mm

Delivery tube within the wall of the induction hardening apparatus induction hardening concrete pump apparatus

1, the inner wall of the concrete pumping performance of the induction hardening apparatus described

Concrete pump tube 200 within bore induction hardening apparatus may be made to the diameter of the inner bore 125 of the pump tube concrete hardening, concrete pump delivery pipe wall quenching equipment induction hardening, low loss, high dielectric coaxial structure sensors, inductive length 7 m, Concrete pump tube quenching hardness can reach HRC55 , concrete pump tube quenching large travel speed 500-600 / min, concrete pump tube inner wall hardened layer is 1.5-1.8mm ,

2 , the role of high-frequency wall quenching equipment on the inner wall of concrete pump conveying pipe

The concrete pump tube is made of special material steel tube, which is quenched by internal wall and carburized chemical treatment. The hardness of the flange bushing reaches 58-60 degrees, and the service life of the pipeline is increased by 3-5 times, which saves users time and expense. The trouble of frequent replacements increases production efficiency. No concrete pump tube quenching and hardening of concrete pump pipe performance and life is not the same, through the concrete pump tube quenching can convey more than the last few million cubic meters of concrete.

Third, the concrete pump inner wall quenching machine is composed.

1 , IGBT super audio power supply

2. A set of tooling matched with the power supply: the quenching of the inner wall of the pump tube is required to be uniform during quenching, and the pump tube is required to move at a uniform speed along the shaft. When the pump tube is tilted during quenching, the water during quenching can flow out.

3 , coaxial water-cooled sensor system: This sensor is designed by our company for pump tube quenching. Water is sprayed while quenching to ensure that the pump tube is not deformed.

Fourth, the main technical selection method of high-frequency quenching equipment for concrete pump conveying pipe inner wall : input power 200KVA, three-phase 380 ± 10, oscillation frequency 50-60HZ 25-35KHZ, cooling water pressure ≥ 0.05MPa weight 450kg host volume 1450 × 480 × 1000mm3 extension 500 × 600 × 1000mm3

PREV:No More Articles.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved