Flywheel ring gear high frequency quenching equipment

Flywheel ring gear high frequency quenching equipment Fully automatic gear high frequency quenching equipment

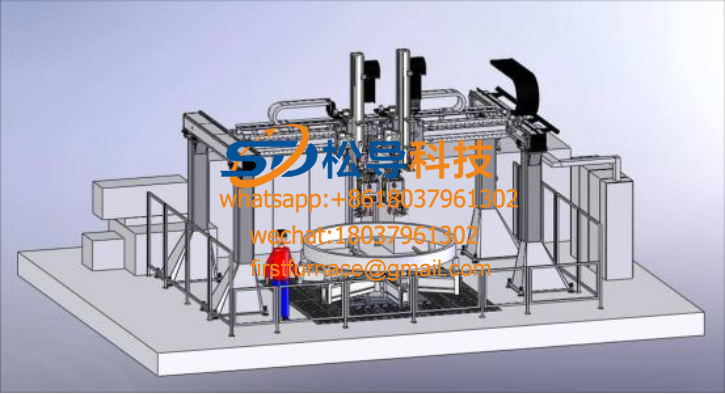

Fully automatic gear high frequency quenching equipment Vertical numerical control induction hardening equipment

Vertical numerical control induction hardening equipment Vertical high frequency quenching equipment

Vertical high frequency quenching equipment  Machine tool guide table surface quenching equipment

Machine tool guide table surface quenching equipment Machine tool guide quenching equipment

Machine tool guide quenching equipment Piston rod quenching special equipment

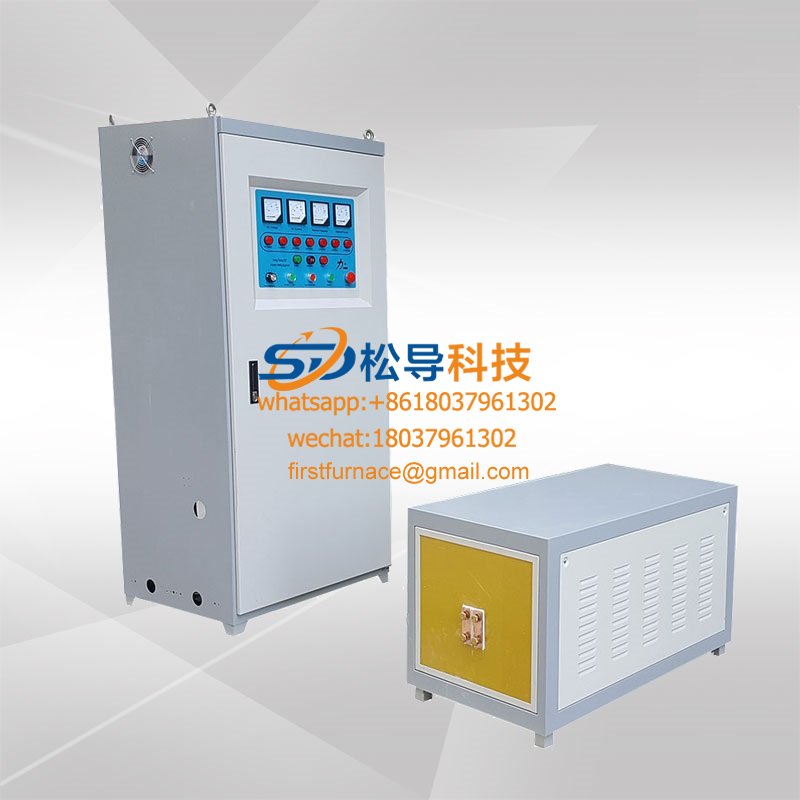

Piston rod quenching special equipment  High frequency quenching equipment

High frequency quenching equipment Induction hardening equipment

Induction hardening equipment Pump tube inner wall quenching equipment

Pump tube inner wall quenching equipment  Pump tube inner wall quenching equipment

Pump tube inner wall quenching equipment Milling machine guide quenching equipment

Milling machine guide quenching equipment Medium frequency induction hardening equipment

Medium frequency induction hardening equipment Ball flat steel 350KW/4KHZ quenching equipment

Ball flat steel 350KW/4KHZ quenching equipment Quenching equipment

Quenching equipment gear intermediate frequency quenching equipment

gear intermediate frequency quenching equipment lathe guide quenching equipment

lathe guide quenching equipment 400KW/4KHZ quenching equipment configuration options

400KW/4KHZ quenching equipment configuration options pump tube quenching equipment

pump tube quenching equipmentInduction Hardening equipment consists of a horizontal surface hardening quenching bed, a pulse frequency power supply 6 KGPS- 250 KW / 2.5 KHZ frequency power supply, a frequency quenching transformer and inductor, PLC automatic control system.

The system has the characteristics of stable and reliable, precise control and complete protection functions. It can accurately control the surface of the heated workpiece to ensure that the surface quenching temperature and temperature difference after heating reach the required temperature range (± 25 °C).

It has a good man-machine interface, which can control the parameters such as temperature and speed of surface quenching during operation; display the parameters such as frequency, power, surface quenching heating temperature and speed of the power supply ; temperature rise of surface quenching , power supply Power distribution, etc. are set; parameters such as surface quenching various state parameters such as temperature batch number after heating are recorded and periodically sent to the management level.

I. Selection of process parameters for medium frequency induction hardening equipment

Pre-quenching parameters:

Finished product diameter: Φ 114-229 mm, inner hole Φ 45-70 mm, tilt angle 3-4

Quenching ramp length: 2000-3600 mm arc radius R135-150mm

Hardening depth : 10-15mm Surface hardness: HRC= 45-50 Quenching temperature: 860 °C ± 20 °C;

Second, the main electrical parameters selection of medium frequency induction hardening equipment

1. Main parameters of intermediate frequency power supply

Input voltage: 380V

DC voltage: 500V

DC current: 1600A

IF voltage: 1400V

IF frequency: 1000Hz ± 10%

IF power: 25 0KW/set

2. Capacitor cabinet parameters

2.5KZ Hz electric heating capacitor

Model: RFM 0.75 — 2 000 — 2.5 S

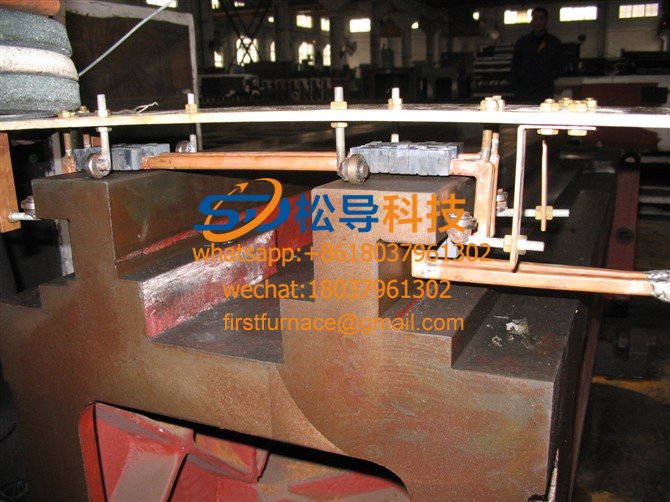

3. The sensor is: GTR- 2 00, the sensor is a flat heating sensor with a rectangular tube and a magnet .

4. Quenching transformer

In order to achieve the matching of the intermediate frequency resonance, a quenching transformer must be connected before heating the inductor.

The PR type quenching transformer is composed of a core and a primary secondary winding. The iron core is made up of 0.2-0.3mm thick high-magnetic imported silicon steel sheets (3K pieces). The iron core cooling adopts a water jacket type structure, and the transformer has strong overload capability, which is especially suitable for long-term continuous operation. The winding coils are wound in an overlapping manner, and the turns ratio is changed more, and the original paying side can be arbitrarily combined into odd-even ratios according to needs, and the load adaptability is strong. The specific parameters are as follows:

model | capacity | Matching intermediate frequency power | Primary side ratio | Secondary side ratio | Adaptive frequency |

PR- 1000 | 10 00KVA | 250 KW | 25~7 | 1 to 2 | 1~8KHz |

Third, surface quenching horizontal quenching bed selection

The bed body having a continuous quenching of CNC systems, segmented continuous quenching, quenching at the same time segment, while quenching functions for surface hardening of parts and the plane of the cylindrical surface.

The bed body has manual operation and fully automatic operation function . It is suitable for single and batch parts production . It is widely used in the field of induction heat treatment of tractors , automobiles , engineering machinery and bed industry . It has reasonable structure , complete functions and convenient installation and debugging .

Bed by the bed main portion and a transmission system, the mask frame, NC electrical parts and other components.

( 1) Bed body part: The bed body adopts welded bed structure, and the whole body is subjected to stress relief annealing . The structure is reasonable , stable and reliable . The surface of the main exposed parts is specially treated and has good anti-rust and anti-corrosion properties .

(2) Transmission System: shaft driven by a stepper motor. It adopts frequency conversion speed regulation technology and adjusts speed according to process requirements, which can be adjusted steplessly.

(3) Part clamping adjustment mechanism: the use of special tools clamping parts, to achieve an accurate positioning and clamping the workpiece.

(4) block mask: the mask frame made of steel plate well, appearance, color and appearance both outer cooling water splashing is prevented, and easy handling and monitoring components quenching process...

( 5) Electrical control part : The electrical control part is composed of numerical control system , frequency converter , intermediate relay and programmable controller . The power supply line : 3 phase , 380V, 2.5Kw. It can store more than 20 kinds of parts. Quenching process , through the numerical control keyboard can program and store various programs . The bed is equipped with power failure protection , water shortage protection and other functions , with high safety and reliability .

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved