Flywheel ring gear high frequency quenching equipment

Flywheel ring gear high frequency quenching equipment Fully automatic gear high frequency quenching equipment

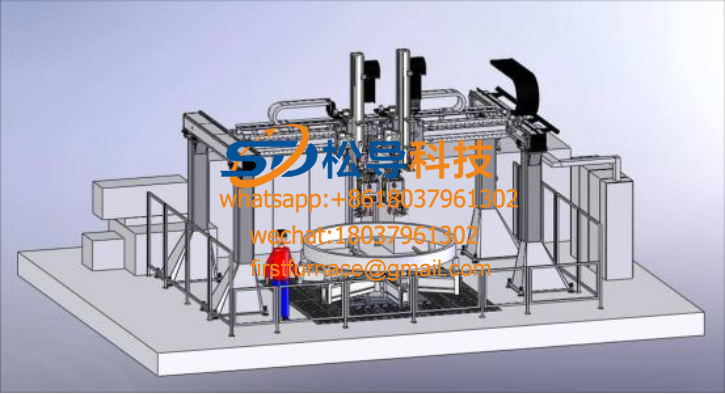

Fully automatic gear high frequency quenching equipment Vertical numerical control induction hardening equipment

Vertical numerical control induction hardening equipment Vertical high frequency quenching equipment

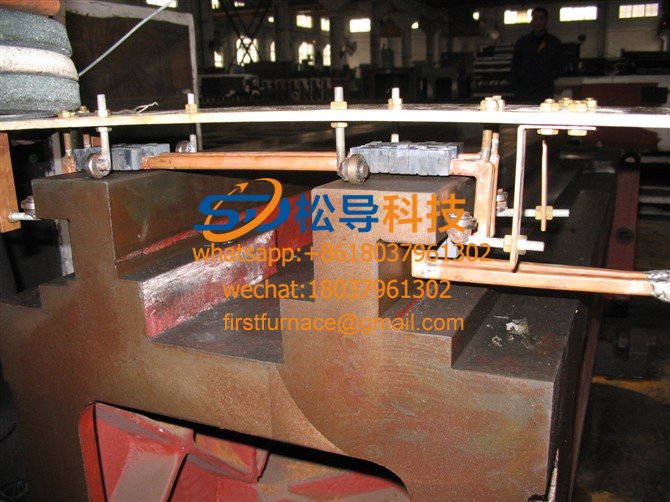

Vertical high frequency quenching equipment  Machine tool guide table surface quenching equipment

Machine tool guide table surface quenching equipment Machine tool guide quenching equipment

Machine tool guide quenching equipment Piston rod quenching special equipment

Piston rod quenching special equipment  High frequency quenching equipment

High frequency quenching equipment Induction hardening equipment

Induction hardening equipment Pump tube inner wall quenching equipment

Pump tube inner wall quenching equipment  Pump tube inner wall quenching equipment

Pump tube inner wall quenching equipment Milling machine guide quenching equipment

Milling machine guide quenching equipment Medium frequency induction hardening equipment

Medium frequency induction hardening equipment Ball flat steel 350KW/4KHZ quenching equipment

Ball flat steel 350KW/4KHZ quenching equipment Quenching equipment

Quenching equipment gear intermediate frequency quenching equipment

gear intermediate frequency quenching equipment lathe guide quenching equipment

lathe guide quenching equipment 400KW/4KHZ quenching equipment configuration options

400KW/4KHZ quenching equipment configuration options pump tube quenching equipment

pump tube quenching equipmentI. Overview

1. Equipment name: induction hardening equipment

2 , equipment use description:

The equipment is mainly used for semi-axis induction hardening treatment;

2.1 Main dimensions of the workpiece:

Maximum length of shaft: 1000 mm;

Maximum diameter of shaft: 400 mm;

Maximum weight of parts: 100Kg; specific heating parts are provided by the buyer;

Process description: The quenching machine adopts a single-station structure. The control system adopts the well-known domestic single - axis servo control system, manual loading and unloading parts, and the quenching process program is automatically controlled. During the quenching process, the display screen displays the workpiece work progress in real time, and the machine tool has energy monitoring function, which is convenient, intuitive and reliable.

Parts quenching process: manual parts - part rotation (deceleration motor drive), sensor in place - quenching power supply starts to heat, while the spray solenoid valve opens the spray - workpiece continuous movement (servo motor drive) - power supply stops after quenching - Solenoid valve closed - part rotation stopped - parts in place - manual replacement parts to start the next production.

Second, the induction quenching equipment structure selection

CNC Vertical induction hardening equipment mainly GCHT1000 CNC hardening machine bed, 2 0 0KW / 4 KHz monitor power energy, induction heating load, water cooling system, control cabinet, sensors and other components.

1 , machine tool

The machine adopts CNC numerical control system with continuous quenching , segmental continuous quenching , simultaneous quenching , and quenching . It is suitable for surface quenching of various shaft parts such as semi-axle , rotating shaft and camshaft . Gears , rings and Induction hardening of planar parts .

The machine has manual operation and fully automatic operation function . It is suitable for single and batch parts production . It is widely used in the field of induction heat treatment of tractors , automobiles , engineering machinery and machine tools . It has reasonable structure , complete functions and convenient installation and debugging .

The main machine of the machine consists of the bed part , the skateboard , the slide movement and transmission system , the spindle rotation and transmission system , the upper and lower top assembly , the counterweight balance , the cover frame , and the electrical control part .

( 1 ) . The bed part: the machine tool adopts the welded bed structure, and the whole body is subjected to stress relief annealing . The bed sliding guide rail is a well-known rectangular guide rail , which has good anti-rust performance . After the skateboard is finished , the movement precision can be effectively ensured , the structure setting is reasonable , stable and reliable . The surface of the main exposed parts is specially treated and has good anti-rust and anti-corrosion properties .

(2). Skateboard moving system : The servo motor drives the ball screw to realize the lifting movement of the skateboard . The moving speed is steplessly adjustable , the transmission is light , the guiding precision is high , and the positioning is accurate .

(3) Rotating system : driven by an asynchronous motor through a shifting mechanism and a drive shaft. Spindle rotation . Adopt frequency control technology , set the speed according to the process requirements , the speed can be adjusted steplessly .

. (4) on the top seat adjustment mechanism: The clamping workpieces of different lengths by adjusting the position of the top of the lead screw and the drive transmission mechanism, so that asynchronous motors.

(5) block mask: the mask frame made of steel plate well, appearance, color and appearance of the mask frame provided on the upper sliding door and windows, to prevent the cooling water splashing outside, and easy handling and monitoring components quenching process. .

(6) electrical control: the electrical control by the numerical control system, an energy monitoring system, inverter, relays or programmable controllers and other components, the power line: 3-phase, 380V, 2.5Kw may store two more than 10 kinds of parts hardening process, the keyboard may be performed by a variety of numerical control programming stored. beneath electrical machine provided protection, offside protection, water protection, etc., having high safety and reliability.

( 7 ) . Counterweight system: The machine tool uses the counterweight to connect with the slide plate through the sprocket chain to reduce the working load of the motor and make the workpiece move up and down lightly. The machine tool mainly consists of bed body, skateboard moving mechanism , base, cover frame, internal pipeline, hydroelectric towline and control system .

Selection of main technical indicators for quenching machine tools

Serial number | Project | Unit | Parameter | Remarks |

1 | Maximum part height | Mm | 1000 | |

2 | Maximum part diameter | Mm | 400 | |

3 | Spindle rotation speed | r / min | 0 to 200 | |

4 | Number of spindles | 1 | ||

5 | cooling method | Spray | ||

6 | Control System | Single axis servo system |

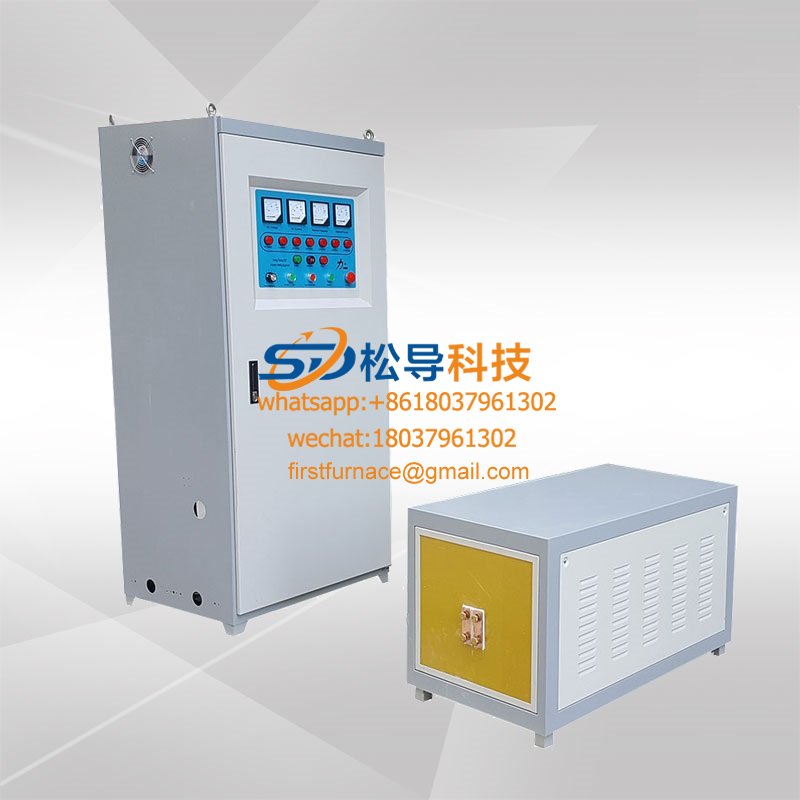

2 , induction hardening equipment power supply selection

The power supply adopts a thyristor parallel resonant circuit, and the real-time operating data of the device is realized by the single-chip microcomputer to achieve the purpose of energy monitoring, and the device maintains constant power output.

The intermediate frequency transformer uses a ferrite core. Compared with the efficiency of the silicon steel sheet, the efficiency is improved by more than 5% , the structure is simple, the water path is small, and the failure rate is low.

Serial number | Project | Parameter | Remarks |

1 | Power line voltage | 380V, 50Hz | |

2 | Rated intermediate frequency voltage | 750V | |

3 | Rated DC current | 400 A | |

4 | rated power | 2 00KW | |

5 | Rated intermediate frequency | 1000 - 4 000 HZ |

3 , induction quenching equipment circulating cooling system selection

The machine and power supply use two separate, fully enclosed cooling units. The purpose of using two sets of cooling devices independent of each other is to avoid mutual influence. There is a water collecting tray under the cooling tower, and the spraying water is installed inside. The water inlet of the water collecting tray is equipped with a floating ball valve, which can automatically control the water level in the water collecting tray, and the water outlet has a spray water pump. Because the intermediate frequency power supply and the machine tool and quenching liquid require low temperature cooling water, the outlet water temperature should be controlled within 55 ° C. The core of the fully enclosed cooling device is the spray evaporative closed cooling tower. There are many heat-dissipating coils inside the cooling tower, and circulating water flows inside the coils without coming into contact with the air. The upper part of the cooling tower is equipped with a water spout and a cooling fan. During operation, the spray pump will pump the water to the upper spout, spray the water onto the outer surface of the coil, and the cooling fan will simultaneously draw air to vaporize the spray water and take away the heat of the circulating water in the coil. This advanced type of cooling unit has a high heat exchange efficiency.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved