Flywheel ring gear high frequency quenching equipment

Flywheel ring gear high frequency quenching equipment Fully automatic gear high frequency quenching equipment

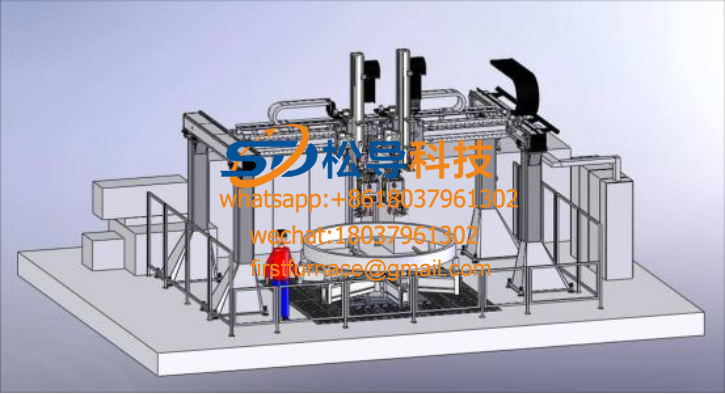

Fully automatic gear high frequency quenching equipment Vertical numerical control induction hardening equipment

Vertical numerical control induction hardening equipment Vertical high frequency quenching equipment

Vertical high frequency quenching equipment  Machine tool guide table surface quenching equipment

Machine tool guide table surface quenching equipment Machine tool guide quenching equipment

Machine tool guide quenching equipment Piston rod quenching special equipment

Piston rod quenching special equipment  High frequency quenching equipment

High frequency quenching equipment Induction hardening equipment

Induction hardening equipment Pump tube inner wall quenching equipment

Pump tube inner wall quenching equipment  Pump tube inner wall quenching equipment

Pump tube inner wall quenching equipment Milling machine guide quenching equipment

Milling machine guide quenching equipment Medium frequency induction hardening equipment

Medium frequency induction hardening equipment Ball flat steel 350KW/4KHZ quenching equipment

Ball flat steel 350KW/4KHZ quenching equipment Quenching equipment

Quenching equipment gear intermediate frequency quenching equipment

gear intermediate frequency quenching equipment lathe guide quenching equipment

lathe guide quenching equipment 400KW/4KHZ quenching equipment configuration options

400KW/4KHZ quenching equipment configuration options pump tube quenching equipment

pump tube quenching equipmentFirst, the choice method of the lathe guide quenching equipment :

1. Rated power: 80KW and 120KW are used for quenching of lathe guide rails, which is convenient for applications such as larger section lathe guide rails and gear quenching.

2 , walking speed: double rail together quenching: 200-400mm / min (depending on the size of the section) as the original lathe factory, the old-fashioned 100KW thyristor intermediate frequency walking speed of 140mm / min. Use our company's lathe guide quenching machine to walk at a speed of 300mm/ min.

3 , lathe rail quenching equipment type 120 hardened layer depth: 2-4mm or so, and can be determined according to the manufacturer's process parameters.

Second, the lathe guide quenching equipment outstanding features:

1 . The high frequency quenching layer is too shallow, the intermediate frequency quenching layer is too deep and easy to deform. Our company's super audio equipment is suitable for rail quenching. And the quenching layer is moderate, the speed is fast, and the double rails are quenched at one time.

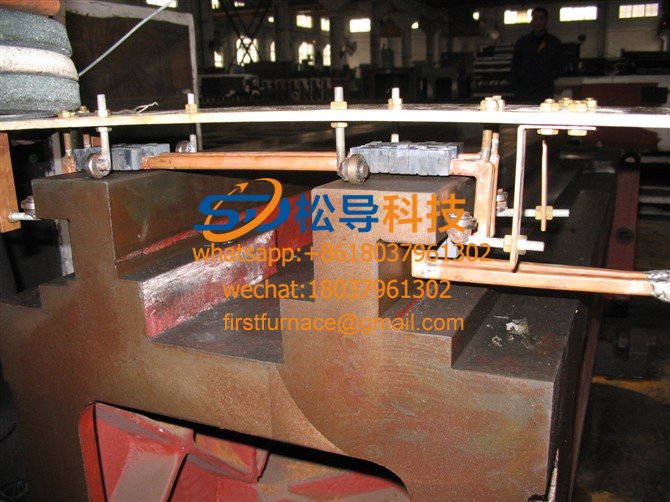

2 . The sensor connection structure is simple and convenient, the gap is easy to adjust, the guide wheel is positioned to avoid sparking.

3 . The control cabinet is integrated with the transformer cabinet, which is convenient to install, convenient for the platform and flexible to move.

4. The machine has three-dimensional motion, which solves the hidden troubles of the customer's work tooling, inconvenience, long time and so on.

5. The machine has its own cooling system, and the coolant is the car coolant. This solves the problems of long time, inconvenience and freezing in the winter.

6 . This machine is self-propelled, especially suitable for larger and heavier guide rails and bed surfaces, such as gantry milling, gantry milling, large lathes, etc.

7 . It is also suitable for quenching of lathe attachments such as various lathe beds .

Third, the lathe guide quenching equipment consists of four major parts:

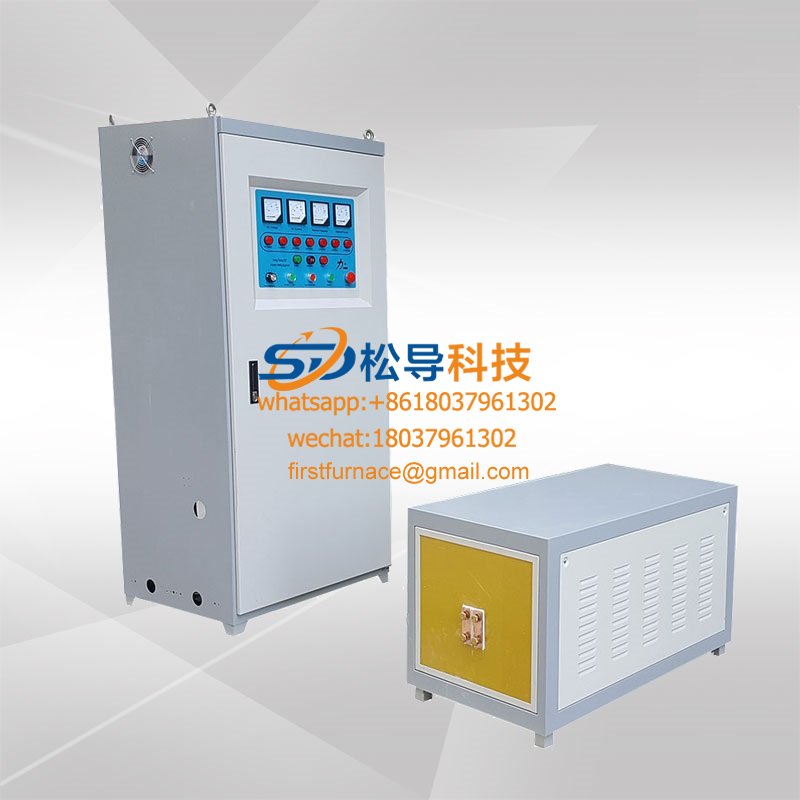

1 ) IGBT super audio power supply;

2 ) AG-1 high-precision lathe guide special quenching train bed ;

3 ) BZ-1 self-propelled quenching train bed ;

4 ) Chiller.

4, machine tool guide quenching machine contains what?

Induction heating equipment is applied to the machine tool guide quenching machine. The equipment is a combined design , including: machine tool quenching equipment quenching power cabinet, transformer cabinet, internal circulation cooling system, together with sensors, quenching machine, etc. The workpiece is fixed.

Fifth, the heat treatment of the surface of the machine tool rail is finally used.

Surface hardening of machine tool guide rails is usually performed by medium frequency or high frequency surface quenching + low temperature tempering heat treatment.

If the depth of the hardened layer is required (the depth of the hardened layer is 2 to 10 mm ), medium frequency quenching is required. If the hardened layer is required to be shallow (hardened layer depth is 0.5 to 2.5 mm ), high frequency quenching is used.

5, lathe track hardness standard is how much?

1. Cast iron : HT200 , high phosphorus cast iron, low alloy cast iron, HT300 ;

2. Steel : general track search: 45 steel, 40Cr , T8A , T10A , GCr15 , GCr15SiMn and other surface quenching or full quenching; high requirements of the guide rail, often used 20Ce , 20CrMnTi , 15 steel, etc., carburizing hardened to 56~ 62HRC , the hardening depth after grinding is not less than 1.5mm;

3. Non-ferrous metals : brass HPb59-1, tin bronze : ZCuSn6Pb3Zn6, aluminum bronze : ZQAl9-2, etc .;

4. Plastic : PTFE, epoxy resin wear-resistant coating

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved