Flywheel ring gear high frequency quenching equipment

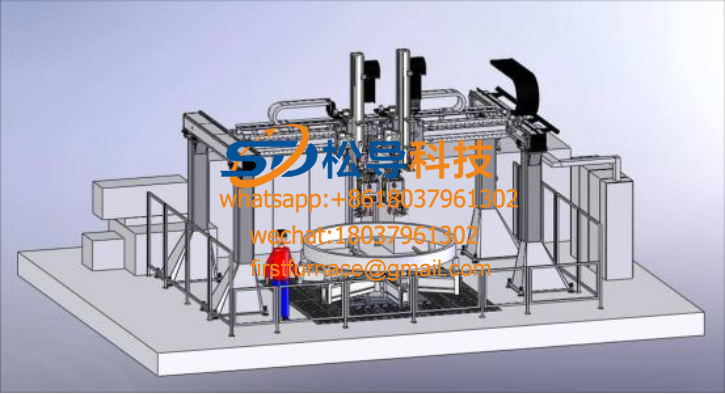

Flywheel ring gear high frequency quenching equipment Fully automatic gear high frequency quenching equipment

Fully automatic gear high frequency quenching equipment Vertical numerical control induction hardening equipment

Vertical numerical control induction hardening equipment Vertical high frequency quenching equipment

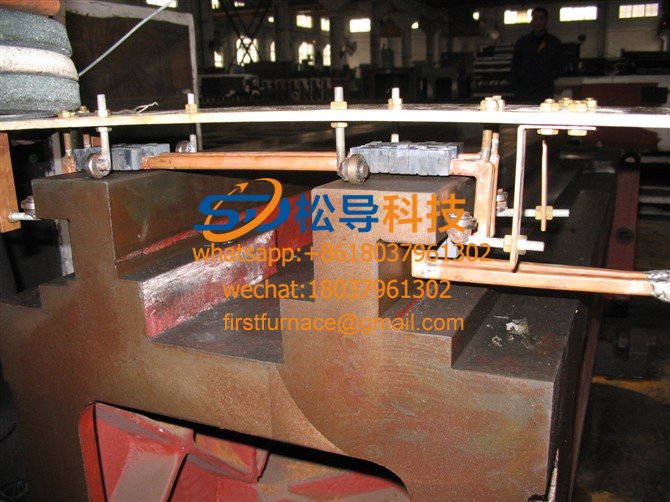

Vertical high frequency quenching equipment  Machine tool guide table surface quenching equipment

Machine tool guide table surface quenching equipment Machine tool guide quenching equipment

Machine tool guide quenching equipment Piston rod quenching special equipment

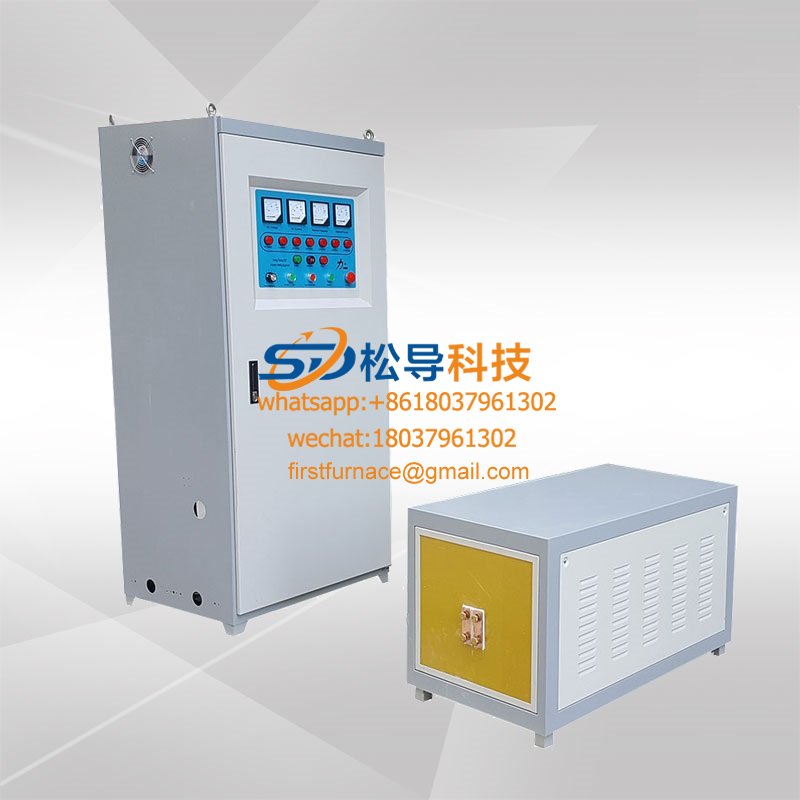

Piston rod quenching special equipment  High frequency quenching equipment

High frequency quenching equipment Induction hardening equipment

Induction hardening equipment Pump tube inner wall quenching equipment

Pump tube inner wall quenching equipment  Pump tube inner wall quenching equipment

Pump tube inner wall quenching equipment Milling machine guide quenching equipment

Milling machine guide quenching equipment Medium frequency induction hardening equipment

Medium frequency induction hardening equipment Ball flat steel 350KW/4KHZ quenching equipment

Ball flat steel 350KW/4KHZ quenching equipment Quenching equipment

Quenching equipment gear intermediate frequency quenching equipment

gear intermediate frequency quenching equipment lathe guide quenching equipment

lathe guide quenching equipment 400KW/4KHZ quenching equipment configuration options

400KW/4KHZ quenching equipment configuration options pump tube quenching equipment

pump tube quenching equipmentI. Overview, Model: SD -CHJ

Power: 15-160KW

Shaft type: φ10-300mm L: 50-1500mm

Gear type: φ20-300mm H: 10-600mm

Vertical high-frequency quenching equipment application range: suitable for quenching and tempering of various workpieces, such as induction quenching of shafts, gears, discs and other parts.

Second, the introduction of vertical high-frequency quenching equipment

1. It is suitable for quenching and tempering of various workpieces, such as induction quenching of shafts, gears, guide rails, discs, pins, and other parts;

2. It has the functions of continuous quenching, quenching, continuous quenching, segmentation and quenching at the same time;

3. The CNC system or PLC and variable frequency speed control system are used to realize workpiece positioning and scanning, and the PLC and the induction power supply are connected to realize fully automated production.

4. Vertical (shaft parts quenching) + horizontal (ring ring parts quenching)

Third, the main technical parameters selection method of vertical high-frequency quenching equipment

power | 10KW-300KW (with multiple specifications of induction power supply for induction hardening) |

Quenching method | Continuous quenching, simultaneous quenching, segmental continuous quenching, segmentation and simultaneous quenching |

Quenching length | 2500mm |

Quenching diameter | 1200mm |

Quenching weight | 500kg |

X- axis travel | 200mm |

Y- axis travel | 300mm |

Z- axis travel | 1500mm |

Fourth, the performance characteristics of vertical high-frequency quenching equipment

1 , CNC system, can prepare and store a variety of quenching process procedures according to different workpiece requirements;

2 , With energy saving, environmental protection, intelligent, automatic, less oxidation, less deformation and so on;

3 , The control precision and the degree of automation are high, the consistency of the workpiece quality after heat treatment is good, and the quench hardened layer is consistent;

4, no manual adjustment during quenching, quenching equipment automatically, high heating efficiency, low labor intensity;

5 , It has the functions of continuous quenching, simultaneous quenching, segmental continuous quenching, and simultaneous quenching;

6, using the workpiece moves, can realize continuous scan quenching parts quenching, quenching scan segment, the segment through the entire work hardening;

7 , Stepless adjustable: quenching speed, working speed; process / equipment display

Fifth, the performance characteristics of vertical CNC quenching machine:

1. The vertical CNC quenching machine has advanced performance, convenient debugging and use, and can meet the quenching needs of complex workpieces to the greatest extent.

2 , energy saving: vertical CNC quenching machine tools use IGBT international advanced components, energy saving, energy saving, and reduce costs. The efficiency is 30%~40% higher than the old thyristor IF .

3 , a variety of quenching methods: continuous scanning quenching, simultaneous quenching, segmental continuous scanning quenching (segment by program setting, no need to switch), segmentation and simultaneous quenching, etc. can be achieved;

4 , adaptability: vertical CNC quenching machine is self-propelled, especially suitable for larger and heavier guide rails: such as gantry milling, gantry planing, large lathes, etc., as well as various machine tool accessories such as machine tool beds. Quenching treatment. Can heat a wide variety of workpieces.

5 , the vertical CNC quenching machine has the same bed calibration, no need to change the head;

6. Environmental protection: no pollution, noise and dust;

7. The vertical CNC quenching machine has complete protection measures, low failure rate, stable performance and no worries;

8. The control cabinet and the transformer cabinet are integrated, and the complete design system of the whole design is walked together to reduce the support caused by the power line and the water pipe, so that the workshop layout is neat and orderly. The workpiece is fixed, easy to install, convenient to operate the platform, and flexible to move.

9. Configuring a unique cooling system: The coolant of the integrated quenching liquid circulation cooling system is a car coolant, which solves the problems of long time, inconvenience and freezing in the winter. Fully enclosed circulation cooling to avoid blockage caused by debris; overheating damage caused by power supply, induction coil, etc. caused by no scale formation.

10 , three-dimensional movement direction: the machine can do: horizontal movement, vertical movement, up and down movement and other self-movement. It overcomes the movement of the machine tool itself when it is used, and solves the hidden dangers of the customer's work tooling, inconvenience, long time and so on.

11. High-precision, high-quality and high-efficiency quenching process: A. High quenching accuracy: The gap between the inductor and the guide surface is designed to be adjusted by an adjustable guide wheel to avoid contact between the sensor and the bed surface. Fire, the gap is always fixed, the temperature and heating time can be accurately controlled, the movement is smooth, the temperature is uniform; B. The quenching quality is high: no oxide layer, small deformation, hardened layer depth and hardness is about 2~4 MM , also Can be determined according to the manufacturer's process requirements. If the material isHT200-HT300 , the hardness is HRC48~53 . Quenching hardness and moderate hardness layer; C. high quench efficiency: two-track may quench 200 ~ 400MM / min; if the track is too wide, made unilateral quenching sensor, if the track is narrow face, a quench can be bilateral;

|

|

|

Vertical quenching equipment induction heater | Vertical quenching equipment is being quenched | Comparison before and after quenching of gears |

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved