Flywheel ring gear high frequency quenching equipment

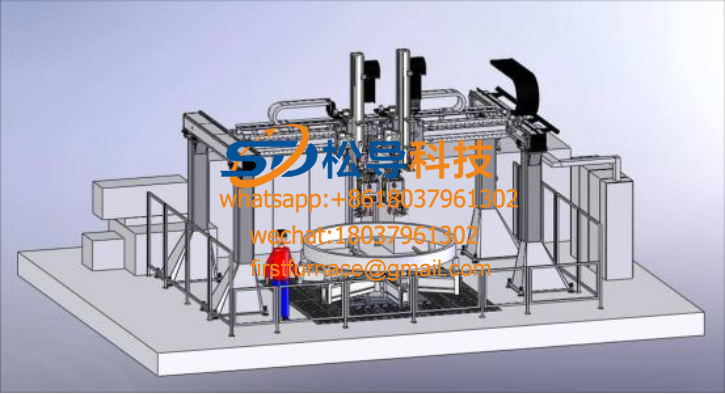

Flywheel ring gear high frequency quenching equipment Fully automatic gear high frequency quenching equipment

Fully automatic gear high frequency quenching equipment Vertical numerical control induction hardening equipment

Vertical numerical control induction hardening equipment Vertical high frequency quenching equipment

Vertical high frequency quenching equipment  Machine tool guide table surface quenching equipment

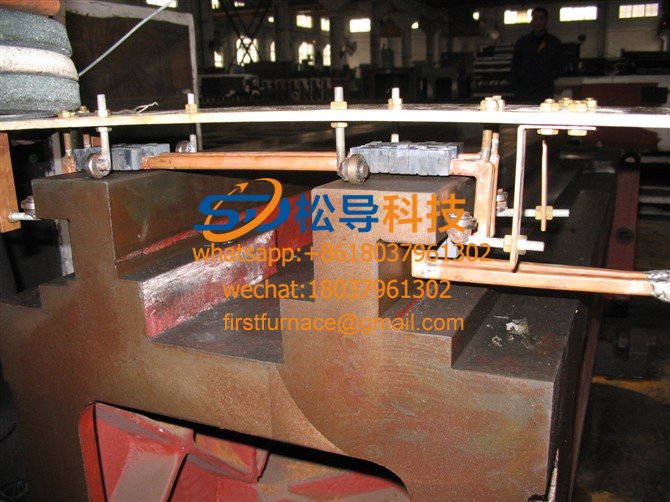

Machine tool guide table surface quenching equipment Machine tool guide quenching equipment

Machine tool guide quenching equipment Piston rod quenching special equipment

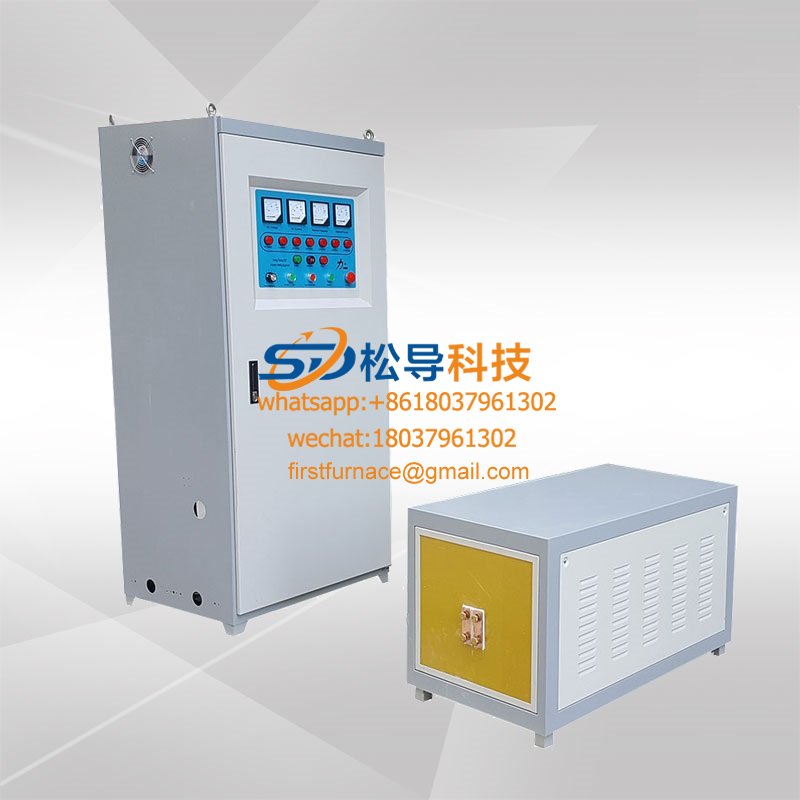

Piston rod quenching special equipment  High frequency quenching equipment

High frequency quenching equipment Induction hardening equipment

Induction hardening equipment Pump tube inner wall quenching equipment

Pump tube inner wall quenching equipment  Pump tube inner wall quenching equipment

Pump tube inner wall quenching equipment Milling machine guide quenching equipment

Milling machine guide quenching equipment Medium frequency induction hardening equipment

Medium frequency induction hardening equipment Ball flat steel 350KW/4KHZ quenching equipment

Ball flat steel 350KW/4KHZ quenching equipment Quenching equipment

Quenching equipment gear intermediate frequency quenching equipment

gear intermediate frequency quenching equipment lathe guide quenching equipment

lathe guide quenching equipment 400KW/4KHZ quenching equipment configuration options

400KW/4KHZ quenching equipment configuration options pump tube quenching equipment

pump tube quenching equipmentFirst, the application : the complete set of equipment has continuous quenching, simultaneous quenching, segmental continuous quenching, segmentation and quenching, etc., mainly used for semi-axle, drive shaft, camshaft, spline shaft, gear shaft and other shaft parts Surface quenching, induction quenching of gears, rings, sprockets and flat parts.

Second, the main selection of piston rod quenching special equipment :

Induction heating power supply, quenching machine, water cooling system and inductor are composed of four parts. The surface of the piston rod can be quenched and heat treated. It can also be used with other equipment to form a production line. The quenching effect is quite good.

Third, the performance characteristics of the special equipment for piston rod quenching:

1. Fast heating: The fastest heating speed of the complete set of piston rod quenching equipment is less than 1 second, and the heating speed can be adjusted and controlled.

2 , power consumption: thermal efficiency of more than 95% , so compared to other heating methods (such as gas, oxygen, acetylene, coking coal, electric furnace, high-frequency tube, etc.) are energy-saving.

3 , the effect is good: the surface of the workpiece is heated evenly, the temperature rises quickly, and the degree of deformation of the oxide layer and the workpiece on the surface of the workpiece is reduced.

4 , wide application: special equipment for piston rod quenching can heat metal workpieces. (Induction loops are made according to the shape of the workpiece)

5 , less land: the equipment is small, light weight, occupying less than half a cubic space, easy to move and move.

6. Good environmental protection: no noise, pollution and open flame, it is easier to meet the requirements of environmental protection and fire protection.

7 , easy to operate: CNC design, the whole machine does not require debugging, installation, operation is very convenient, you can learn in 5 minutes.

8. High efficiency: The complete set of equipment for piston rod quenching has automatic setting function, and the operation can be completed by one person, thus reducing the number of processes and improving efficiency.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved